When it comes to high-performance 3D printing, the Creality K2 Plus and Bambu Lab P1S stand out as two formidable contenders. Both machines boast impressive features designed to cater to professionals and hobbyists seeking precise, multicolor, and versatile printing solutions. To find out which printer emerges as the ultimate champion, we put them through their paces across 18 critical categories. Here’s the breakdown, based on first-hand experience.

Creality K2 Plus

Released: 2024 July

Key Features: 350 × 350 × 350 mm³ | Die-cast aluminum “Matrix” frame | Actively heated chamber (60 °C) | CFS (16-color system) | 30,000 mm/s² acceleration | Dual AI cameras | High-flow hotend (350 °C) | Strain gauge leveling | Air purifier | USB, Wi-Fi & Ethernet

Price Range:Starts with $1,299

Bambu Lab P1s

Released: 2023 Aug

Key Features: 256 × 256 × 256 mm³ | Fully enclosed chamber | AMS (16-color printing) | 20,000 mm/s² acceleration | Carbon filter | Built-in 720p camera | All-metal hotend (300 °C) | Auto bed leveling | Direct-drive extruder | Wi-Fi & Bluetooth

Price Range:Starts with $699

First Impressions

The Bambu Lab P1S makes an immediate impact with its sleek, compact design. With the tempered glass enclosure and simple finishes, it looks like a box that should be plugged in and start running immediately. Everything arrives perfectly, thanks to the well thought out packaging with protective materials. Convenient bonuses such as a starter filament spool and unclogging tools make for an easy out-of-the-box experience. Its 256 x 256 x 256 mm build volume might seem modest compared to larger machines, but the overall presentation screams accessibility and polish.

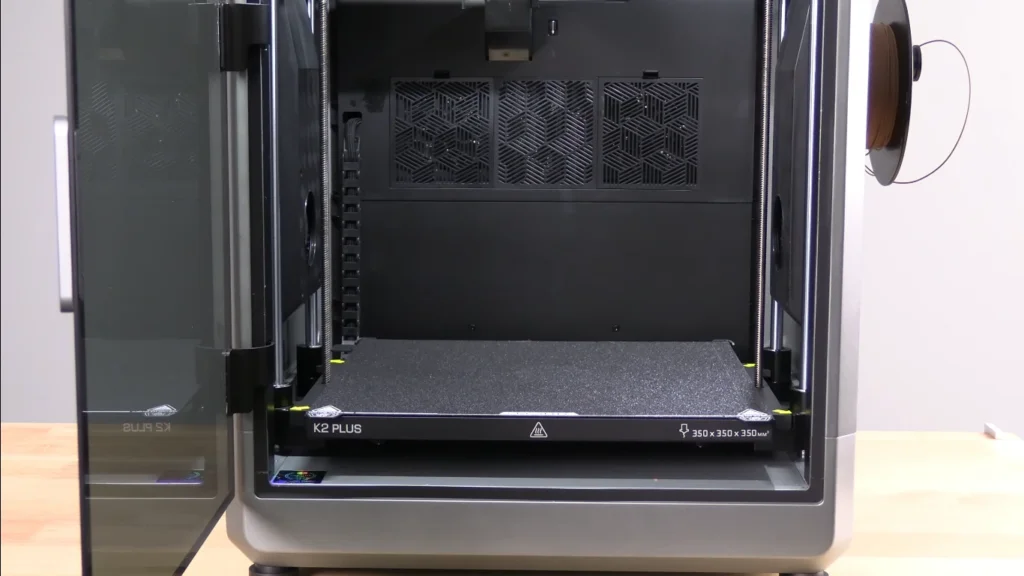

However, the Creality K2 Plus goes big and has a huge 350 x 350 x 350 mm of build volume. Its aluminum die-cast frame radiates durability, making it clear this is a printer built for serious work. The enclosure is functional, incorporating features like a heated chamber for advanced material handling. While the setup involves handling several hefty components, everything is well-organized, and the scale of the machine speaks to its capability for professional-grade projects. Between the two, the Bambu Lab P1S wins for its user-friendly, polished introduction.

Winner: Bambu Lab P1S nails portability and elegance.

Setup and Ease of Use

Setting up the Bambu Lab P1S is refreshingly simple. Within 15 minutes, it’s ready to print thanks to its nearly pre-assembled design. With features like automatic bed leveling and vibration compensation built in, beginners and advanced users alike can dive right into printing without worrying about fine-tuning. The accompanying app and intuitive display streamline calibration and filament loading, emphasizing an approachable experience.

Conversely, the Creality K2 Plus demands more effort during setup due to its larger scale and more complex features like the CFS (Creality Filament System). The machine requires assembly of components like the screen, filament unit, and various bolts. However, its quick guide helps mitigate potential confusion, and experienced users will appreciate the additional control. For beginners, the Bambu Lab P1S is the clear choice for ease of setup, while the K2 Plus might better suit those who enjoy hands-on preparation.

Winner: Bambu Lab P1S. Its streamlined setup wins over the heavier, more labor-intensive K2 Plus.

Creality K2 Plus vs Bambu Lab P1S Comparison Chart

| Feature | Bambu Lab P1S | Creality K2 Plus |

|---|---|---|

| Build Volume | 256 x 256 x 256 mm | 350 x 350 x 350 mm |

| Max Print Speed | 500 mm/s | 600 mm/s |

| Max Acceleration | 20,000 mm/s² | 30,000 mm/s² |

| Maximum Nozzle Temperature | 300°C | 350°C |

| Maximum Bed Temperature | 100°C | 120°C |

| Chamber Temperature | Not specified | Up to 60°C |

| Multi-color Capability | Up to 16 colors (4x AMS) | Up to 16 colors (4x CFS) |

| Frame Construction | Steel chassis | Die-cast aluminum alloy |

| Motor System | Standard | FOC Step-servo motors |

| Camera System | Single camera (720p) | Dual AI cameras |

| Enclosure | Plastic & glass | Full enclosure with air purifier |

| Weight | 12.95 kg | 35 kg |

| Key Features | – Quick 15-min setup – Direct drive extruder – Carbon filter – Auto bed leveling | – RFID filament detection – Active belt tensioning – Dual AI monitoring – Ethernet + dual-band WiFi |

| Supported Materials | PLA, PETG, TPU, ABS, ASA, PA, PC | PLA, ABS, PETG, PA-CF, PLA-CF, PET, ASA, PPA-CF |

| Price | Starting at $699; Combo with AMS priced at $949. | Starting at $1,299; Combo packages available up to $2,259.99. |

Print Quality and Speed

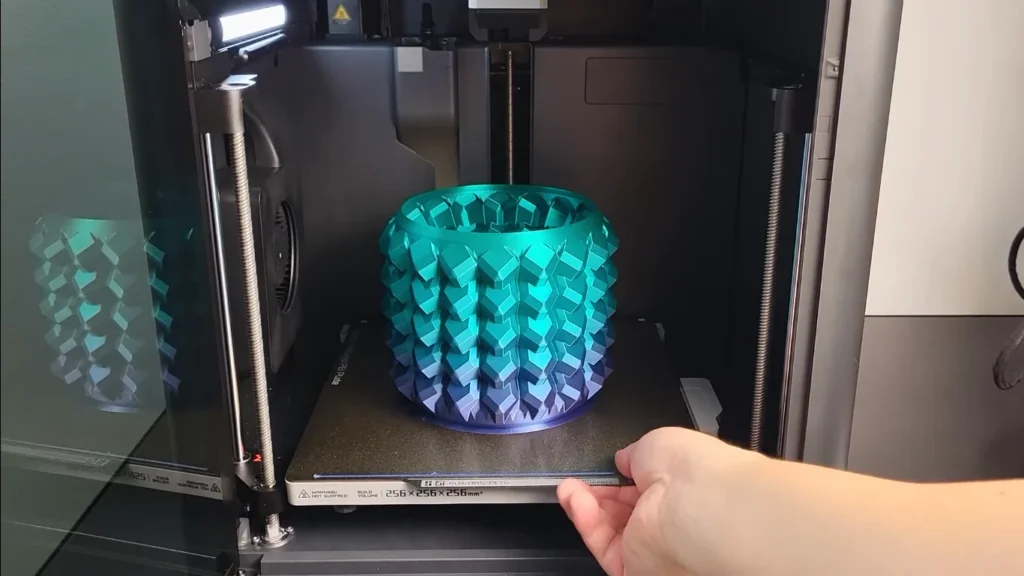

The Bambu Lab P1S excels in print speed, completing a standard benchy in just 18 minutes while maintaining impressive detail and accuracy. Its built-in vibration compensation ensures minimal defects, even at high speeds. The prints showcase smooth finishes and accurate overhangs, proving its mettle in detailed and functional models alike. Whether using PLA or PETG, the P1S delivers consistent, high-quality results.

The Creality K2 Plus pushes the envelope with even greater speed capabilities, achieving 600 mm/s and a remarkable 30,000 mm/s² acceleration. Its hardened steel nozzle and high-flow hotend contribute to exceptional performance with various materials, including composites like carbon fiber. Larger models, like a 300 mm tall castle, demonstrate its ability to handle intricate designs at scale. While both machines impress in quality, the K2 Plus edges ahead in versatility and speed for industrial-scale projects.

Winner: Creality K2 Plus is unmatched for scale and strength, while the P1S wins in finesse and fine details.

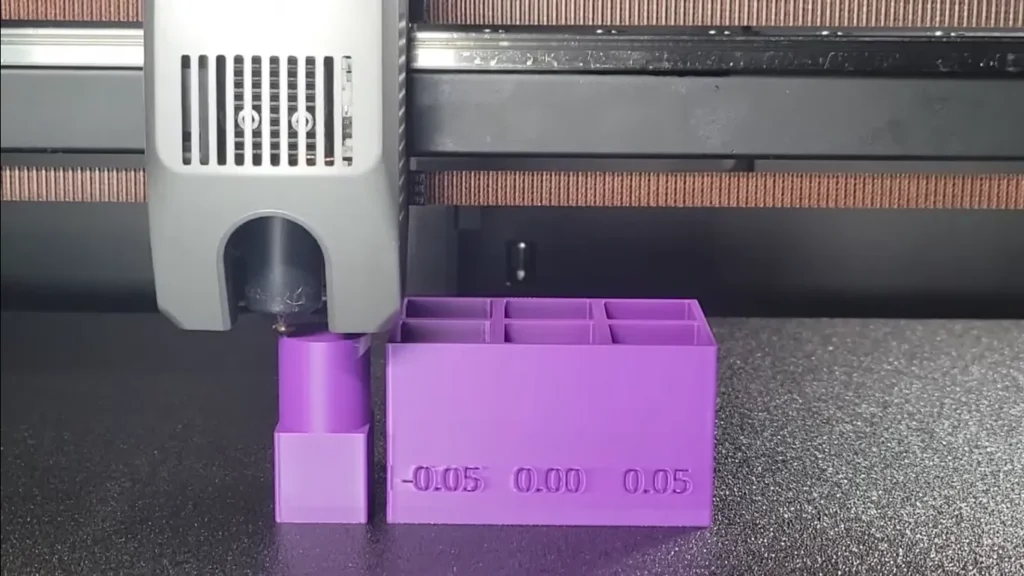

Build Plate and Adhesion

The Bambu Lab P1S features a PEI-coated flexible build plate that offers excellent adhesion for PLA and PETG. The textured surface ensures models stay firmly in place during printing, while the flexibility makes removal hassle-free. Although it lacks the advanced heating capabilities of some high-end machines, its performance with standard materials remains dependable.

The Creality K2 Plus raises the stakes with a 5 mm thick aluminum alloy heatbed that retains heat efficiently and minimizes deformation. The PEI spring steel sheet provides exceptional adhesion and supports high-temperature materials like ABS and ASA without warping. Additionally, the actively heated chamber ensures consistent results, even for challenging prints. Thanks to its advanced thermal features, the K2 Plus emerges as the winner in this category.

Winner: Creality K2 Plus. Its higher temperature range and durability make it a better choice for challenging materials.

Extruder Design and Precision

The Bambu Lab P1S incorporates a direct-drive extruder with an all-metal hotend capable of reaching 300°C, enabling precise extrusion and retraction. It handles flexible materials like TPU with minimal issues, though its compatibility with engineering-grade filaments is somewhat limited. The extruder’s durability ensures consistent performance over extended use.

Meanwhile, the Creality K2 Plus leverages its next-gen extruder system with hardened steel gears and a high-temp nozzle that reaches 350°C. This design enables faster filament changes, better wear resistance, and compatibility with abrasive materials like carbon fiber. The strain gauge for leveling further enhances accuracy, delivering flawless first layers. For advanced material compatibility and durability, the K2 Plus takes the lead.

Winner: Creality K2 Plus – Its robust extruder system provides better support for a wide range of materials and higher durability.

Cooling Systems and Thermal Management

Cooling is a strong suit for the Bambu Lab P1S, which utilizes an auxiliary cooling fan and chamber regulator to manage internal temperatures effectively. This ensures stable prints, even during rapid operations. While the fan setup supports most common materials, the system struggles slightly with high-temperature filaments like ABS.

The Creality K2 Plus, on the other hand, features dual auxiliary fans that deliver powerful airflow, minimizing stringing and warping. Coupled with its actively heated chamber, the printer maintains a controlled environment up to 60°C, crucial for high-performance materials. Its superior cooling capabilities ensure a flawless finish across a broader range of materials, giving it the edge in thermal management.

Winner: Creality K2 Plus – Its actively heated chamber and enhanced cooling fans ensure superior performance for high-temperature materials.

Multicolor and Material Capabilities

The Bambu Lab P1S, equipped with its AMS (Automatic Material System), allows for up to 16 colors when using multiple AMS units. This feature, coupled with an intuitive filament management system, simplifies multicolor printing, producing vibrant and seamless transitions. However, the AMS compatibility is limited to specific Bambu models, restricting scalability.

The Creality K2 Plus brings its A-game with the CFS (Creality Filament System), supporting up to 16 colors via daisy-chained units. Its automated filament cutter and RFID-tagged filaments streamline multicolor projects, offering precise transitions with minimal waste. With broader filament compatibility and industrial-level scalability, the K2 Plus dominates in this category.

Winner: Creality K2 Plus – Its superior material compatibility and multicolor capacity make it a powerhouse for professionals.

Material-Specific Features

The Bambu Lab P1S performs admirably with standard materials like PLA, PETG, and TPU. While it advertises support for ABS, the 100°C bed temperature falls slightly short of the ideal range, leading to challenges with more demanding filaments. The direct-drive extruder ensures consistent performance with flexible filaments, making it a solid choice for general-purpose use.

By contrast, the Creality K2 Plus shines as a master of materials. Its 350°C hardened steel nozzle, actively heated chamber, and advanced cooling fans enable seamless printing with high-performance filaments like carbon fiber-reinforced nylon, ASA, and PET-CF. Its ability to handle exotic materials with precision and stability makes it a clear winner for professional applications requiring specialized results.

Winner: Creality K2 Plus – Its superior material compatibility sets it apart for demanding applications.

User Interface and Software

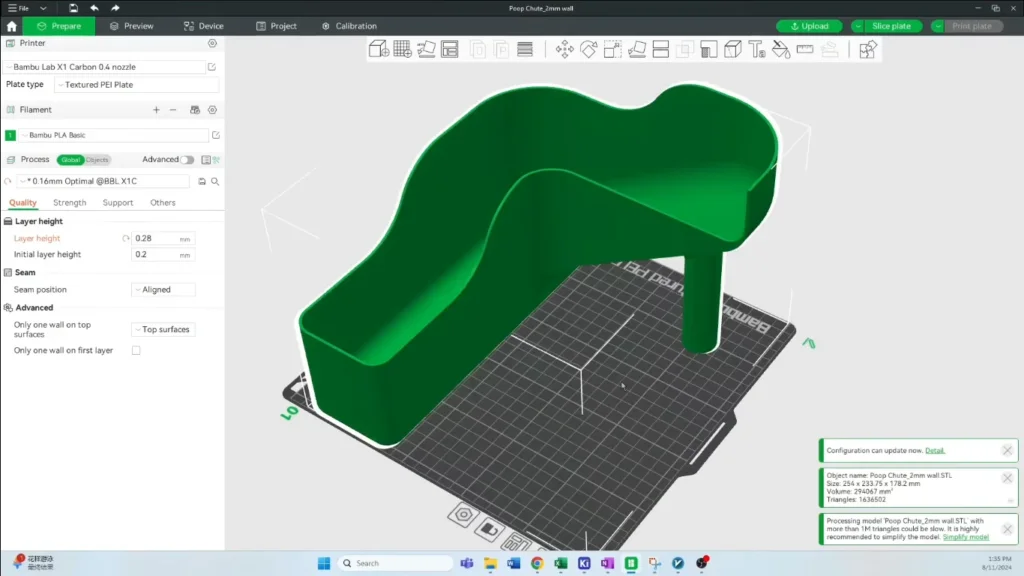

The Bambu Lab P1S features a clean and intuitive interface accessible via its touchscreen, Bambu Studio slicer, or mobile app. The software is user-friendly, with features like remote monitoring, automatic calibration, and cloud integration for streamlined workflows. While it excels in accessibility, some advanced users may find the lack of customizable slicer settings limiting.

The Creality K2 Plus offers a robust 4.3-inch touchscreen and an upgraded Creality Print 5.0 slicer. Its advanced slicing presets, multicolor management, and LAN-based multi-printer control provide flexibility for experienced users. Creality OS includes expert modes for fine-tuning, catering to both casual and professional needs. The depth of customization and seamless workflow options give the K2 Plus a slight edge.

Winner: Creality K2 Plus – Its user-friendly software ecosystem and connected features offer a superior experience.

Advanced Features and Automation

The Bambu Lab P1S impresses with features like auto bed leveling, vibration compensation, and a filament runout sensor, all of which ensure consistent performance. The AMS unit automates material switching, reducing manual intervention. While advanced, the P1S relies on proprietary systems that may feel restrictive to some users.

The Creality K2 Plus steps up with pro-level automation, including active belt tensioning, strain gauge leveling, and filament tangle detection. Dual AI cameras monitor prints in real time, providing error detection and flow rate calibration. The integration of advanced sensors for thermal, motion, and extrusion monitoring ensures unparalleled reliability, making it the standout performer.

Winner: Creality K2 Plus – Its advanced sensors and monitoring systems cater to professionals needing detailed oversight.

Timelapse and Monitoring

The Bambu Lab P1S includes a built-in camera for timelapses and remote monitoring via the Bambu Handy app. While functional, its 720p resolution and 5 fps output limit the quality of captured footage. Still, it remains a useful addition for tracking progress and sharing results.

The Creality K2 Plus elevates this with dual AI cameras one monitoring the chamber and another on the toolhead. The system captures high-quality timelapse videos and detects potential failures like stringing or warping in real time. This dual-camera setup not only enhances monitoring but also improves print accuracy through advanced flow calibration. The K2 Plus is the clear winner in this department.

Winner: Creality K2 Plus – Its AI-powered monitoring and high-quality imaging provide better oversight for complex projects.

Build Volume and Workspace Requirements

With a build volume of 256 x 256 x 256 mm, the Bambu Lab P1S suits hobbyists and light prototyping. Its compact design makes it ideal for smaller workspaces, offering high performance without demanding excessive room. However, for larger projects, its build area may feel limiting.

The Creality K2 Plus provides a substantial 350 x 350 x 350 mm build volume, perfect for large-scale models or batch production. While its size and weight (99 lbs) require significant workspace, the added capacity is invaluable for industrial and creative endeavors. For professionals and ambitious creators, the K2 Plus offers unmatched versatility.

Winner: Creality K2 Plus – The unmatched build volume caters to ambitious projects and high-output needs.

Noise Levels and Efficiency

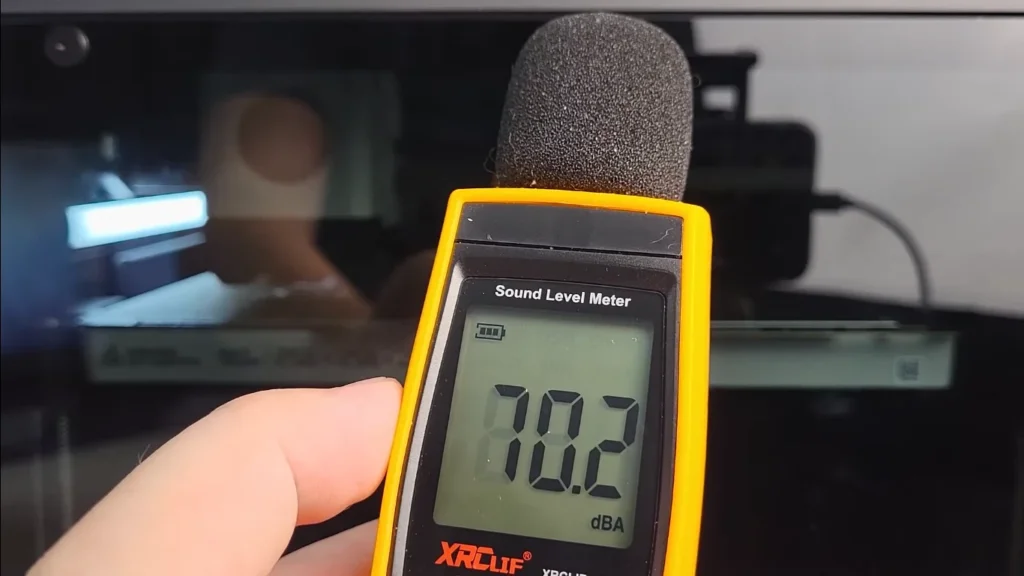

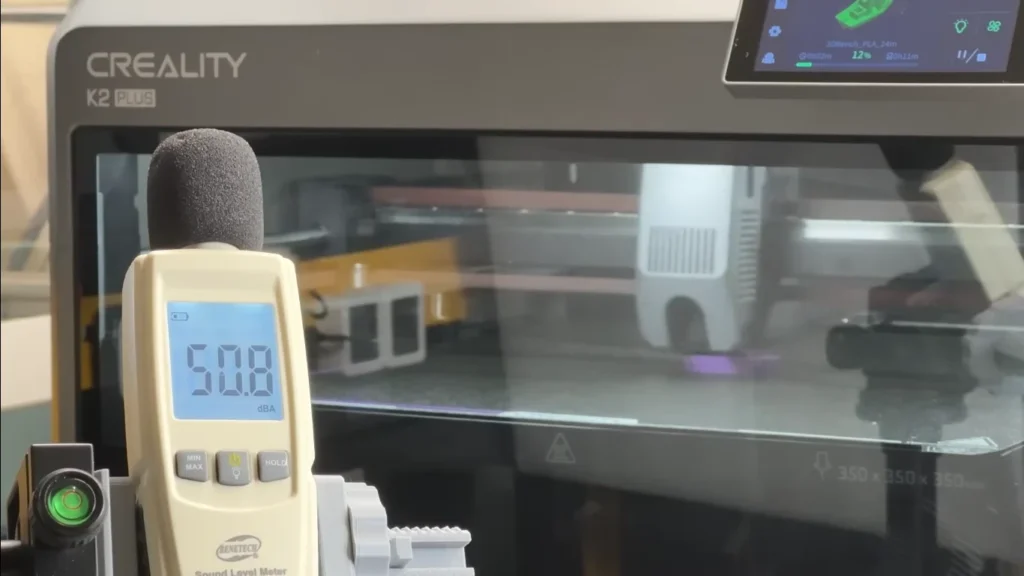

The Bambu Lab P1S operates relatively quietly, especially in enclosed mode. Its well-balanced fans minimize noise during operation, making it suitable for shared workspaces. While not entirely silent, the sound levels are acceptable for most environments.

The Creality K2 Plus takes quiet operation to another level with its FOC step-servo motors and enclosed design. Noise levels remain below 45 dB even during high-speed prints, allowing for distraction-free workflows. For environments sensitive to sound, the K2 Plus is a superior choice.

Winner: Creality K2 Plus – Its quiet operation enhances usability in shared or home settings.

Noise and Environmental Considerations

The K2 Plus operates at a surprisingly low noise level, thanks to its step-servo motors and dynamic fan balance. This makes it suitable for use in quiet environments like offices or homes.

The P1S, while quieter than many entry-level printers, becomes noisier during high-speed operations, primarily due to its cooling fans. Its enclosure does help dampen some sound, but it remains more audible compared to the K2 Plus.

Winner: Creality K2 Plus – Its quieter operation makes it better for noise-sensitive spaces.

Accessibility and Maintenance

The Bambu Lab P1S simplifies maintenance with its modular design and accessible components. Features like semi-automatic belt tensioning and easily replaceable parts make upkeep straightforward. However, users may encounter limitations due to proprietary components.

The Creality K2 Plus integrates several maintenance-friendly features, such as magnetic nozzles for quick swaps and automated filament cutters. Its open-source framework allows for custom upgrades and community-driven modifications, giving users more freedom to optimize their machines. The K2 Plus takes the lead for its adaptability and ease of long-term care.

Winner: Creality K2 Plus – Its ergonomic design and ease of maintenance cater to everyday users.

Connectivity and File Management

The Bambu Lab P1S supports Wi-Fi, Bluetooth, and app-based control, enabling seamless file transfers and remote management. Its cloud-based system is convenient but may cause issues if the internet is unreliable. Local options like SD cards provide an alternative.

The Creality K2 Plus offers a more diverse range of connectivity options, including dual-band Wi-Fi, Ethernet, and USB. Its local storage (32 GB EMMC) ensures faster file retrieval, reducing reliance on external networks. With more robust and versatile connectivity, the K2 Plus stands out.

Winner: Creality K2 Plus – Its versatile connectivity options and local storage provide a more seamless experience.

Energy Efficiency

The Bambu Lab P1S operates with a maximum power consumption of 350 W, making it energy-efficient for a high-performance printer. Its compact size and efficient components ensure minimal impact on electricity bills.

The Creality K2 Plus, despite its larger footprint, incorporates energy-saving technologies like FOC motors and precise thermal management. While it consumes more power due to its capabilities, its efficiency remains impressive given the scale of its operations. For energy-conscious users prioritizing performance, the K2 Plus offers better value.

Winner: Creality K2 Plus – Its balanced energy efficiency and advanced motor technology outperform the P1S for extended operation.

Customer Support and Warranty

Bambu Lab provides responsive customer support and frequent firmware updates, enhancing the user experience. Its one-year warranty covers most components, offering peace of mind for new users.

Creality offers a 12-month hassle-free warranty alongside lifetime support. The company’s global presence ensures comprehensive service, and the active user community provides additional resources. With its robust support system and extensive warranty, Creality edges ahead.

Winner: Creality K2 Plus – Its robust warranty and active user community give it an edge in post-purchase support.

Why Choose Creality K2 Plus or Bambu Lab P1S?

Choose the Creality K2 Plus if you want industrial-grade power and flexibility for large, complex projects. It’s perfect for professionals who need a machine that can handle tough materials and big builds.

Go for the Bambu Lab P1S if you’re looking for a sleek, easy-to-use printer for detailed models or multicolor prints. It’s beginner-friendly, compact, and precise, making it ideal for hobbyists or small-scale professionals.

Final Thoughts

The Creality K2 Plus and the Bambu Lab P1S represent two distinct approaches to high-end 3D printing, each excelling in different areas. The Creality K2 Plus is a powerhouse, designed for professionals and enthusiasts who require versatility, durability, and the ability to print large-scale or high-performance parts. With its massive build volume, robust extruder, and advanced material handling capabilities, it’s the ideal choice for those tackling demanding, complex projects.

The Bambu Lab P1S, on the other hand, offers a more refined and user-friendly experience. Its compact size, intuitive software, and polished design make it an excellent option for hobbyists and professionals focused on detail-oriented prints and multicolor capabilities. While it may lack the material range and scalability of the K2 Plus, its speed, precision, and ease of use are hard to overlook.

Ultimately, the decision comes down to your specific needs. If you prioritize industrial-grade performance and flexibility, the K2 Plus is the way to go. For those seeking a plug-and-play solution with strong multicolor features, the P1S is an exceptional choice. Regardless of your preference, both machines push the boundaries of what’s possible in consumer 3D printing, ensuring you’ll have a reliable and innovative tool at your disposal.

The Creality K2 Plus is better suited for large-scale projects due to its expansive 350x350x350 mm build volume and sturdy “Matrix” frame. It handles batch printing and oversized prototypes with ease, making it ideal for industrial applications.

The P1S supports standard filaments like PLA, PETG, and ABS, but it struggles with reinforced materials like carbon fiber blends unless the extruder and hotend are upgraded. For more robust material handling, the K2 Plus is the superior choice.

Both printers excel in multicolor printing. The K2 Plus can print up to 16 colors using its Creality Filament System, offering scalability and precision. The P1S simplifies multicolor management with its AMS but is limited to fewer colors without additional units.

The Creality K2 Plus is quieter, operating at noise levels of around 45 dB, thanks to its step-servo motors and enclosed design. The P1S, while not excessively loud, produces more noticeable noise due to its cooling fans during high-speed prints.

The P1S is highly beginner-friendly due to its streamlined setup, automated calibration, and intuitive software. It’s designed to work right out of the box with minimal user intervention, making it perfect for newcomers to 3D printing.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.