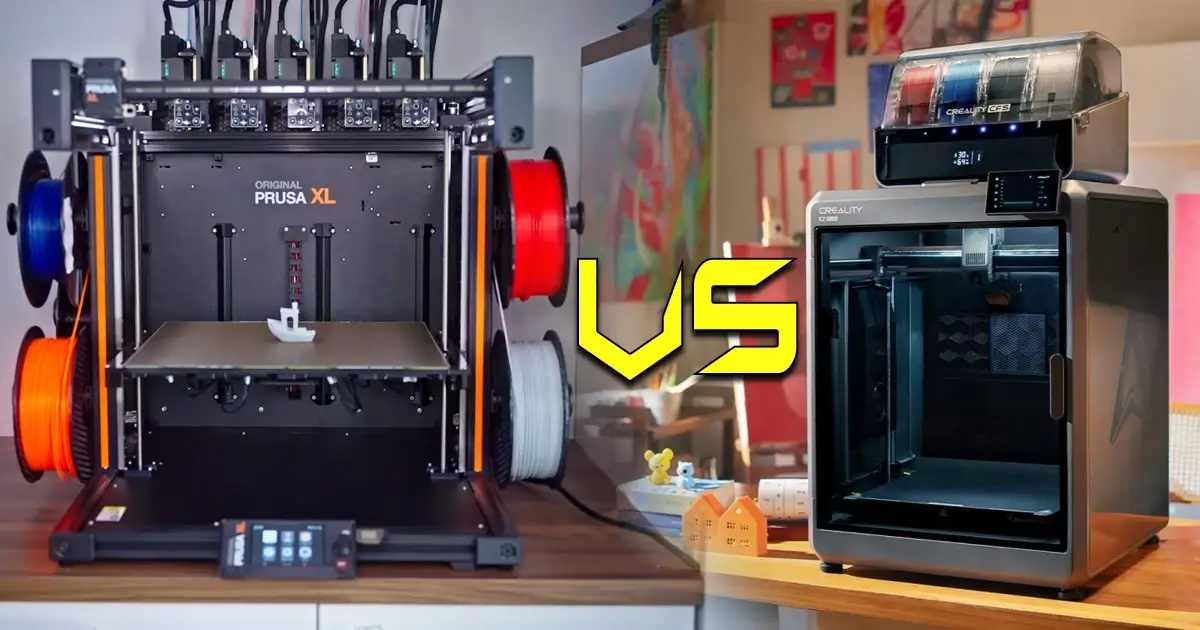

The Creality K2 Plus and Prusa XL have a specific audience, and it’s not the hardcore 3D printing purists who obsess over every millimeter of calibration. These printers are designed for people who want to jump straight into printing without getting lost in the technical weeds.

Setting up either machine might look a bit daunting at first glance — there are tubes, components, and what seems like a million little parts. But here’s the good news: both printers are engineered to make your life easier. The Creality K2 Plus brings high-speed multicolor printing that could have you going from unboxing to first print in less than 10 minutes. The Prusa XL, with its tool-changing wizardry, promises a setup that’s surprisingly intuitive for a machine that looks like it belongs in a high-tech laboratory.

I’ve seen my fair share of 3D printers that require an engineering degree just to get started, but these two break that mold. Whether you’re a complete newbie or someone who wants professional results without the professional headaches, the K2 Plus and Prusa XL are ready to change your game.

First Impressions and Setup Experience

The Creality K2 Plus impresses immediately with its robust, industrial build and thoughtful engineering. Its 350mm cubic build volume is housed within a die-cast aerospace-grade aluminum frame, providing exceptional rigidity. The machine feels sturdy, with dual Z-axis support and precise steel X-axis rails ensuring smooth operation. The printer arrives pre-assembled, and setup is a breeze—requiring little more than attaching the screen and running a quick boot-up guide. Within minutes, the K2 Plus is ready for its first print.

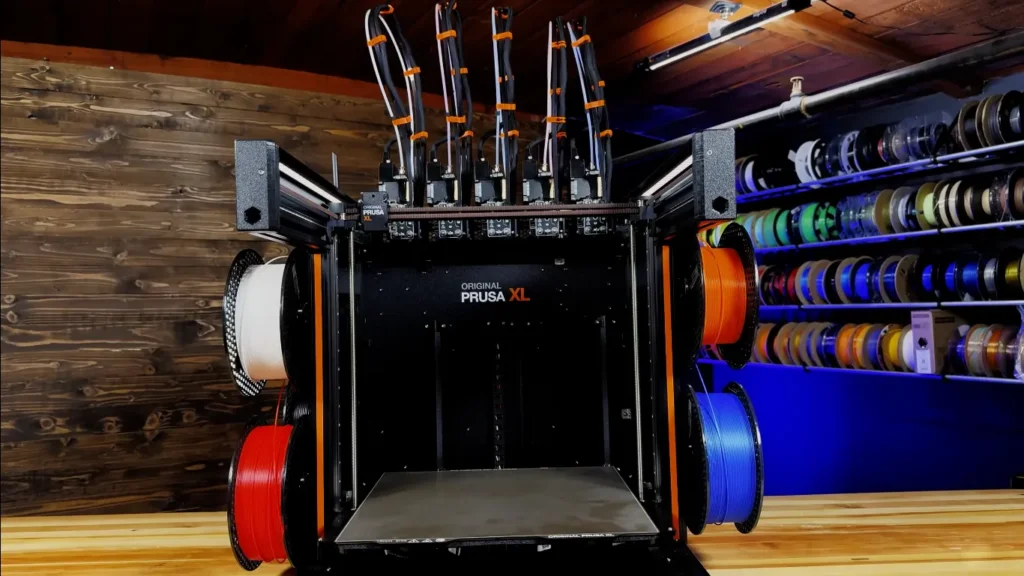

The Prusa XL, on the other hand, carries an aura of refinement and innovation. With its modular design and tool-changing capabilities, it represents a more sophisticated approach to 3D printing. Setting up the semi-assembled model takes a bit longer, as it involves attaching the toolheads and calibrating them. However, Prusa’s detailed guides and calibration processes ensure a seamless experience, even for users new to multi-tool systems. The segmented heatbed and sturdy CoreXY kinematics speak to Prusa’s engineering prowess, instilling confidence in its precision and reliability.

Winner: Creality K2 Plus – The pre-assembled design and user-friendly boot-up guide make it ideal for users who want to start printing immediately without extensive calibration.

Creality K2 Plus vs Prusa XL Specification Chart

| Feature | Creality K2 Plus | Prusa XL |

|---|---|---|

| Launch Date | July 2024 | March 2023 |

| Build Volume | 350 × 350 × 350 mm | 360 × 360 × 360 mm |

| Extruder Type | Direct drive | Nextruder (Direct Drive, Tool-Changing System) |

| Nozzle Temperature | Up to 350°C | Up to 290°C |

| Heatbed Temperature | Up to 120°C | Up to 120°C |

| Chamber Temperature | Actively heated, up to 60°C | None (optional enclosure for temperature-sensitive materials) |

| Multicolor/Multimaterial System | Creality Filament System (CFS), up to 16 colors | Toolchanger, up to 5 materials simultaneously |

| Printing Speed | Up to 600 mm/s | High-speed with Input Shaper and Pressure Advance |

| Supported Filaments | PLA, ABS, PETG, ASA, TPU, Nylon Carbon Fiber, more | PLA, ABS, PETG, TPU, Nylon, PCCF, more |

| Connectivity | Wi-Fi, LAN, USB | Wi-Fi, Ethernet, USB |

| Noise Levels | ≤ 45 dB | 50 dB (typical), low 60s dB during rapid movements |

| Bed Leveling | Full-auto with strain gauge sensor | Full-auto with load cell sensor |

| Modularity | Fixed extruder and system | Modular toolhead design for easy upgrades |

| Firmware Updates | Creality updates with new features | Long-term updates with major improvements |

| Price | Starts at $1,299 | Starts at $1,999 |

Performance and Print Quality

When it comes to print quality, both machines deliver exceptional results but cater to slightly different priorities. The K2 Plus boasts high-speed capabilities with a maximum speed of 600mm/s and an acceleration of 30,000mm/s². Even at such speeds, its prints are remarkably detailed, thanks to its step-servo motor system and advanced cooling fans. The tri-metal nozzle design minimizes clogs, and the actively heated chamber supports high-end materials like ABS and ASA. Test prints revealed sharp details, smooth surfaces, and minimal artifacts, even on complex models.

The Prusa XL, on the other hand, emphasizes precision and versatility. Its Nextruder system, paired with Input Shaper and Pressure Advance technologies, ensures top-notch surface quality even at high speeds. The printer excels in handling overhangs and intricate geometries, producing models with excellent mechanical strength and smooth finishes. Its ability to seamlessly integrate multiple materials within a single print, such as combining flexible TPU with rigid PLA, sets it apart in terms of creative potential.

Winner: Prusa XL – Input Shaper and Pressure Advance technologies deliver exceptional print precision, particularly for intricate or multicolor designs.

Material Compatibility and Multicolor Printing

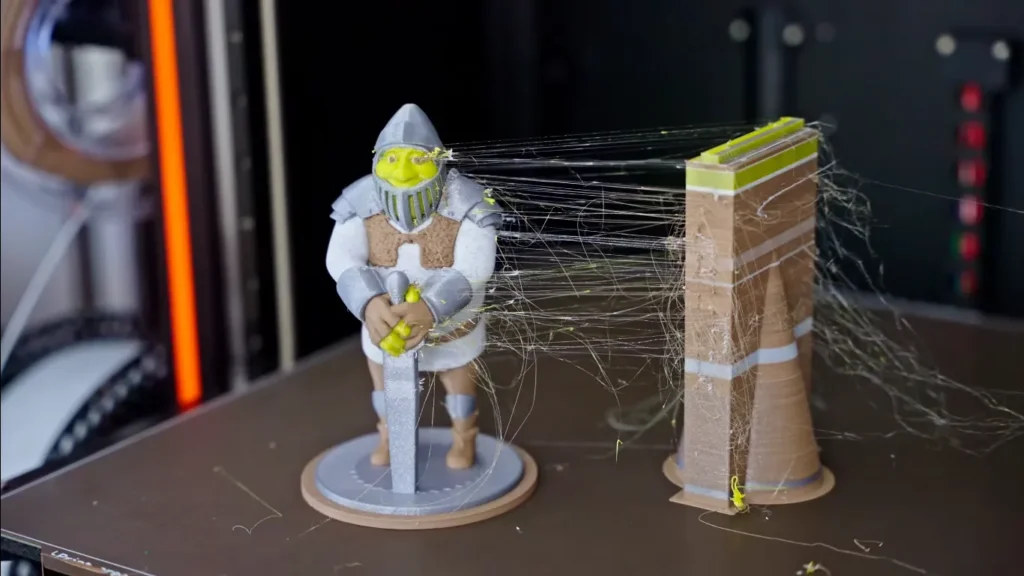

The K2 Plus and Prusa XL are both masters of material versatility, but they achieve this in different ways. The K2 Plus’s actively heated chamber and high-temp nozzle make it suitable for a wide range of engineering materials, including nylon carbon fiber and ASA. Its CFS system, though impressive in its ability to manage 16 colors, still generates some filament waste during color changes—a common limitation of single-nozzle multicolor systems.

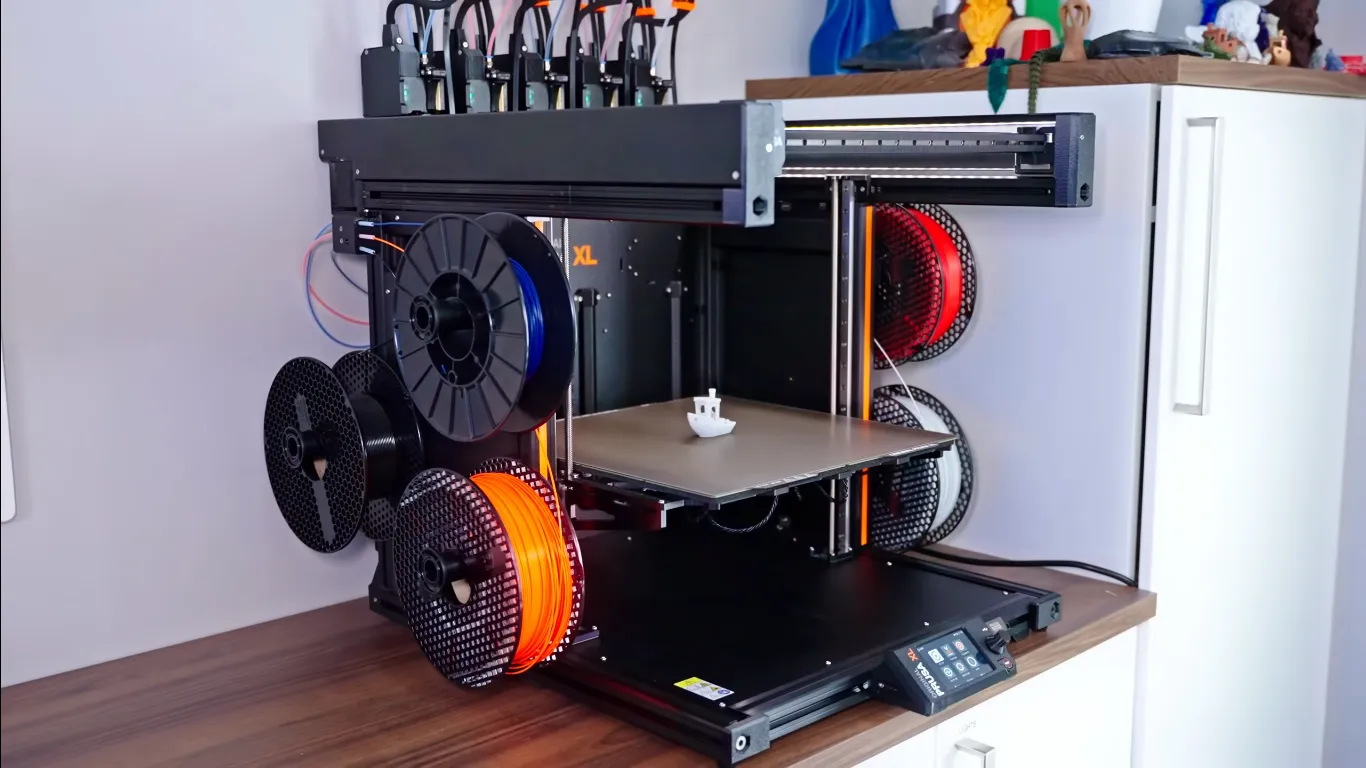

The Prusa XL addresses this challenge with its tool-changing mechanism, which drastically reduces material waste. By using individual toolheads for different filaments, the XL eliminates the need for extensive purging. This efficiency is particularly beneficial for projects requiring expensive materials or detailed multicolor designs. The XL also supports a broader range of technical materials, with the option to add an enclosure for temperature-sensitive filaments.

Winner: Prusa XL – The tool-changing system minimizes waste and enhances flexibility, making it a superior choice for diverse material and multicolor printing needs.

Thermal Management and Material Optimization

Thermal management is crucial for consistent print quality, especially when working with advanced filaments. The Creality K2 Plus boasts an actively heated chamber that can reach 60°C, essential for materials like ABS and ASA. Dual cooling fans within the chamber and an 80W high-flow hotend ensure even heat distribution and minimize warping. However, it struggles slightly with materials like TPU in its multi-filament setup, limiting its versatility for flexible filaments.

The Prusa XL offers a segmented heatbed with 16 independently controlled zones, allowing precise temperature management and reduced energy consumption for smaller prints. While the lack of an enclosed chamber may limit its ability to handle temperature-sensitive materials like ASA, the XL compensates with its Nextruder’s exceptional thermal efficiency and ability to handle a variety of materials, including flexible filaments, with ease.

Winner: Prusa XL – The segmented heatbed and thermal efficiency of the Nextruder provide better overall material optimization, though the K2 Plus offers a competitive heated chamber.

Build Volume and Flexibility

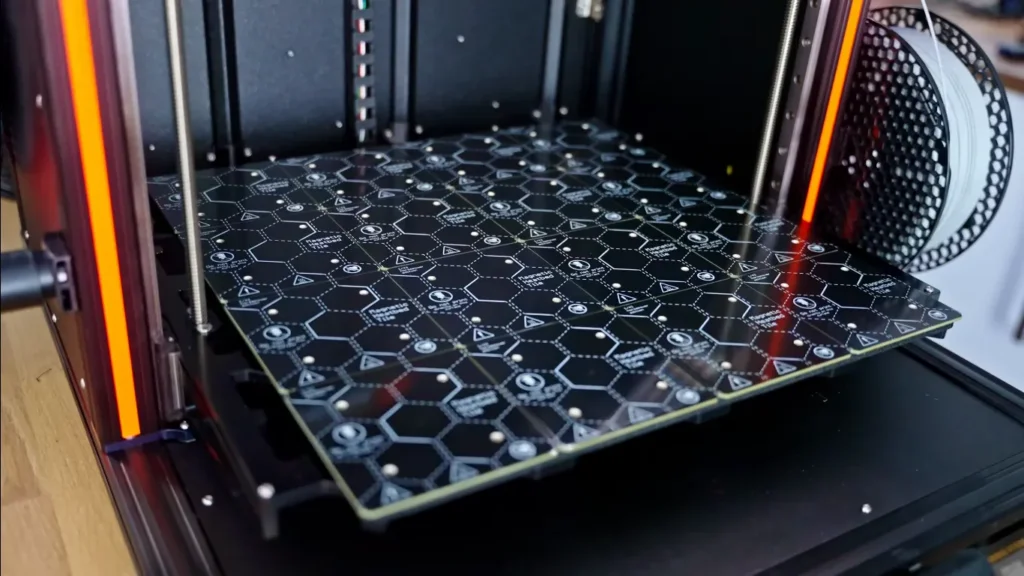

Both printers offer substantial build volumes that cater to ambitious projects. The K2 Plus provides a 350x350x350mm build area, which is well-suited for large-scale models or batch printing. Its flexible build plate and sturdy frame ensure consistent performance across the entire print area.

The Prusa XL takes it a notch higher with its slightly larger 360x360x360mm build volume. The segmented heatbed, which heats only the areas in use, is a thoughtful addition that improves energy efficiency. The modular design allows users to start with a single-tool setup and gradually expand to five toolheads, providing unmatched flexibility for future needs.

Winner: Prusa XL – The segmented heatbed and modular toolhead design provide greater flexibility for diverse printing needs, giving it the edge.

Usability and Workflow

The Creality K2 Plus places significant emphasis on usability, particularly with its Creality Filament System (CFS). This multicolor system supports up to 16 colors through chained CFS units, making it a game-changer for creative projects. The machine’s smart features, such as automatic filament cutting and run-out detection, simplify the user experience. The dual AI cameras for monitoring and real-time error detection add another layer of convenience, especially for long or complex prints.

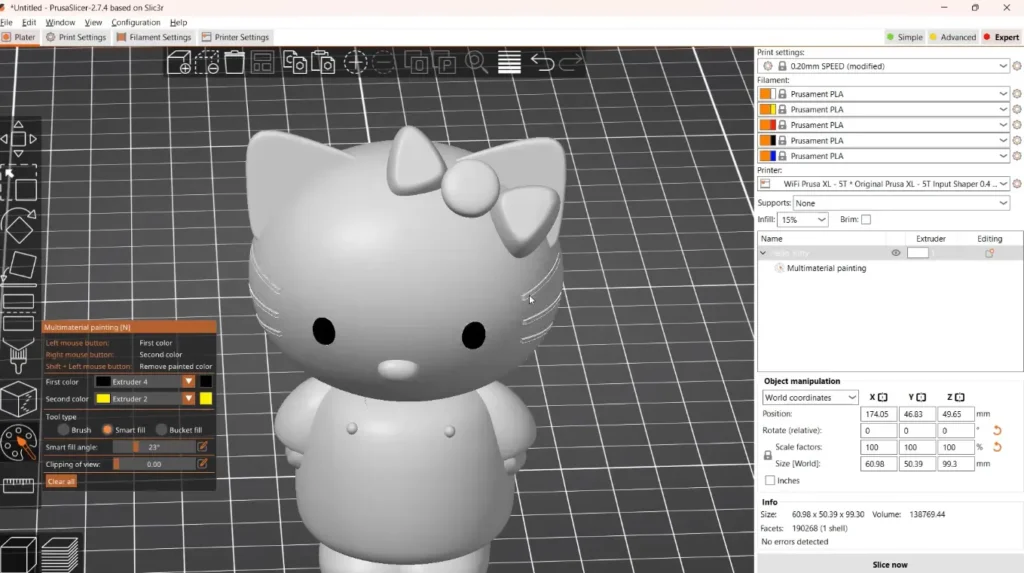

Prusa XL takes usability a step further with its advanced tool-changing system. Swapping between up to five toolheads is nearly instantaneous, enabling true multimaterial and multicolor printing without the need for extensive filament purging. The printer’s auto-bed leveling, guided calibration, and segmented heatbed allow for unparalleled ease of use. Features like Spool Join, which automatically switches to a new spool mid-print, further enhance its practicality, especially for large-scale or intricate projects.

Winner: Prusa XL – Advanced features like the tool-changing system, Spool Join, and wipe-to-infill ensure superior ease of use for professional-level projects.

Software Ecosystem and Workflow Integration

The software ecosystem behind a 3D printer can make or break the user experience, particularly for those managing complex projects. The Creality K2 Plus comes equipped with Creality Print 5.0, a slicer that has been revamped for efficiency and precision. It offers over 40 filament presets and multicolor slicing capabilities, integrating well with Creality’s Cloud ecosystem. The mobile app and LAN connectivity ensure seamless operation, making it highly accessible for users managing multiple machines or remote monitoring. However, Creality’s ecosystem remains somewhat proprietary, with certain features requiring Creality-specific filaments or setups for optimal performance.

In contrast, the Prusa XL takes a more open and community-focused approach. It supports open-source software, including PrusaSlicer, which has been praised for its advanced features like wipe-to-infill and detailed multi-material management. The inclusion of Prusa Connect adds robust cloud-based functionality for print scheduling and monitoring, making it ideal for professionals juggling multiple projects. The system’s open-source nature ensures compatibility with third-party filaments and accessories, giving it a distinct edge.

Winner: Prusa XL – The openness, advanced features, and seamless integration with third-party solutions make it the clear choice for those prioritizing software flexibility.

Noise and Environmental Impact

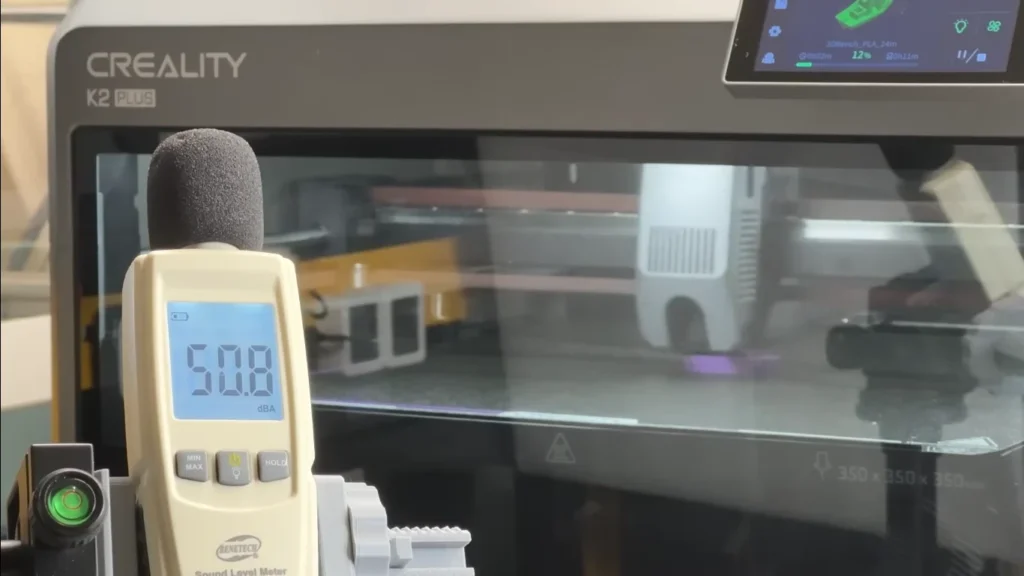

Noise levels are a significant consideration for users in shared or home environments. The Creality K2 Plus operates at an exceptionally quiet 45 dB, made possible by its step-servo motors, dynamically balanced fans, and enclosed design. This low noise level makes it comfortable to use in close quarters without disrupting your surroundings. Additionally, the built-in air purifier enhances environmental friendliness by filtering out VOCs generated by molten filaments, further cementing its suitability for extended print sessions in domestic spaces.

The Prusa XL, though slightly louder, remains impressively quiet for a machine of its size and complexity. With Phase Stepping technology, it maintains sound levels around 50 dB during typical operation, occasionally rising to the low 60s during rapid movements. This is still within a tolerable range, especially for professional environments. Its energy-efficient segmented heatbed and zero-waste multicolor printing capabilities align with sustainability goals, offering an eco-conscious printing solution for long-term use.

Winner: Creality K2 Plus – With quieter operation and a built-in air purifier, it edges out the Prusa XL for users prioritizing noise reduction and environmental comfort.

Maintenance and Durability

Both machines are designed to endure the rigors of frequent, demanding use, but their approaches to maintenance differ. The Creality K2 Plus benefits from its step-servo motors and advanced sensors, which help identify and prevent mechanical issues like belt tension loss. Its hardened steel gears and tri-metal nozzle offer durability, making it capable of withstanding the repeated use of abrasive materials. However, its reliance on proprietary components like the Creality Filament System may make replacements or upgrades more expensive or harder to source.

The Prusa XL, on the other hand, adopts a modular design that simplifies repairs and upgrades. Its segmented heatbed is not only energy-efficient but also easy to replace if needed. Prusa’s support for firmware updates years after a printer’s release is another plus, ensuring that the XL remains future-proof. Maintenance tasks like nozzle swaps and filament changes are straightforward, reflecting Prusa’s emphasis on user experience.

Winner: Prusa XL – Its modular design, ease of maintenance, and long-term firmware support make it better suited for sustained professional use.

Price and Value Proposition

The Creality K2 Plus starts at $1,299 for the base model, with options to add CFS units for multicolor printing. This pricing positions it as a high-value option for users seeking professional-grade features without breaking the bank. Its robust build, advanced features, and impressive performance make it a solid investment for hobbyists and professionals alike.

The Prusa XL, on the other hand, comes with a steeper price tag, starting at $1,999 for the semi-assembled single-toolhead model and reaching $4,000 for the fully assembled five-toolhead version. While the upfront cost is high, the XL’s unique capabilities, such as its tool-changing system and near-zero material waste, justify the investment for users with demanding multicolor or multimaterial printing needs.

Winner: Creality K2 Plus – Competitive pricing and a robust feature set provide professional-grade performance at a significantly lower cost, making it an excellent option for budget-conscious users.

Limitations and Considerations

No machine is without its drawbacks, and these two are no exception. The K2 Plus, while excellent in many aspects, requires careful handling of its multicolor system to minimize filament waste. Its reliance on proprietary features like the CFS may also limit compatibility with third-party solutions.

The Prusa XL’s primary limitation is its high price, which may deter casual users. Additionally, its tool-changing system, while innovative, adds a layer of complexity that requires a steeper learning curve. Maintenance, such as lubricating moving parts and calibrating toolheads, is essential to ensure consistent performance.

Longer-Term Testing and Reliability

The Creality K2 Plus, launched in July 2024, demonstrated strong reliability during prolonged use, with its step-servo motors delivering consistent performance even during demanding, high-speed prints. Features like active belt tensioning and the heated chamber ensured stability with materials like ASA and nylon carbon fiber. However, its Creality Filament System (CFS) occasionally required recalibration during frequent color changes, and TPU handling remained inconsistent in multicolor setups, adding slight maintenance overhead for certain projects.

The Prusa XL, by contrast, excelled with its modular design and segmented heatbed, which reduced strain and extended component lifespan. The tool-changing system performed flawlessly over time, while Prusa’s regular firmware updates introduced improvements like input shaping and advanced calibration, ensuring the printer stayed at the cutting edge. Its reduced maintenance demands and adaptability further reinforced its suitability for professional, long-term use.

Winner: Prusa XL – Its modular build, software enhancements, and lower maintenance needs make it the more reliable choice for sustained performance.

User Community and Support

The role of a strong community and reliable customer support cannot be understated in 3D printing. The Creality K2 Plus benefits from Creality’s active online presence and a large base of users who share tips, models, and troubleshooting advice. Creality also offers a 12-month warranty and lifetime support, making it a dependable choice for new users. Its ecosystem is, well, strong — but lacks the depth of community-driven innovations that open-source platforms inspire.

In contrast, the Prusa XL thrives on its open-source philosophy. The Prusa community is famous for its collaborative approach, with reams of user-generated profiles, mods and support forums. Highlighting Prusa’s professional-grade support team, the company also publishes long-term updates to ensure users get the most out of their investment.

Winner: Prusa XL – The combination of a vibrant open-source community and dedicated professional support gives it the edge.

Final Verdict

After putting these machines through their paces, I can tell you they’re not just another pair of 3D printers. The Creality K2 Plus is the workhorse you didn’t know you needed — robust, fast, and surprisingly wallet-friendly. I printed dozens of models, and each one looked excellent, with even layer lines and sharp details that’ll make you want to show off every single print.

Meanwhile, the Prusa XL is like that Swiss Army knife of 3D printing. Its tool-changing system isn’t a gimmick, it’s a true gamechanger for anyone who wants to do things previously thought impossible. Where the K2 Plus gives you speed and affordability, the XL offers precision and potential that’ll make tech enthusiasts weak in the knees.

Your decision ultimately depends on what’s most important to you. Do you require a printer that’ll do the job without trashing your bank account? The K2 Plus has your back. Dreaming of a printer that feels like it’s from the future? The Prusa XL is calling your name. Either way, you’re looking at machines that prove 3D printing isn’t just a hobby anymore — it’s becoming as commonplace as your home inkjet, just a whole lot cooler.

The Creality K2 Plus is more beginner-friendly due to its out-of-the-box usability, pre-assembled design, and straightforward setup process. It’s ideal for users looking to start printing immediately without learning advanced systems. The Prusa XL, while feature-rich, requires more technical knowledge, especially for managing toolheads and calibration.

The Creality K2 Plus uses the Creality Filament System (CFS), which can handle up to 16 colors but requires occasional recalibration and generates some filament waste. The Prusa XL offers a tool-changing system, allowing up to 5 materials with minimal waste. For precision and efficiency in multicolor prints, the Prusa XL has the advantage.

The Creality K2 Plus operates at an exceptionally quiet level of ≤45 dB, even during high-speed prints, making it one of the quietest options for shared or home environments. The Prusa XL, while slightly louder, maintains a noise level of around 50 dB during standard operation, occasionally reaching the low 60s during rapid movements. While both are relatively quiet, the K2 Plus has a noticeable edge in noise reduction for quieter spaces.

Yes, both printers can print with flexible filaments, but their performance varies. The Prusa XL handles TPU with greater consistency due to its advanced Nextruder design. The K2 Plus is compatible with TPU, but it performs better when not using the multi-filament setup.

The Creality K2 Plus provides excellent value, offering high-speed performance, multicolor capabilities, and a large build volume at a lower price point. The Prusa XL, while more expensive, justifies its cost with superior precision, modularity, and long-term firmware support, making it a worthwhile investment for professionals.

Nestor Sawayn is a U.S.-based tech journalist specializing in maker tools and creative technologies. His coverage spans 3D printers, vinyl cutters, paper printers, and laser cutters across North America, Europe, and Asia. Sawen’s articles offer concise, insightful analysis of the latest News, innovations in this space. Beyond hardware, he explores the creative potential of board games and tabletop RPGs, providing readers with a comprehensive view of both digital and analog maker trends.

Feel free to reach out to me at nestorsawayn@360techinsights.com.