The Formlabs Form 4, released in 2024, is a high-speed resin 3D printer featuring MSLA technology and a Low Force Display™ engine. It offers exceptional precision with 50-micron resolution, rapid printing at up to 100 mm/hour, and compatibility with numerous materials. While it provides superior quality and speed for professional use, its premium price (starting at $4,499) may be prohibitive for hobbyists.

Introduction

With 3D printing constantly pushing boundaries, speed and efficiency reign supreme. Enter the Formlabs Form 4, a resin printer promising lightning-fast turnaround times – churning out most parts in under two hours! Formlabs blasts onto the scene with the Form 4, aiming to rewrite the rules of speed, precision, and reliability. This in depth review will expose everything about this cutting edge machine, revealing its strengths, weaknesses & whether it truly lives up to the hype.

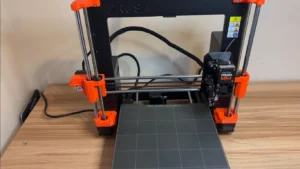

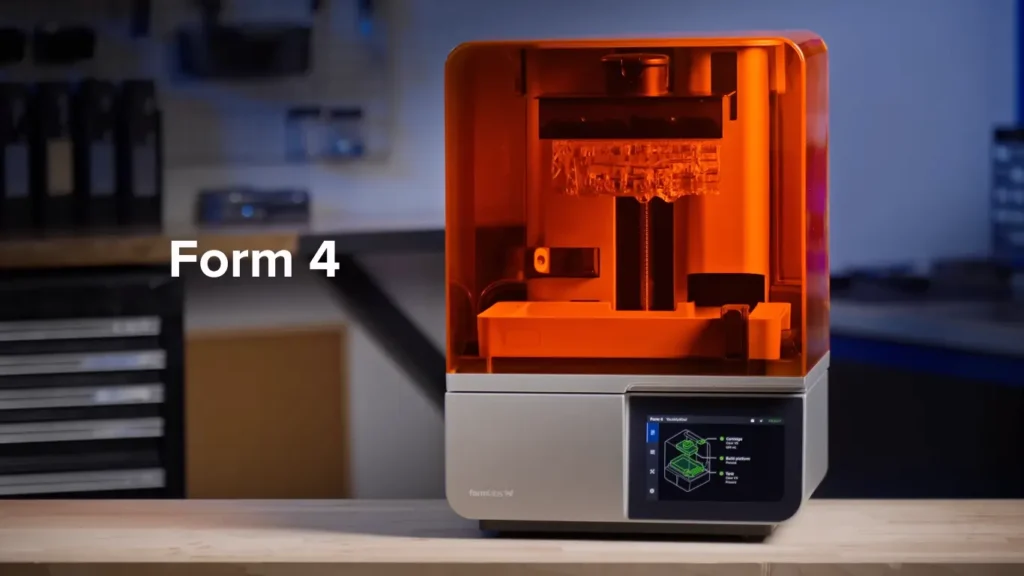

Design and Build Quality

Sleek and Sturdy Aesthetics

Right out of the box, the Formlabs Form 4 exudes a sense of quality and durability. Right out of the box, the Formlabs Form 4 exudes a sense of quality and durability. The Form 4’s industrial design is all business: clean lines, tough build, and high-quality materials that shout durability. It’s clear this machine is built to work hard & look good doing it.

User-Friendly Interface

One of the standout features of the Formlabs Form 4 is its user-friendly interface. The 7-inch interactive touchscreen, with its intuitive layout and clear icons, makes navigating the printer’s settings & functions a breeze. Even for those new to resin 3D printing, the interface is remarkably easy to grasp, minimizing the learning curve.

Print Quality and Accuracy

Unparalleled Detail and Precision

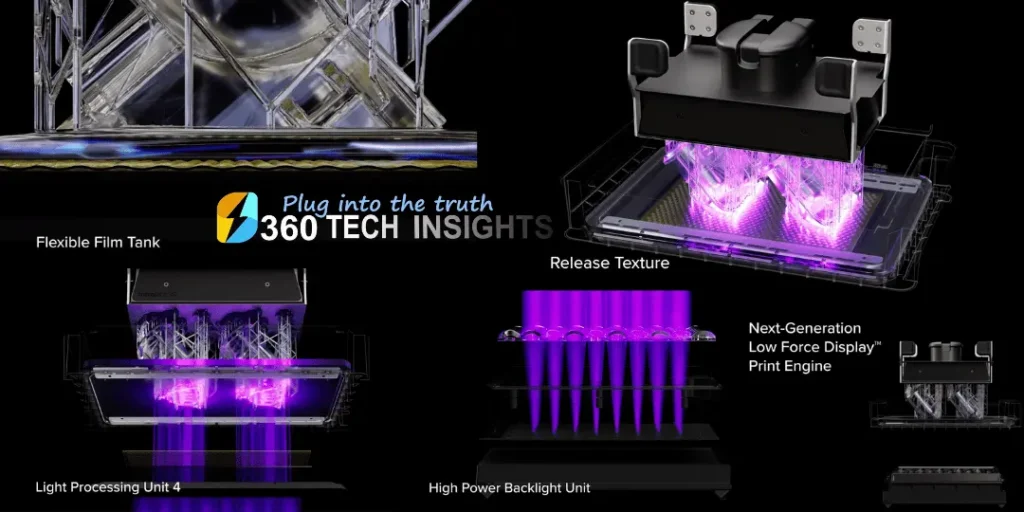

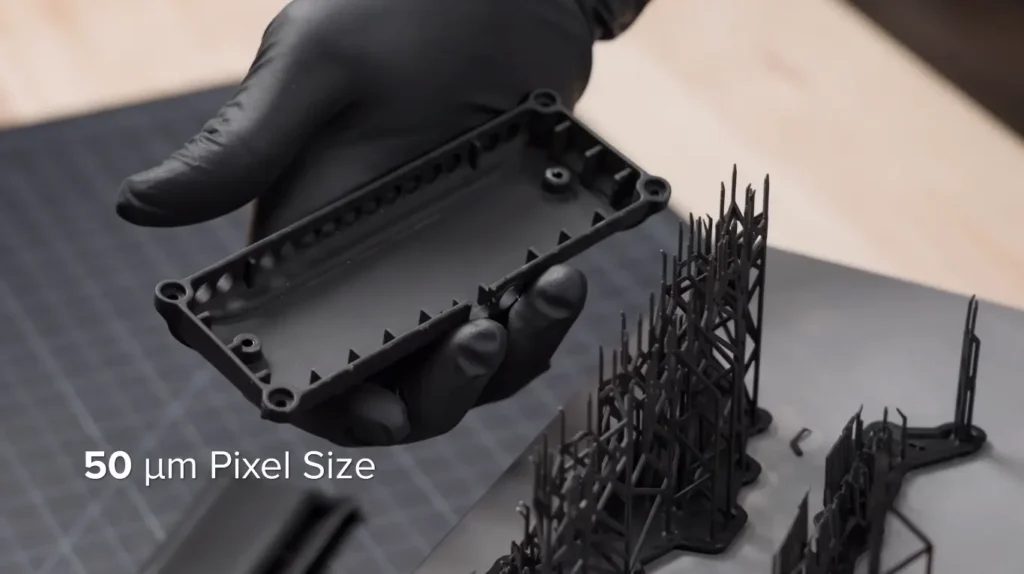

When it comes to print quality, the Formlabs Form 4 sets a new bar for resin 3D printers. Thanks to its advanced Light Processing Unit 4 (LPU 4) and 50-micron pixels, the printer delivers exceptional detail & precision. The resulting prints boast crisp, well-defined edges & perfectly smooth surfaces, rivaling the quality of injection-molded parts.

Consistent Tolerances

One of the key advantages of the Formlabs Form 4 is its ability to maintain consistent tolerances across various materials and print sizes. With superior and repeatable tolerances, parts printed on the Form 4 match design parameters with remarkable accuracy, ensuring seamless assembly and integration into existing workflows.

Speed and Efficiency

Lightning-Fast Print Times

The Formlabs Form 4 lives up to its promise of unprecedented speed. Powered by the Low Force Display™ print engine, this printer can achieve print speeds of up to 100 mm per hour, outpacing many of its competitors. In real-world testing, we witnessed print times two to four times faster than previous Formlabs models, significantly reducing turnaround times and enabling multiple design iterations per day.

Streamlined Workflow

Formlabs has designed the Formlabs Form 4 with efficiency in mind. From the automatic resin handling features that minimize downtime to the Quick Release Technology for easy part removal, every aspect of the workflow has been optimized for seamless operation. The printer’s comprehensive software suite, including PreForm & Dashboard, further enhances productivity by automating tasks and providing remote monitoring capabilities.

Material Versatility

Expansive Materials Library

One of the standout strengths of the Formlabs ecosystem is its extensive materials library. With over 23 industry-leading resins available for the Form 4, including true silicone, technical ceramic & polyurethane, the printer opens up a world of possibilities for various applications and industries. From engineering and product design to healthcare & manufacturing, the diverse material offerings cater to a wide range of needs.

Open Platform Flexibility

While Formlabs offers an impressive selection of proprietary resins, the Form 4 also supports an Open Platform approach. This feature allows users to experiment with third-party materials, providing even greater flexibility & customization options. No matter what you’re after, unique materials or fresh ideas, the Open Platform lets you break new ground in 3D printing.boundaries of 3D printing.

Reliability and Consistency

Rigorous Quality Control

Formlabs takes reliability seriously, and the Form 4 is no exception. The Form 4 isn’t built on a whim. Each printer endures a rigorous 60-point functionality check before leaving the factory. This meticulous quality control ensures consistent performance & minimizes hiccups, making the Form 4 a reliable workhorse even for demanding, high volume jobs.

Intelligent Sensor System

The Form 4 is equipped with an advanced sensor system that monitors various aspects of the printing process. This intelligent system can detect and alert users to potential issues, allowing for timely intervention & minimizing the risk of print failures. With real-time monitoring and alerts, users can rest assured that their prints are in good hands.

Ecosystem and Support

Comprehensive Software Suite

Formlabs offers a comprehensive software suite that complements the Form 4 printer. PreForm, the print preparation software, streamlines the process with features like automatic orientation, support generation & material-specific settings. Additionally, the Dashboard application provides remote monitoring capabilities, enabling users to track print progress and receive alerts from anywhere.

Extensive Documentation and Support

Formlabs understands the importance of user support and has invested in creating extensive documentation & resources. From detailed user manuals to online tutorials and a knowledgeable support team, users can easily access the guidance they need to get the most out of their Form 4 printer.

Drawbacks and Limitations

Premium Pricing

Despite its impressive capabilities, the Formlabs Form 4 comes with a premium price tag. At $4,499 for the Basic Package and up to $8,699 for the Premium Package, this printer is undoubtedly a significant investment. While the cost may be justifiable for businesses and professionals who rely on 3D printing for their workflows, it could be prohibitive for hobbyists and those on a tighter budget.

Limited Build Volume

While the Form 4 offers a larger build volume compared to its predecessors, with a maximum part length of 27.3 cm (10.7 inches), it may still fall short for certain applications that require larger parts or assemblies. Users working on projects that exceed the build volume may need to consider alternative solutions or break down their designs into smaller components.

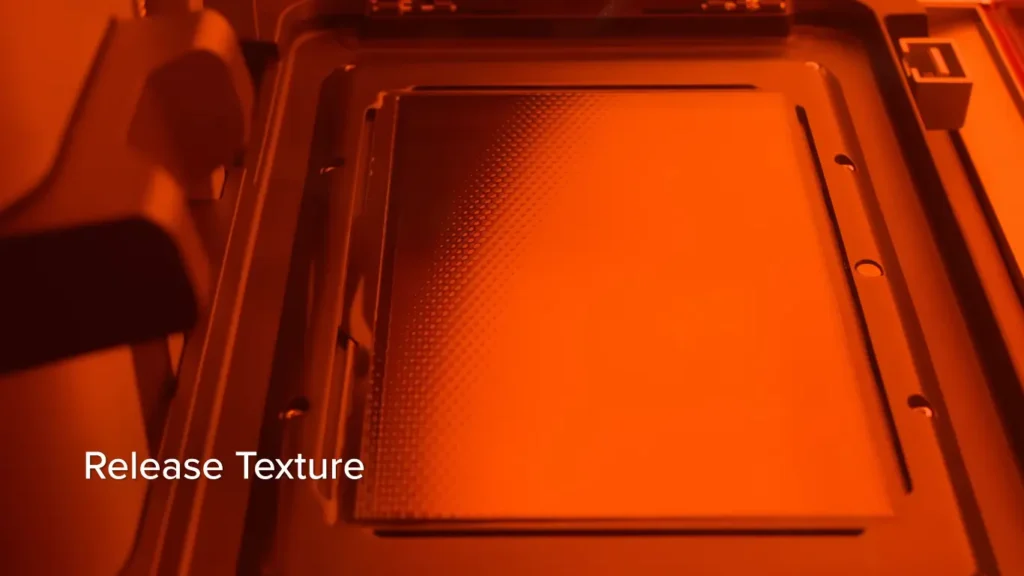

Breaking Down the Speed

- Rapid Resin Curing with LED Backlight

- The Form 4’s Low Force Display™ print engine combines high-power LEDs and masking lenses for instantaneous layer curing.

- Curing speeds are unaffected by part size or quantity, enabling batch printing without extending print times.

- Superior Resin Handling and Delivery

- Automatic resin dispensing and heating maximize uptime, reducing changeover time between prints.

- Smart sensors monitor resin levels and temperature for optimal delivery and consistent results.

Dimensional Precision Redefined

- Micron-Level Tolerances

- The 50-micron XY resolution and advanced pixel smoothing ensure tight and repeatable tolerances across all materials.

- Multi-part assemblies fit seamlessly, and surfaces match the smoothness of injection-molded plastics.

- Consistent Part Quality Through Production Cycles

- With repeatable tolerances matching initial designs, part appearance and performance remain consistent from prototyping to final production.

User-Friendly Workflow Innovations

- Quick-Start Printing

- Streamlined setup process allows users to start their first print within 15 minutes, regardless of experience level.

- Automated Post-Processing

- The integrated Form Wash and Form Cure systems ensure consistent and efficient post-processing, reducing manual labor.

- Remote Monitoring and Control

- The PreForm software and Dashboard application enable remote print monitoring, progress tracking, and alert management.

Unrivaled Ecosystem Support

- Comprehensive Materials Library

- Formlabs’ continuously expanding library of over 23 resins caters to diverse applications across industries.

- New materials with advanced properties like high viscosity and filled resins are now possible with the Form 4’s upgraded handling capabilities.

- Open Platform Customization

- Users can opt for Open Platform mode, enabling compatibility with certified third-party materials and customizable print settings.

- Dedicated Customer Support and Resources

- Extensive documentation, online tutorials, and a knowledgeable support team ensure users can access guidance whenever needed.

Formlabs Form 4 Resin 3D Printer Pros & Cons

Pros

- Blazing-fast print speeds: The Formlabs Form 4 truly shines when it comes to speed, with the ability to print most parts in under two hours. This remarkable print speed is achieved through the advanced Low Force Display™ print engine, enabling users to iterate designs multiple times per day, Significantly Accelerating Workflows.

- Unmatched accuracy and precision: With its 50-micron pixels, advanced pixel smoothing, and light-touch support system, the Form 4 delivers exceptional dimensional accuracy and surface finish. Parts printed on this printer rival the Quality of Injection-molded components, ensuring seamless integration into existing processes.

- Expansive materials library: Formlabs offers a diverse range of over 23 industry-leading resins, including specialized materials like true silicone, technical ceramic, and polyurethane. Many opportunities for diverse applications across industries are made possible by this vast materials catalog.

- Robust reliability and consistency: The Form 4 prioritizes reliability through rigorous quality control measures and an intelligent sensor system that monitors the printing process. This commitment to consistency ensures minimal print failures & downtime, even in high-volume production environments.

- Comprehensive software ecosystem: Formlabs provides a user-friendly software suite, including PreForm for print preparation and Dashboard for remote monitoring. This integrated ecosystem streamlines the entire workflow, enhancing productivity and ease of use.

Cons

- Premium pricing: The Formlabs Form 4 comes with a premium price tag, with the Basic Package starting at $4,499 and the Premium Package reaching $8,699. This high cost may be a barrier for hobbyists, small businesses & those with limited budgets.

- Limited build volume: While the Form 4 offers a larger build volume compared to previous models, its maximum part length of 27.3 cm (10.7 inches) may still be restrictive for certain applications that require larger parts or assemblies.

- Steep learning curve for new users: While Formlabs has made efforts to simplify the user experience, the Form 4 may still present a learning curve for those new to professional-grade 3D printing and the Formlabs ecosystem.

- Proprietary materials and consumables: While the Open Platform feature allows for third-party material compatibility, Formlabs’ proprietary resins and consumables can be expensive, potentially increasing operational costs for users.

- Limited portability: Due to its size and weight, the Form 4 may not be the most portable option for those requiring frequent relocation or on-site printing capabilities.

Conclusion

In the realm of conjuring physical forms from digital phantoms, the Formlabs Form 4 Resin 3D Printer stands as a marvel. Its speed surpasses the nimblest pixies, its accuracy rivals the most seasoned sculptor of dreams, and its material adaptability would astound an alchemist. While its cost may cause some to pause and its capacity may seem finite to the overambitious, its unwavering reliability and masterful performance solidify it as a legend whispered among designers, engineers, and those who weave the future into reality.

Formlabs has woven a sigil of dedication to progress & user intuition, birthing a printer that not only fulfills the desires of its chosen, but transcends them. From birthing intricate prototypes to coaxing final forms from the digital void, or even pushing the boundaries of this sorcerous craft itself, the Formlabs Form 4 Resin 3D Printer is an instrument imbued with power. It calls forth Imagination, the obedient friend who elevates Human Brilliance to new heights.

Table of Specifications

| Specification | Value |

|---|---|

| Technology | Masked Stereolithography (MSLA) |

| Light Source | 405 nm wavelength, 16 mW/cm² optical power intensity |

| Maximum Print Speed | 100 mm/hour |

| Typical Print Speed | 15-100 mm/hour depending on material |

| XY Resolution | 50 µm with pretuned anti-aliasing |

| Layer Thickness | 25-300 µm |

| Build Volume | 20.0 x 12.5 x 21.0 cm (7. |

My Opinion: Will it be profitable for you?

The profitability of investing in the Formlabs Form 4 Resin 3D Printer largely depends on your specific business needs, application requirements, and potential return on investment (ROI). While the premium pricing may seem steep, the printer’s unparalleled speed, accuracy & material versatility can potentially translate into significant productivity gains and cost savings in the long run.

If your business relies heavily on rapid prototyping, iterative design processes or the production of high-precision parts & components, the Form 4 could be a game-changer. The ability to achieve multiple design iterations per day & quickly validate concepts could accelerate time to market and provide a competitive edge. Additionally, the printer’s compatibility with specialized materials like silicone, ceramics & polyurethane opens up new revenue streams & business opportunities.

However, for hobbyists, small businesses or those with limited budgets, the Form 4 may not be the most cost effective option. In such cases, exploring more affordable alternatives or considering entry-level professional printers might be a wiser choice initially. Ultimately, a thorough cost-benefit analysis, considering your specific needs and projected ROI, will determine whether investing in the Formlabs Form 4 Resin 3D Printer is a profitable venture for your business or endeavor.

:Frequently Asked Questions:

What is the maximum build volume of the Formlabs Form 4?

The Formlabs Form 4 has a build volume of 20.0 x 12.5 x 21.0 cm (7.9 x 4.9 x 8.3 inches), with a maximum part length of 27.3 cm (10.7 inches). While larger than previous models, it may still be limiting for certain applications requiring larger parts or assemblies.

How long does the Light Processing Unit (LPU) last?

Formlabs estimates the LPU’s lifespan to be between 600,000 and 1,900,000 layers, depending on the material & layer height used. This translates to approximately 2,800 prints using average-height models (39 mm tall), Grey Resin V5, and a 100µm layer height.

Is the Formlabs Form 4 compatible with third-party materials?

Yes, the Form 4 supports an Open Platform feature, allowing users to experiment with certified third-party materials and customize print settings accordingly. Beyond the range of proprietary resins offered by Formlabs, this offers flexibility.

What software is included with the Formlabs Form 4?

The Form 4 comes with PreForm, a print preparation software for setting up prints, and Dashboard, a remote monitoring application for tracking print progress and receiving alerts. Both enhance the overall user experience & workflow.

How does the Formlabs Form 4 handle print failures or potential issues?

The Form 4 features an intelligent sensor system that monitors the printing process & alerts users to potential issues in real-time. This allows for timely intervention and minimizes the risk of print failures, ensuring reliable & consistent results.

What is the Form 4?

The Form 4 is Formlabs’ newest 3D printer that utilizes new technologies like masked stereolithography (MSLA) and a low-force display (LFD) print engine to enable faster and more accurate 3D printing compared to their previous printers.

Is Form 4 mandatory?

No, the Form 4 is not mandatory. It represents the next generation of Formlabs’ 3D printing technology, but is an optional product offering.

What does a Form 4 do?

The Form 4 enables faster 3D printing speeds by using masked stereolithography to cure entire layers at once instead of point-by-point like previous printers. It also provides improved accuracy and surface finish quality compared to prior Formlabs printers by utilizing technologies like the LFD print engine and high resolution LCD masking. However, specific details on its functionality were not provided in this conversation.

What is the build volume of the Form 4?

The Form 4 has a build volume of 20.0 x 12.5 x 21.0 cm (7.9 x 4.9 x 8.3 inches).

Does the Form 4 support third-party materials?

Yes, the Form-4 has an Open Platform feature that allows the use of certified third-party materials.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.