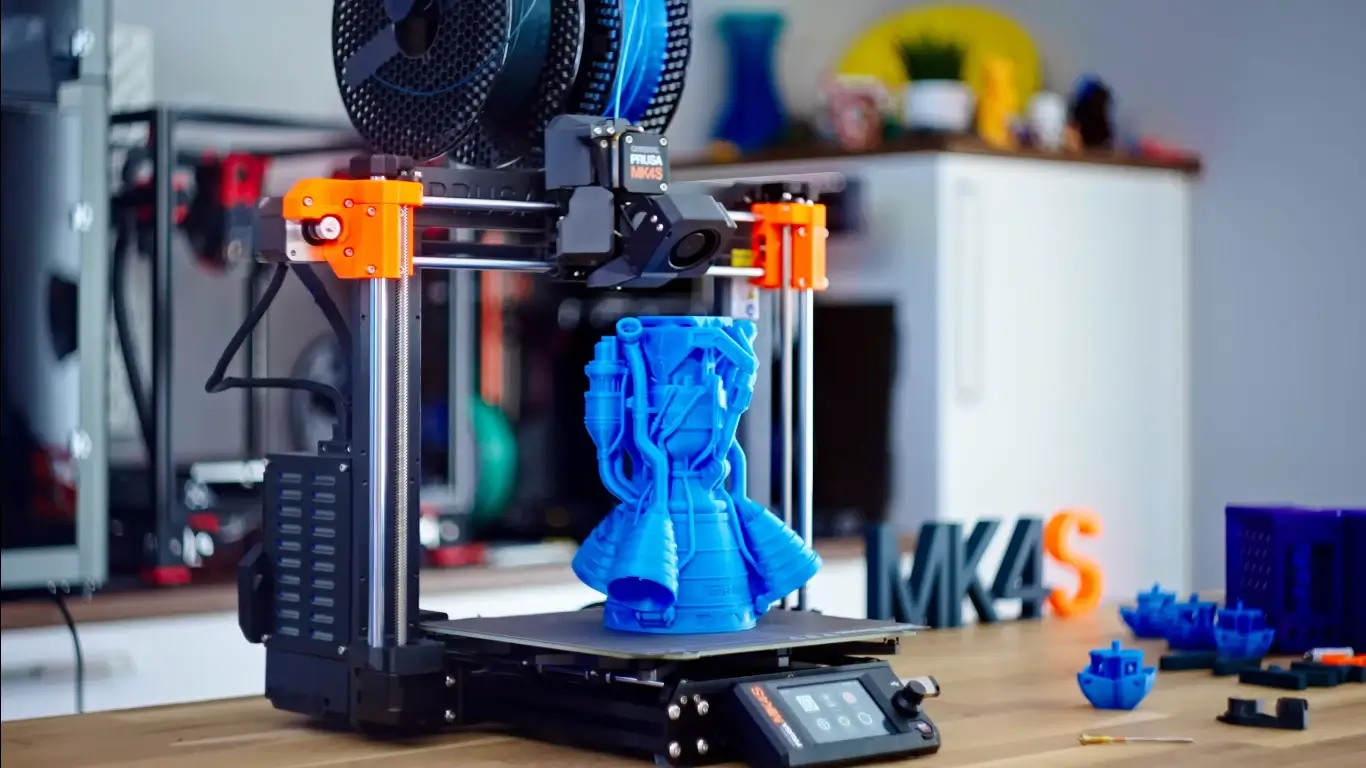

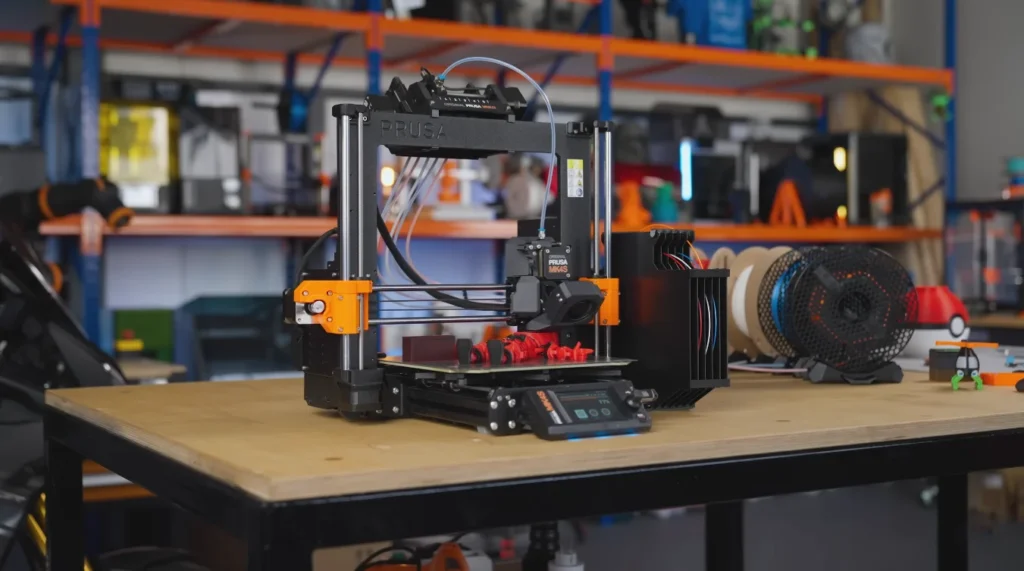

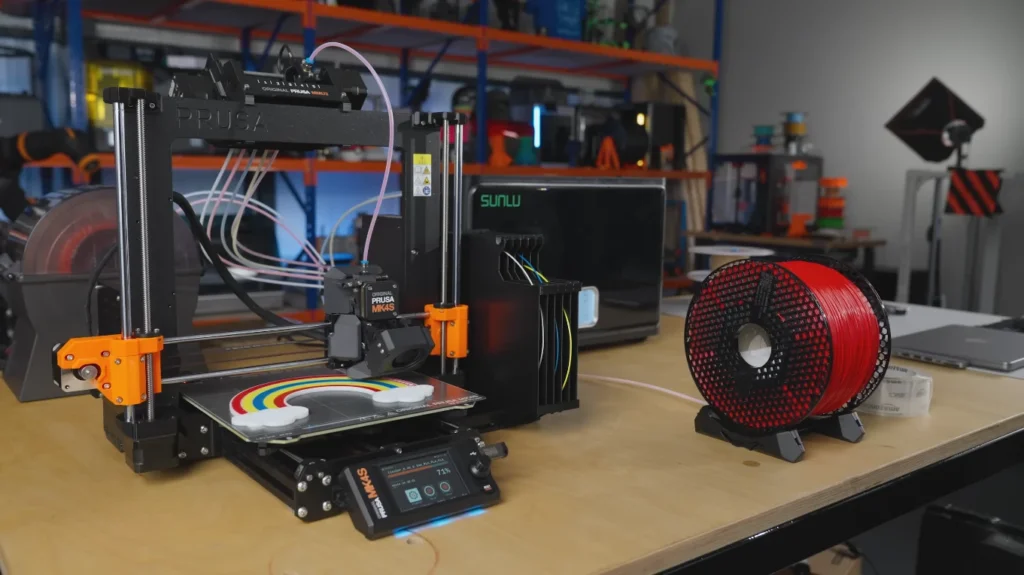

The Original Prusa MK4S is a perfect mix between a consumer and an industrial machine, delivering a sweet spot of performance. With its generous build volume of 250 x 210 x 220 mm, the MK4S builds upon Prusa’s reputation for reliability while pushing the boundaries of print speed and quality. This printer is particularly well-suited for workshops, maker spaces, and professional environments where consistent output is crucial.

Fresh from the factory, the Original Prusa MK4S comes ready for basic printing operations, but its true potential is unlocked through thoughtful additions like the Multi-Material Upgrade (MMU3) for multi-color printing and the optional enclosure for advanced materials. While these accessories enhance the printer’s capabilities, they do add to the initial investment.

One of the Original Prusa MK4S’s standout features is its refined 360° cooling system paired with the new Bondtech high-flow nozzle, representing Prusa’s commitment to continuous innovation. The printer’s integration with PrusaSlicer software and the Prusa Connect ecosystem provides an accessible entry point for newcomers while offering depth for experienced users.

Having tested and printed a large number of these printers, I feel ready to give my thorough impressions on this new offering from the Prusa lineup. The Original Prusa MK4S is not the cheapest desktop 3D printer on the market, but frankly, it shouldn’t be overlooked either given its speed, accuracy and user-friendly futures. Let’s explore whether this premium printer justifies its position in the market.

Original Prusa MK4S

Pros

Reliable and consistent output

Professional-grade quality

User-friendly operation

Cons

Premium price point

First Impressions and Setup

Right out of the box, Prusa maintains its welcoming touch by including gummy bears with the Original Prusa MK4S, and it feels as though every detail has been considered. This isn’t just a printer; it’s a toolkit, too. Packed with a full set of assembly tools, a spool holder, a Galaxy Black filament spool, and even Prusa’s own lubricant, it’s clear that Prusa understands what users need to get started right away.

The Original Prusa MK4S can be purchased fully assembled or as a DIY kit, which costs $799 (the pre-built option is $1,099). For those who enjoy the process, the kit is an excellent introduction to 3D printer mechanics, and Prusa’s clear assembly instructions make the build as engaging as it is informative. For those who prefer the fully assembled version, the MK4S offers a straightforward, plug-and-play experience.

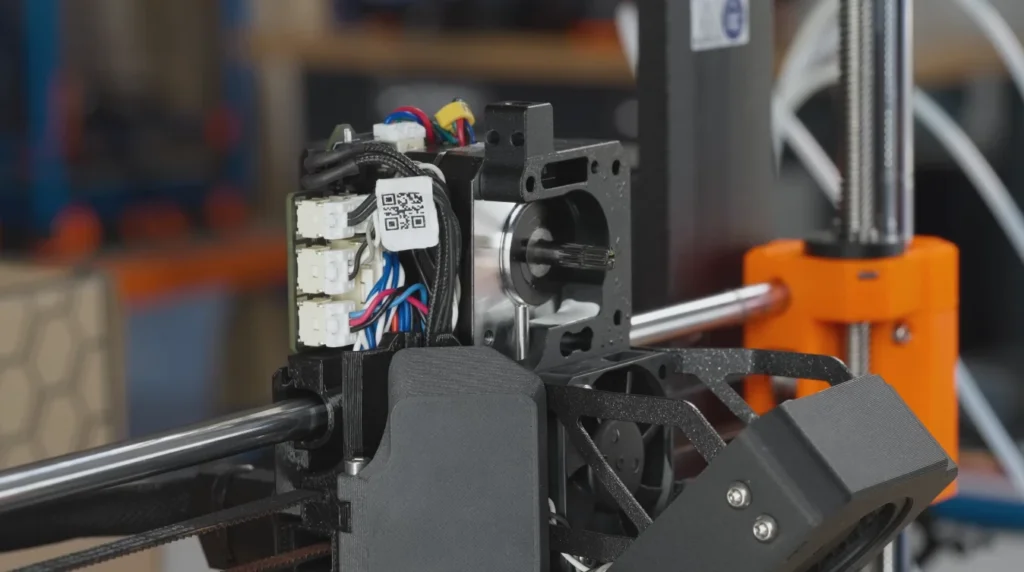

New Design and Functional Improvements

Built on Prusa’s reliable open-frame, “bed-slinger” design, the MK4S is the result of more than a decade of continuous refinement. The frame combines injection-molded plastic components and Prusament PC Blend Carbon Fiber, which gives the machine a solid, industrial feel. The open design allows for easy access to every component, which is beneficial for maintenance or when swapping out parts for custom modifications. This is especially valuable for educational or industrial environments where hands-on interaction with the machine is a regular part of the workflow.

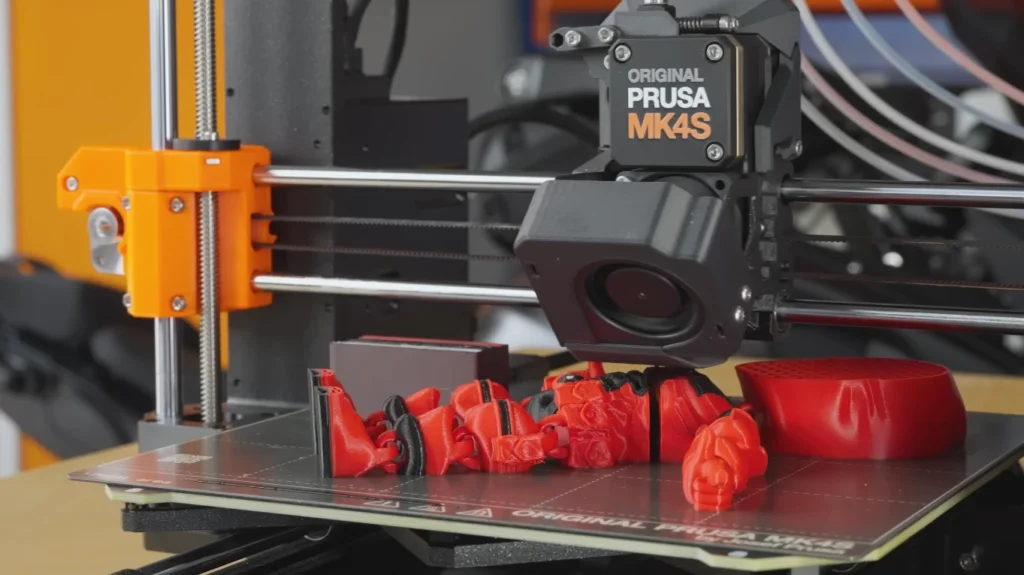

New Cooling and Extrusion Systems

One of the most significant upgrades in the Original Prusa MK4S is the 360° cooling system, a feature that wraps the print head in airflow to ensure even cooling. The benefit? Sharper, cleaner prints, even when handling difficult geometries or steep overhangs up to 75°. Paired with the new Bondtech high-flow nozzle, the MK4S achieves consistent extrusion at high speeds without compromising layer adhesion or surface finish.

In testing, this cooling system made a noticeable difference. The Original Prusa MK4S produced remarkably clean prints without the need for extensive supports, even on models with complex overhangs and intricate details. For professional users who prioritize print quality and speed, this improvement alone makes the MK4S an attractive option.

Enhanced Printing Speed and Precision

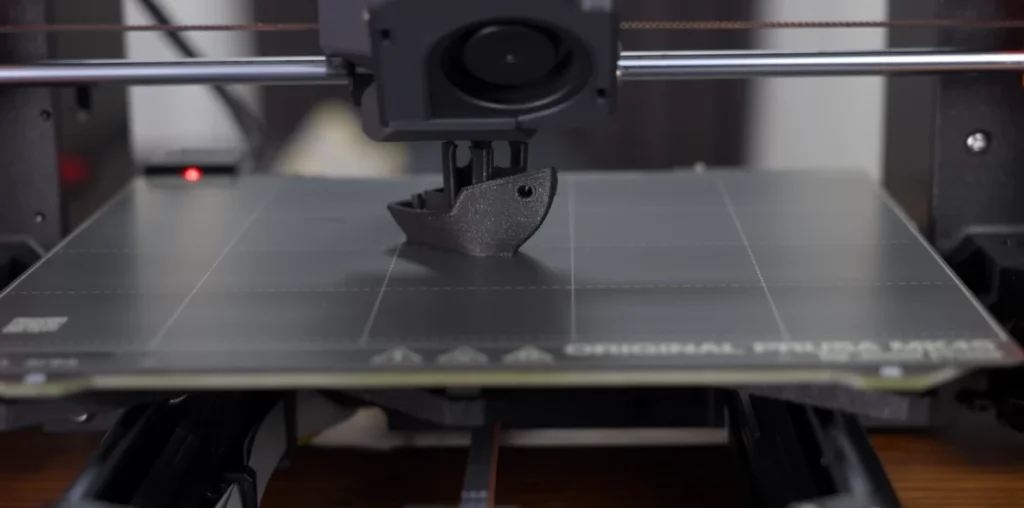

Prusa’s reputation has traditionally leaned more toward quality than speed, but with the MK4S, they’ve shown that the two aren’t mutually exclusive. During testing, theOriginal Prusa MK4S managed an impressive 8-minute Benchy—an astounding feat in 3D printing where speed often compromises detail. Not with this machine. The high-flow nozzle and optimized cooling keep the layers even and prevent any smudging or stringing, which can sometimes occur with high-speed settings.

One area where the Original Prusa MK4S truly shines is in handling intricate geometries and challenging overhangs. For example, printing an object with a 75° overhang, which would usually require supports, was achieved effortlessly due to the efficient cooling. This means users can print more complex models without investing extra time in post-processing, a major benefit for both hobbyists and professionals.

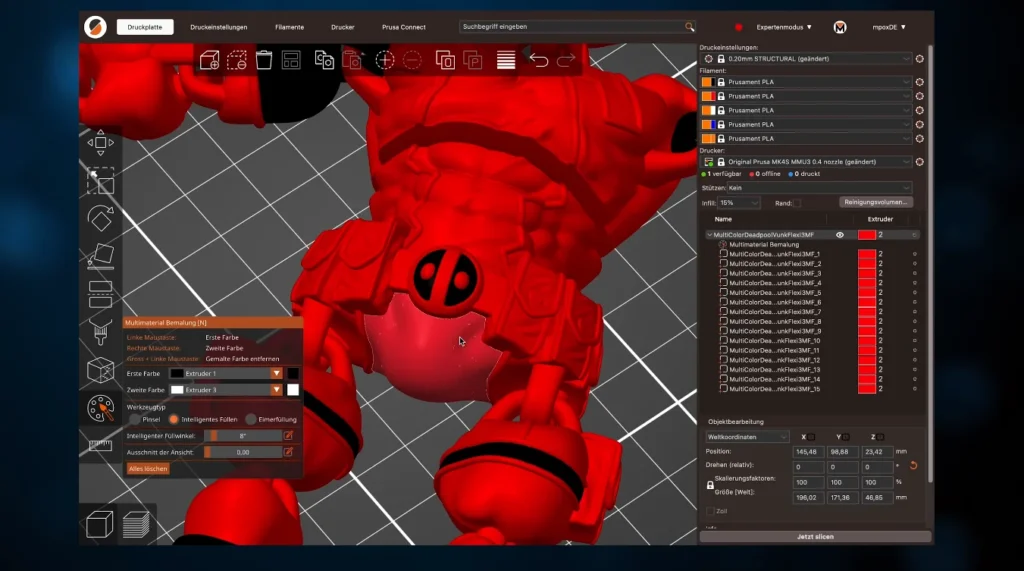

Software and Connectivity

Prusa has worked diligently to make the Original Prusa MK4S accessible and user-friendly. The Prusa Connect app, available on both mobile and desktop, brings convenient remote management. Setting up Wi-Fi on the MK4S is a breeze; just tap the NFC chip and scan a QR code, and you’re connected. Through the app, users can browse, upload, and start prints, and even receive real-time notifications about the printing status. For those who prefer offline printing, the MK4S still offers USB connectivity, maintaining its versatility.

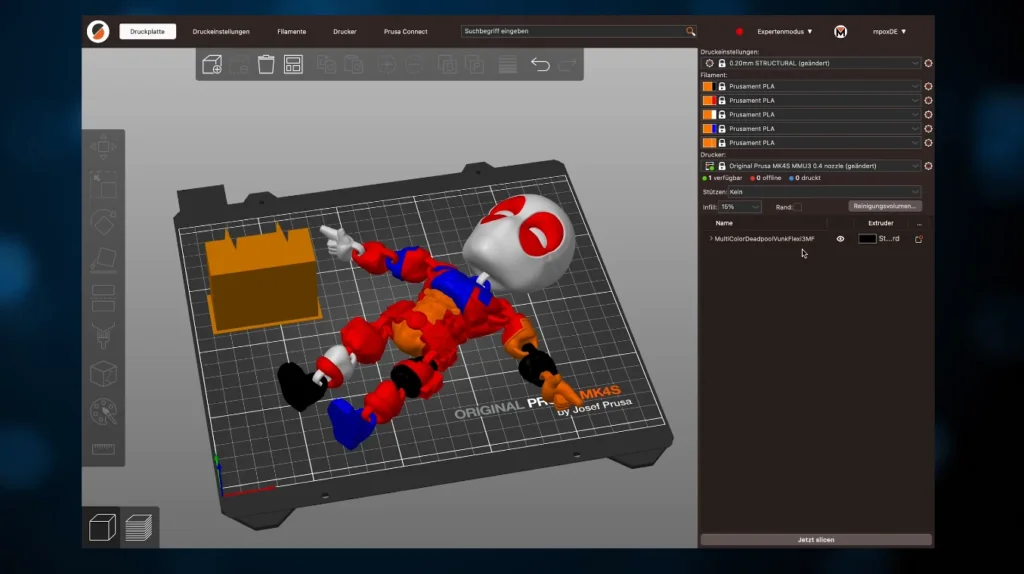

One standout feature in Prusa’s ecosystem is the PrusaSlicer software. With preset profiles tailored to the Original Prusa MK4S, slicing models for print is intuitive and quick. Users can select print profiles to optimize for speed, detail, or a balance of both, depending on their needs. The slicer supports a range of materials, from basic PLA to more advanced filaments like ASA and flexible TPU, giving users flexibility in their projects.

Print Quality and Reliability

Print quality on the Original Prusa MK4S is exceptional, thanks to Prusa’s focus on detail-oriented upgrades. Even at faster speeds, prints come out smooth, with consistent layers and fine surface finishes. A test print of Autodesk’s Kickstarter model showed how capable the MK4S is at handling fine details, such as narrow spires and intricate bridging, with minimal imperfections. The 360° cooling setup and Bondtech nozzle work together to avoid common issues like warping, overhang flaws, or ringing, even on challenging prints.

Dimensional accuracy is another strength of the Original Prusa MK4S. Prusa claims an average error of just 0.097 mm, a figure that was validated in testing with complex geometric shapes. For users working on functional parts where fit and accuracy are crucial, this level of precision is a major advantage. Additionally, the MK4S has an automated first-layer calibration system, ensuring a smooth, even base for every print. This reliable bed adhesion minimizes the risk of print failures due to lifting or warping, saving time and filament.

Built for Power Users, but Accessible to All

These upgrades from Prusa are not merely bells and whistles but functionality based. The Original Prusa MK4S offers optional accessories like the GPIO board, which opens up possibilities for advanced customization, such as adding a camera or other sensors. Users can also integrate an accelerometer, which allows for input shaping and vibration compensation—a feature that power users and modders will appreciate. These options highlight Prusa’s philosophy of creating machines that cater to both beginners and experienced users.

Connectivity options extend to Ethernet and Wi-Fi, giving flexibility in setup. Using Prusa Connect, the MK4S can be controlled remotely, and for those requiring privacy or working in high-security environments, the printer can operate entirely offline. Prusa’s open-source approach to firmware means users can customize and monitor operations without privacy concerns. Unlike many closed systems, Prusa’s transparency provides reassurance to users, including those in corporate or educational settings where data privacy is essential.

Original Prusa MK4S specification chart

| Feature | Specification |

|---|---|

| Build Volume | 250 x 210 x 220 mm |

| Layer Height | 0.05 – 0.30 mm |

| Nozzle | High-flow Bondtech, 0.4 mm |

| Max Nozzle Temp | 290°C |

| Max Bed Temp | 120°C |

| Extruder | Nextruder, Direct Drive |

| Cooling | 360° high-performance cooling |

| Calibration | Automated mesh bed leveling |

| Supported Filaments | PLA, PETG, ASA, TPU, ABS, PC |

| Connectivity | NFC, optional Wi-Fi, Ethernet, USB |

| Display | 3.5″ color LCD |

| Multi-Material | MMU3 add-on (up to 5 materials) |

| Price | $1,099 (assembled), $799 (DIY kit) |

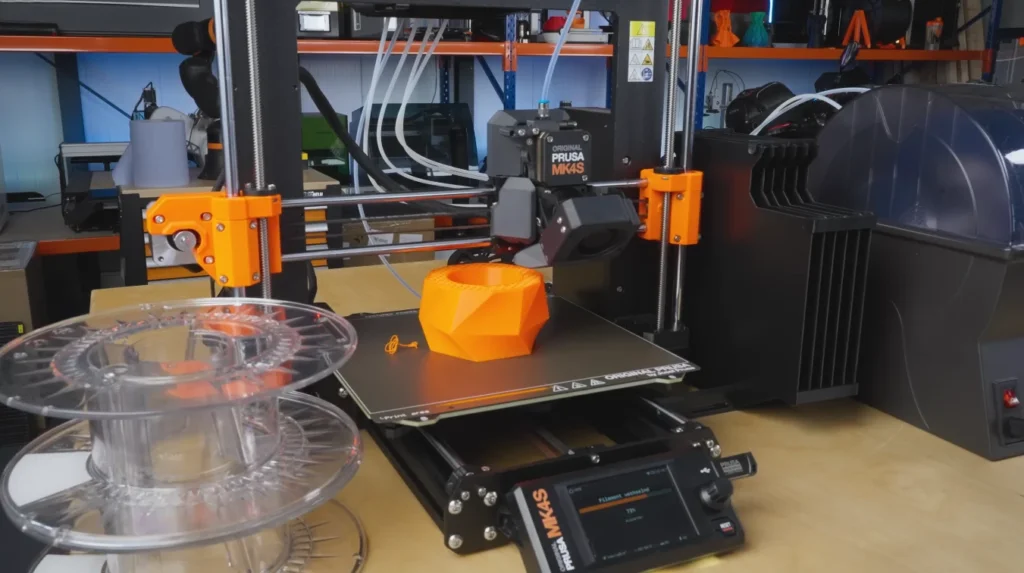

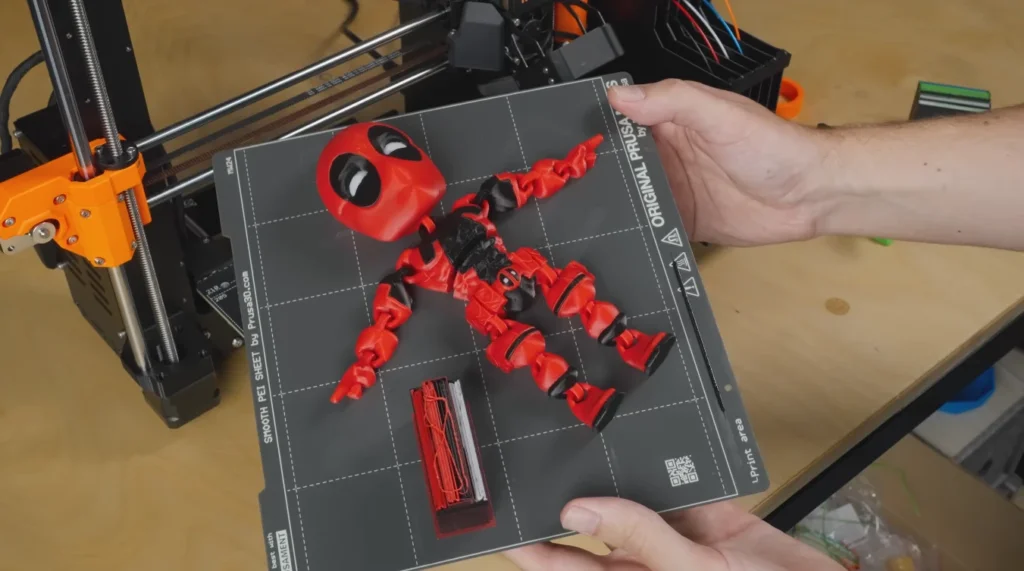

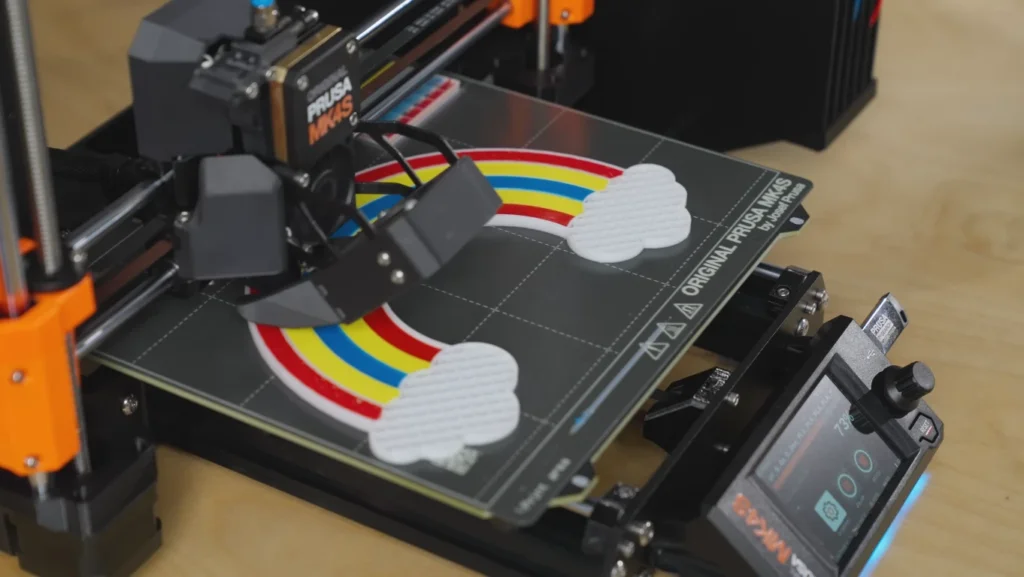

Multi-Material and Advanced Material Handling

With the Multi Material Upgrade (MMU3) add-on, the Original Prusa MK4S can handle up to five colors or materials simultaneously, a feature that sets it apart in the market. This functionality is ideal for users who want to experiment with multi-color or multi-material prints, whether for aesthetic or functional purposes. The MMU3 has been redesigned to be faster and more efficient than previous versions, reducing filament waste by up to three times compared to other multi-material systems. When paired with the MK4S’s standard nozzle, the MMU3 strikes an optimal balance between speed and material conservation.

Material compatibility is another strong point. The Original Prusa MK4S handles a wide range of filaments, from PLA and PETG to tougher materials like carbon-filled filaments and flexible TPU. The direct drive Nextruder system, combined with the high-flow nozzle, ensures reliable extrusion, even with more demanding filaments. For printing in materials like ABS or ASA, Prusa offers an optional enclosure to help stabilize the temperature, reduce odor, and increase print success for these higher-demand materials.

Material Compatibility and Enclosure Options

The MK4S supports a broad range of materials, from beginner-friendly PLA and PETG to more advanced options like carbon-filled filaments and flexible TPU. To support printing with ABS, ASA, and other high-temperature materials, Prusa offers an enclosure bundle. The enclosure stabilizes the internal environment by reducing temperature fluctuations, protecting against drafts, and containing fumes. With additional options like HEPA filtration and a fire suppression system, the enclosure makes the MK4S adaptable for industrial or educational settings that may require enhanced safety and material performance.

User Experience and Usability

The MK4S embodies Prusa’s dedication to user-centered design. The printer’s 3.5-inch color LCD screen is intuitive and easy to navigate, with high contrast that makes it visible in various lighting conditions. The addition of status LEDs and a one-click print feature brings even more convenience, while the modular GPIO and accelerometer options cater to advanced users who enjoy fine-tuning their setup or adding extra features like custom lighting or cameras.

Furthermore, the MK4S excels at maintaining a seamless user experience thanks to its automated calibration and print recovery systems. The machine’s “Power Panic” function allows prints to resume automatically after a power outage, and the filament sensor prevents run-outs, ensuring that users can set up a print and leave it without worry. Prusa’s emphasis on minimal downtime is evident, making this model suitable for both professional and personal use.

Modular Accessories and Add-Ons

The Original Prusa MK4S supports a range of modular accessories that expand its functionality. Key among these is the Multi-Material Upgrade (MMU3), which allows printing with up to five different filaments in a single job. This capability is ideal for users who need multi-color or multi-material outputs, as it enhances design flexibility without requiring separate printers. Additionally, Prusa has designed the MMU3 to be more efficient in terms of filament waste compared to previous models, achieving faster filament changes and optimized nozzle cleaning.

Other add-ons include the optional GPIO hacker board and accelerometer, tailored for users interested in advanced modifications. The GPIO board allows custom electronics integration, such as controlling external devices through G-code, while the accelerometer provides input shaping, which helps reduce vibrations and enhance print stability. These add-ons make the MK4S a highly customizable machine for advanced users or those working in specialized applications.

Real-World Usability and Long-Term Reliability

The MK4S proves itself as a workhorse capable of handling continuous print jobs without frequent adjustments. For professionals and educators who require consistent, reliable output, the MK4S’s design minimizes downtime. From batch printing small parts to running large, intricate models, the MK4S handled each project with minimal user intervention. A quick look at the machine’s specs, like the custom 32-bit mainboard and precision Trinamic drivers, shows Prusa’s focus on durability and long-term performance.

Customer feedback reflects the MK4S’s reliability. With over half a million Prusa printers in use globally and a return rate of less than 1%, the brand has established a strong reputation for quality. Users frequently report minimal maintenance needs, and the machine’s modular, open design makes repairs straightforward when necessary. Plus the 24/7 support and thorough documentation from Prusa is an added bonus for hobbyists and professionals alike.

Long-Term Upgradability and Support

The long-term support and modular upgrades from Prusa guarantee that the MK4S will remain relevant overtime. For existing users, the MK4 to MK4S upgrade kit retails for $100 and gives you access to the same features behind their latest machines which include their 360° cooling system and high-flow nozzle. This modular approach reflects Prusa’s user-focused philosophy, as they prioritize ongoing support and improvements through firmware updates and readily available replacement parts. This adaptability has made the MK4S a reliable investment for both hobbyists and professionals looking for a machine that grows with their needs.

Drawbacks and Considerations

While the Original Prusa MK4S impresses in many areas, it has some limitations to consider. While you can buy the assembled model for $1,099, and the kit version costs $799, that’s pricier than other “bed-slinger” 3D printers. The increased price may deter newcomers or casual hobbyists that are just getting into 3D printing.

The open-frame design, though convenient for access and maintenance, might not be ideal for every workspace. An optional enclosure is available, but this adds to the overall cost, and for those using the MK4S in an environment where temperature control and safety are critical, an enclosed printer might be preferable.

Lastly, while the MK4S brings meaningful upgrades, owners of the MK4 might find the enhancements too incremental to justify a new purchase. For these users, the $100 upgrade kit from MK4 to MK4S may offer a more practical alternative.

Should You Buy the Original Prusa MK4S?

Buy the MK4S if:

- You Want an a Fast Speed With Print Quality – The high flow nozzle and cooling on the MK4S gives you speedy prints without compromising details.

- You need multi-material capabilities – With the MMU3 add-on, the MK4S is excellent for multi-color and multi-material prints.

- You value long-term reliability – Prusa’s support and upgrade options ensure the MK4S remains a reliable, long-term investment.

Don’t buy the MK4S if:

- You’re on a tight budget – The MK4S’s premium price may not suit beginners or casual users.

- You need a fully enclosed printer by default – The open-frame design might be limiting in settings that require an enclosure.

Final Thoughts

The Original Prusa MK4S is available in two versions: the pre-assembled version priced at $1,099 and a DIY kit for $799. But the MMU3 upgrade, along with an enclosure, can drastically raise this complete price whilst also broadening the printer’s skillsets significantly.

As a standalone unit, the MK4S delivers exceptional print quality and reliability, particularly excelling in high-speed operations while maintaining precision. However, to fully unlock its potential with advanced materials and multi-color printing, the additional accessories (enclosure, MMU3) can push the total cost significantly higher, potentially bringing it into competition with more specialized industrial printers.

The MK4S is an easy recommendation for users who prioritize reliability, print quality, and the backing of a proven ecosystem. Its combination of automated features, precision components, and extensive upgrade options make it particularly appealing for professional users and serious enthusiasts. However, if pure print speed or build volume is your primary concern, it’s worth exploring our list of the best 3D printers, which includes more specialized machines that might better suit specific needs.

The upgrade decision depends on your specific needs. If print speed and cooling performance are crucial for your work, the $100 upgrade kit from MK4 to MK4S offers significant value through its 360° cooling system and high-flow Bondtech nozzle. However, if you are happy with how your MK4 prints, and don’t need faster print speeds nor better cooling for overhangs, the upgrade might not be really necessary.

The MK4S features an automated mesh bed leveling system that creates a detailed map of the print surface. The system measures multiple points across the bed and compensates for any slight variations in height. Testing shows an average dimensional accuracy of 0.097mm, making it highly reliable for consistent first layers. The calibration process runs automatically before each print, requiring no user intervention.

The MK4S can print PLA, PETG, TPU, and ASA without modification. The printer supports temperatures up to 290°C for the nozzle and 120°C for the bed. However, for materials like ABS or carbon-filled filaments, Prusa recommends using their optional enclosure to maintain stable temperatures and contain fumes. The direct-drive Nextruder system handles flexible materials particularly well.

The MMU3 upgrade isn’t necessary for basic printing but adds significant versatility if you need multi-color or multi-material printing capabilities. It allows up to five different materials or colors in a single print. Consider the upgrade if you:

- Regularly need multi-color prints

- Work with soluble supports

- Require different materials in the same print

- Want to automate material changes for batch printing

The DIY kit ($799) typically takes 4-6 hours to assemble for someone with moderate technical experience. Prusa provides detailed, step-by-step instructions and all necessary tools. While the assembled version ($1,099) saves time, building the kit offers valuable insights into the printer’s mechanics and makes future maintenance easier. First-time builders should set aside a full day to ensure careful assembly without rushing.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.