Hi guys Robb Koch this side, as a long-time fan of 3D printing and laser engraving, I’ve shared my experience using and testing various machines in various posts. So when Snapmaker announced the latest “Ray” laser engraver my ears perked up. The Snapmaker Ray is the debut standalone laser engraver from leading modular 3D printer manufacturer, known for their high quality consumer-grade products. It’s the hands-on review of mine with Snapmaker new member Ray 40W laser engraver and cutter.

First Impressions and Setup

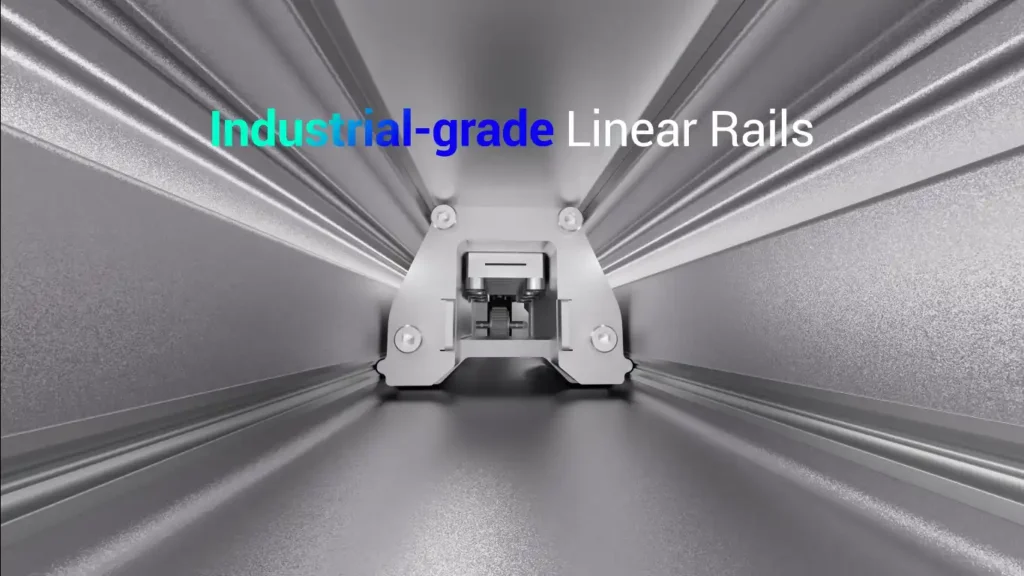

Right out of the box, the Snapmaker Ray exudes quality. This machine is solidly built with thick aluminum parts and a large laser head, clearly designed for power and endurance. Hidden within the machine’s frame are sturdy steel rails that guarantee steady performance, no matter how fast it moves.

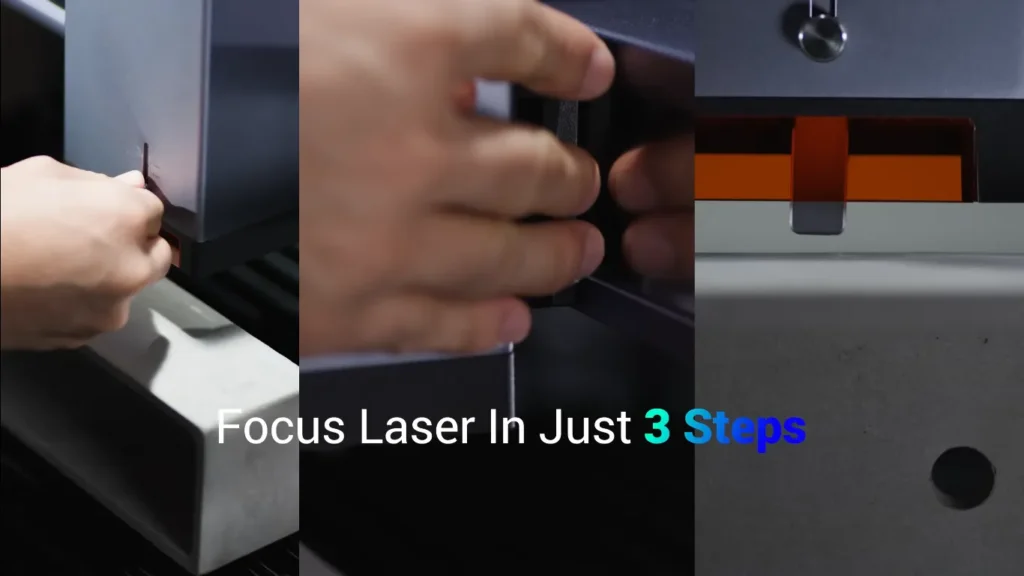

Assembly was straightforward, though I did find myself wishing for more detailed instructions at times. The components fit together seamlessly, a testament to Snapmaker’s precision manufacturing. However, cable management proved to be a bit of a challenge. Unlike some of their other models, the Ray lacks a drag chain for cable management, which is surprising given its price.

The fully enclosed model I tested has brown acrylic panels that protect users from laser hazards. This enclosure not only adds an extra layer of safety but also gives the Snapmaker Ray a sleek, professional appearance.

Specs and Features

The Snapmaker Ray 40W boasts impressive specifications:

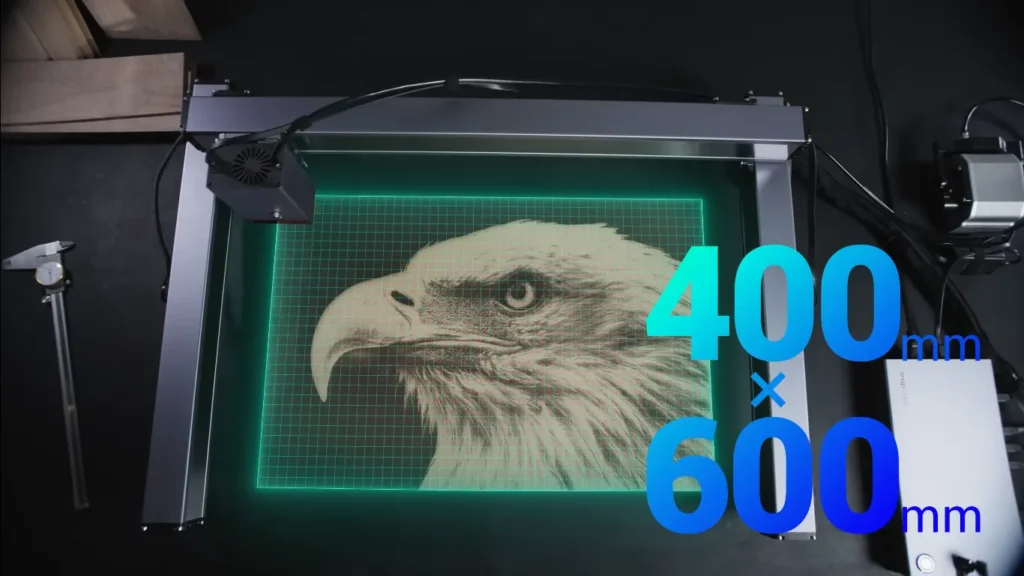

- Work area: 400mm x 600mm

- Maximum work speed: 500mm/s

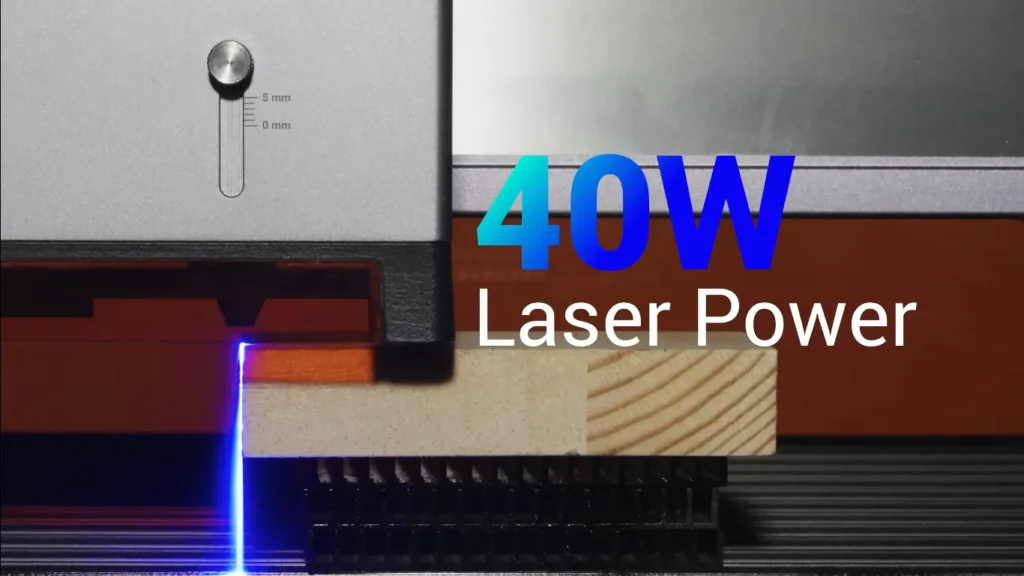

- Laser output power: 40W

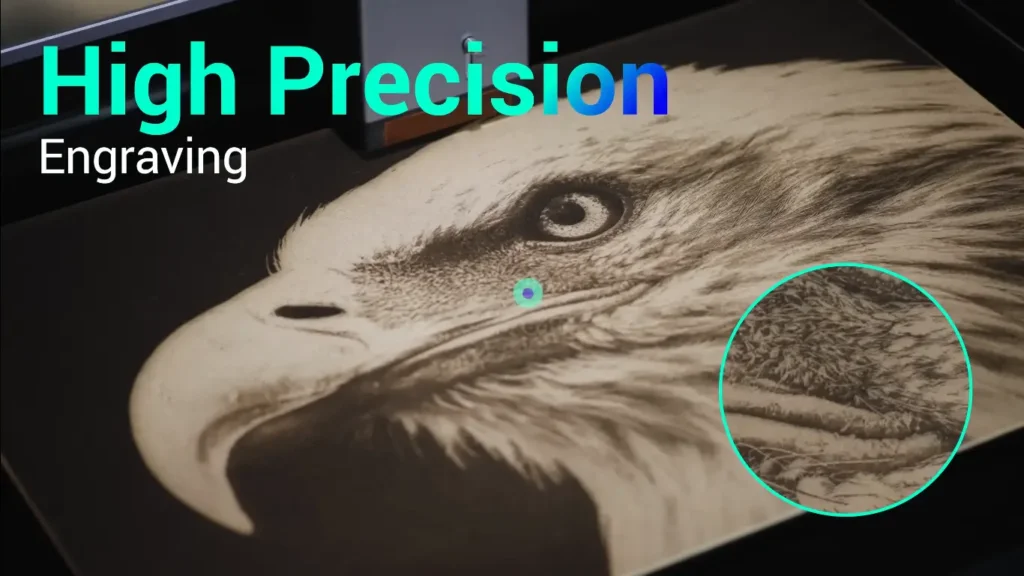

- Laser spot dimensions: 0.1mm x 0.15mm

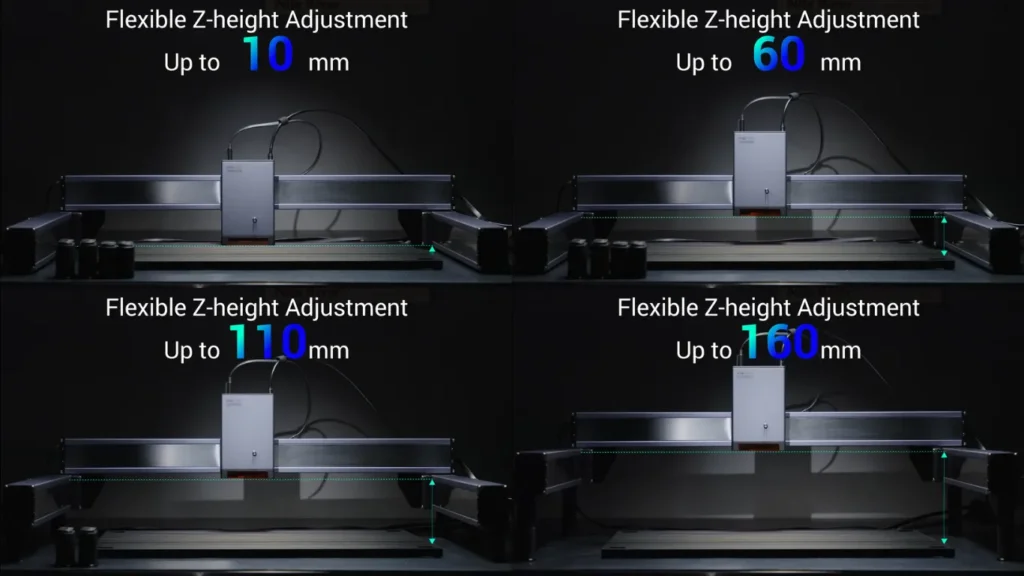

- Maximum workpiece height: 160mm (with two sets of cylindrical feet)

One of the standout features is the built-in air assist system. This not only helps prevent laser burns during operation but also keeps the laser lens clean, reducing maintenance needs.

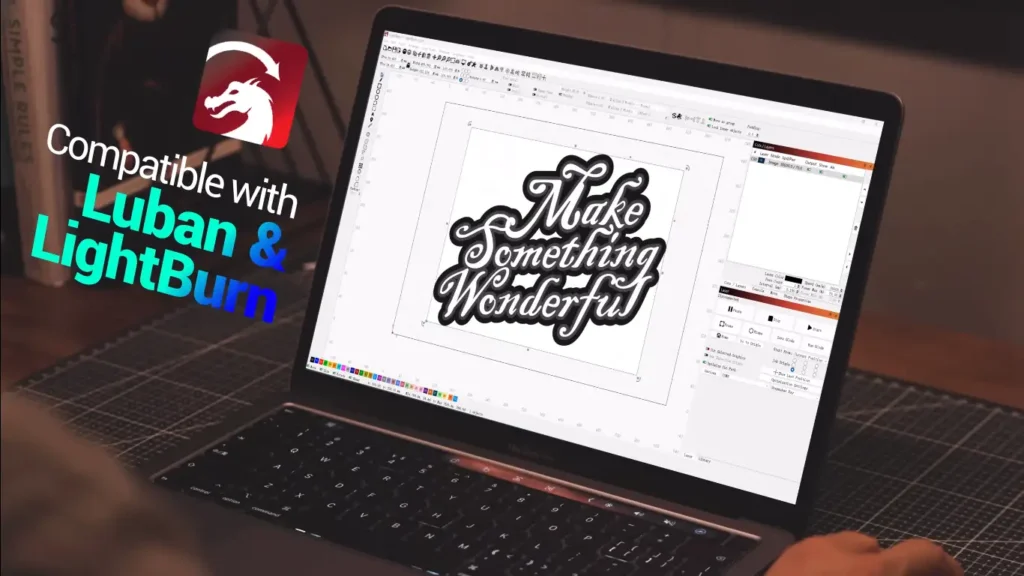

The Snapmaker Ray works with Snapmaker’s own Luban and the popular LightBurn software. This gives you many design and control options. Connectivity is versatile, with both Wi-Fi and USB options available.

Performance Testing

I put the Snapmaker Ray through its paces with a variety of materials and projects. Here’s how it performed:

- Plywood Cutting: Starting with a 15mm basswood plywood, I was impressed by the Ray’s ability to cut through in a single pass. The cuts were clean and precise, with minimal charring on the edges. Even intricate designs with thin lines came out beautifully, showcasing the laser’s accuracy.

- MDF Engraving and Cutting: Moving on to 6mm MDF, the Ray performed admirably. Engravings were sharp and detailed, while cuts were clean without any noticeable deformation. However, when I tried 1.8mm MDF, I encountered some burning issues at higher power settings. This highlights the importance of fine-tuning your settings for different materials and thicknesses.

- Leather Work: Both genuine and faux leather yielded excellent results. Engravings were crisp without any burn marks, and cutting through even small, intricate parts was a breeze. The air assist really shines here, preventing any scorching on the material.

- Fabric and Felt: Denim and felt were next on my list. The Snapmaker Ray cut through these materials quickly and cleanly. Engraving on denim produced clear, detailed results that could be perfect for customized clothing items.

- Acrylic Challenges: With 2.8mm black acrylic, the Ray performed exceptionally well, producing sharp cuts without any melting. However, I encountered issues with white and transparent acrylics. The laser tended to cause melting and deformation, especially on thinner parts. This limitation is worth noting for those planning to work extensively with light-colored or clear acrylics.

- Metal Engraving: While the Ray isn’t designed for metal cutting, it can engrave on certain metals. I tested it on stainless steel, and by varying the speed and power, I was able to achieve different tones like blue, yellow, red, and gray. The results were impressive, opening up possibilities for metal signage and decorative items.

- Speed and Efficiency: One of the most striking aspects of the Ray is its speed. At 500mm/s maximum work speed, it’s significantly faster than many competitors in its class. This speed, combined with its power, allows for quick completion of projects that would take much longer on other machines.

Software and User Experience

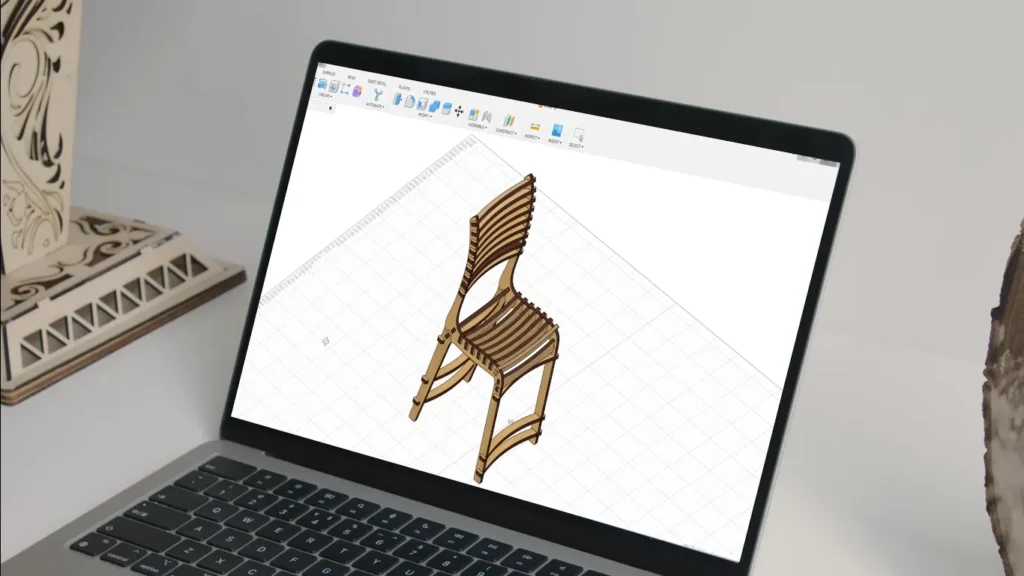

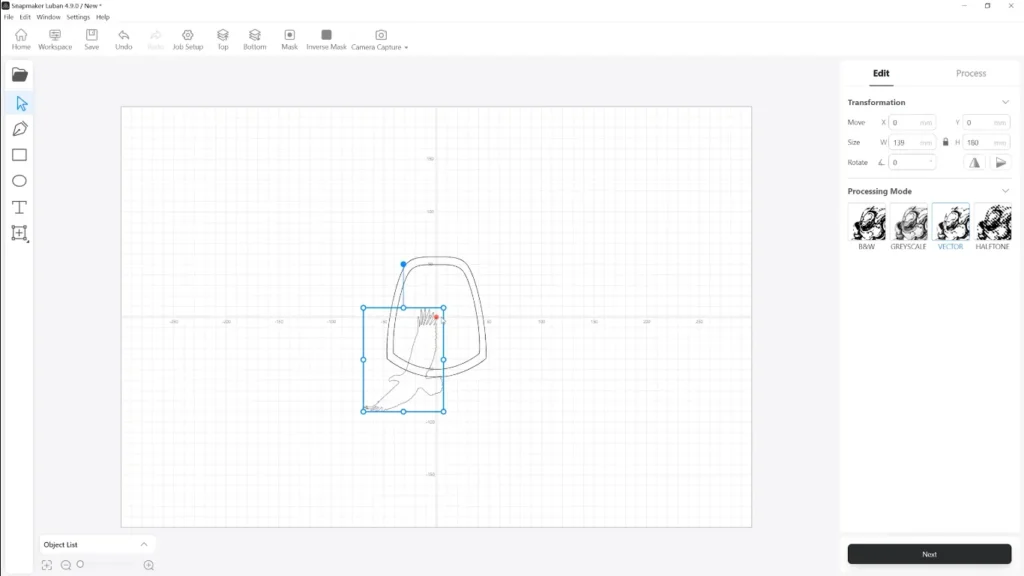

The Snapmaker Ray comes with its own Luban, the company’s own software. It comes with a very simple user interface which is easy to use, so even beginners won’t have an issue. However, for experienced laser users, Luban might feel a bit basic.

Here’s where LightBurn compatibility shines. LightBurn offers a much wider range of features and tools, giving you more control over your laser projects. It integrates seamlessly with the Ray, handling everything from movement control to generating the cutting instructions (G-Code).

One minor drawback: the Snapmaker Ray itself doesn’t have a built-in screen. Everything is controlled through software. This might be an adjustment for users who are used to having controls directly on the machine.

Safety Features

Safety is your top priority when using the Ray. The machine is designed with safety in mind. Its enclosed case protects you from laser harm and automatically stops the laser if you open it while it’s working. The goggles included are a good start, but you should get better ones made for your specific laser.

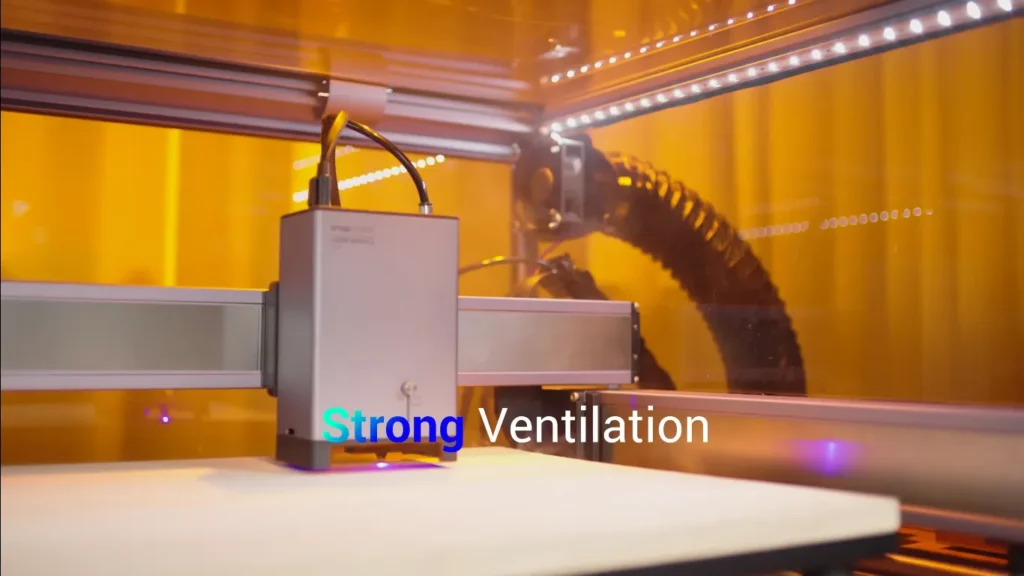

The Snapmaker Ray has a fan to help with smoke and dust. But if you use it a lot or with materials that make lots of fumes, you should get a Snapmaker Air Purifier or something similar. This will keep the air clean where you’re working.

To stay safe, always use the Ray in a well-ventilated area. Wear the right safety gear, and consider adding an air purifier for extra protection.

Versatility and Upgradability

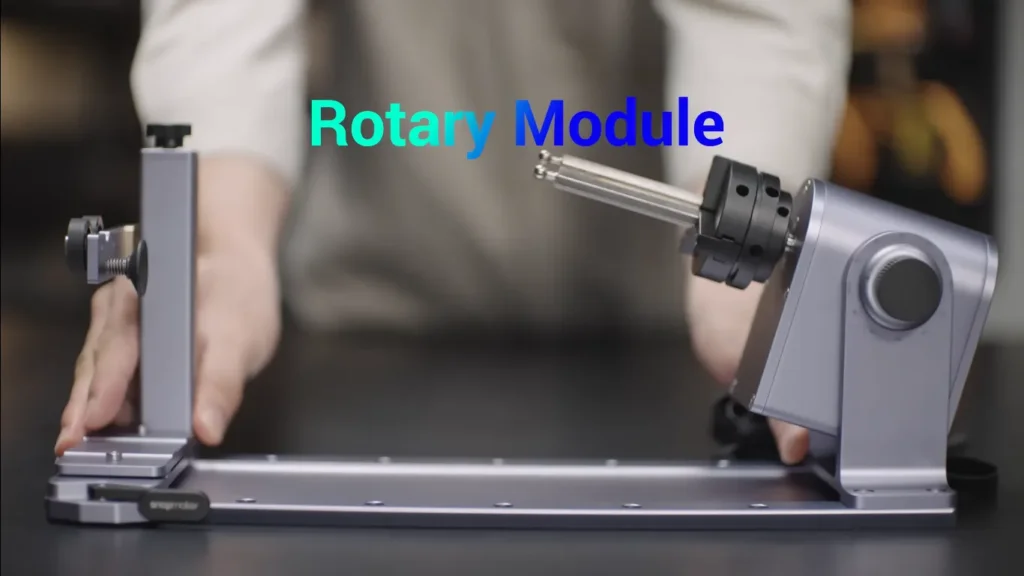

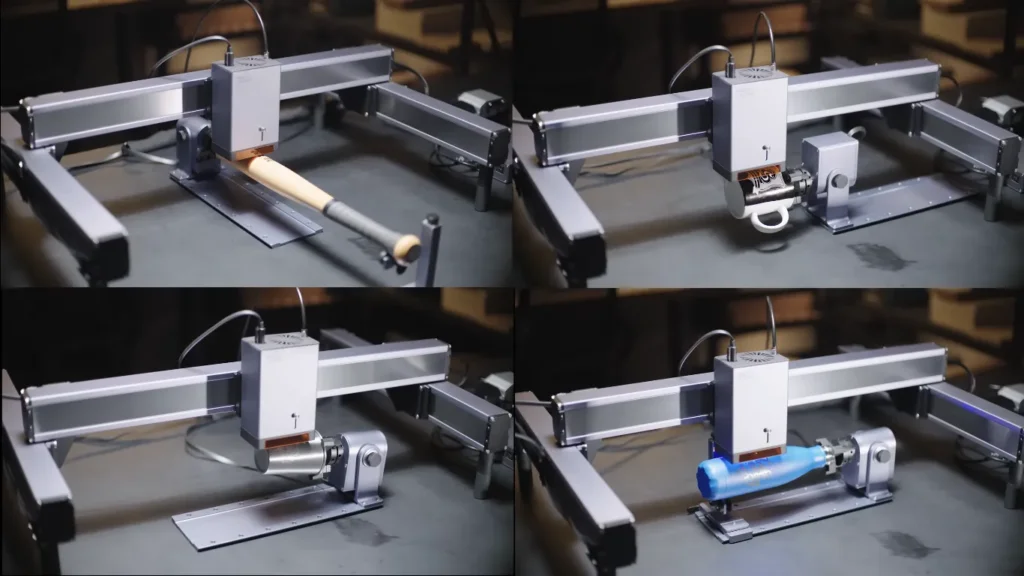

The Snapmaker Ray is built with flexibility in mind. Its laser part can be swapped out for different options, like more powerful lasers in the future. You can also use a special attachment to engrave things that are round.

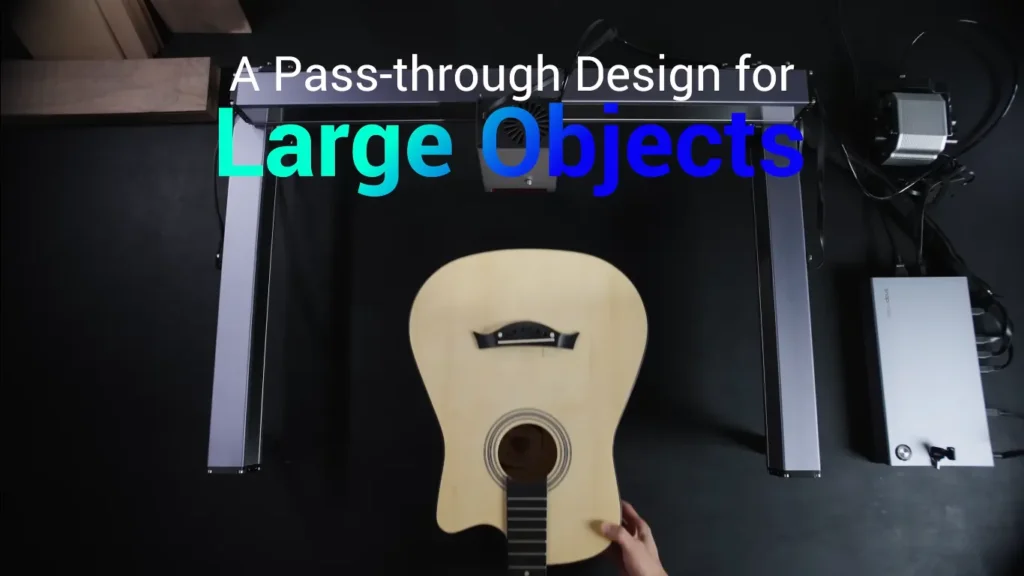

The large work area (400mm x 600mm) is generous, allowing for sizable projects. With the ability to raise the machine using cylindrical feet, you can work with objects up to 160mm in height, which is quite impressive for a machine in this class.

Pros nad Cons

Pros ✅

+ Powerful 40W laser capable of cutting

+ High-quality build with durable components

+ Large work area

+ Impressive speed (up to 500mm/s)

+ Built-in air assist for cleaner cuts and engravings

+ Fully enclosed design for safety

+ Compatibility with both Luban and LightBurn software

+ Modular design allowing for potential future upgrades

Cons 📛

– Cable management could be improved

– Luban software feels basic

– Struggles with light-colored and transparent acrylics

– No built-in screen for on-machine controls

– Relatively high price point, though justified by its features

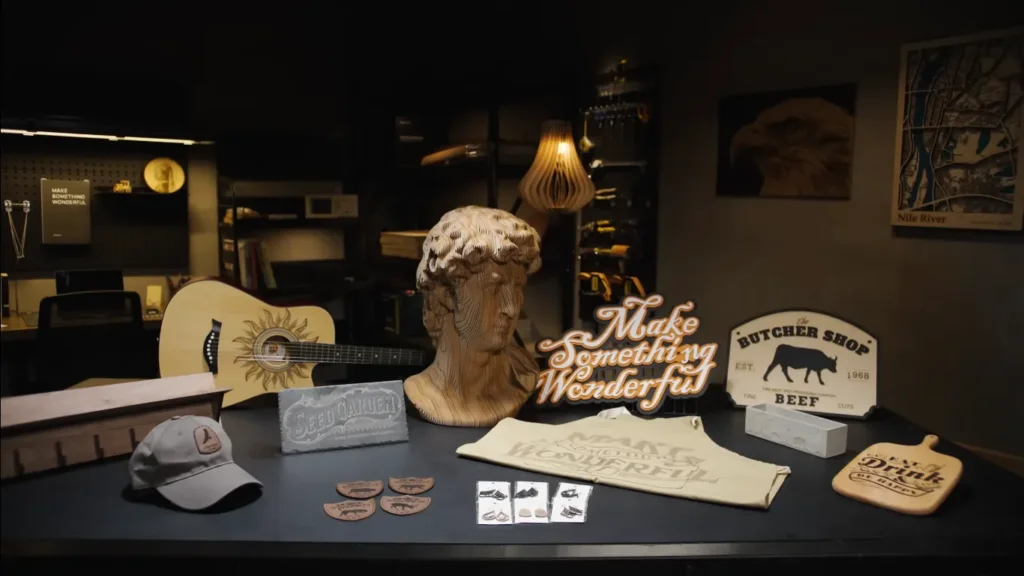

Real-World Projects

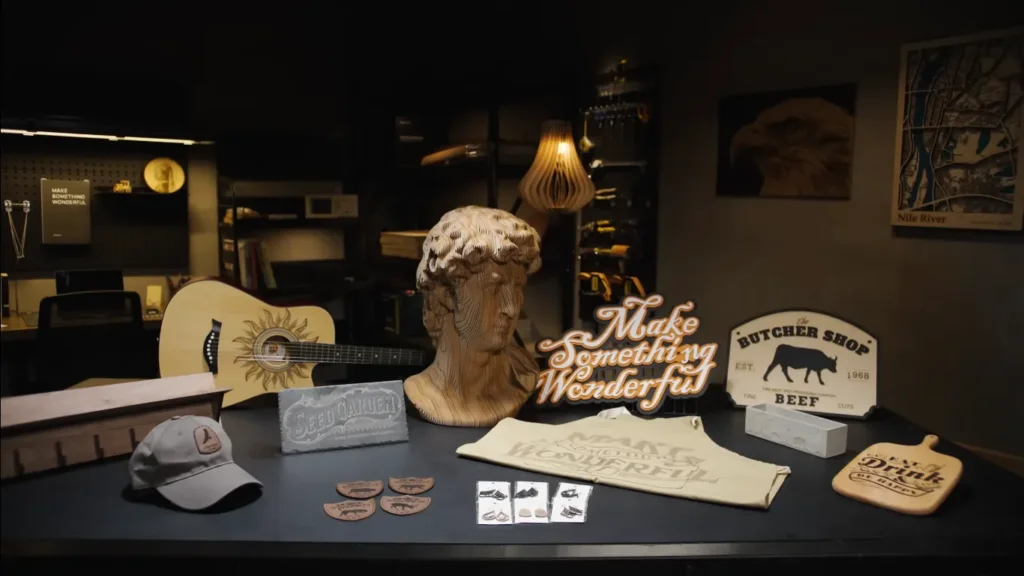

To really put the Snapmaker Ray through its paces, I tackled a few real-world projects:

- Custom Signage: I created a multi-layered wooden sign for a local business. The Ray’s ability to cut through 15mm plywood in one pass saved significant time, and the precision allowed for intricate lettering that came out beautifully crisp.

- Leather Wallet Panels: The clean cuts and engravings on leather made creating custom wallet panels a breeze. The speed of the Ray allowed me to produce multiple designs in a fraction of the time it would have taken with my previous setup.

- Engraved Stainless Steel Tumbler: While not able to cut metal, the Ray’s engraving capabilities on stainless steel were impressive. I created a custom design on a tumbler, and the varying tones achieved by adjusting speed and power added depth to the final product.

- Fabric Patch Cutting: The Snapmaker Ray’s ability to cleanly cut fabric without fraying edges made producing custom patches for a local sports team quick and easy.

- Acrylic LED Sign: Despite the challenges with clear acrylic, I managed to create a stunning edge-lit LED sign by carefully adjusting the settings. The precision of the engraving allowed for intricate details that really popped when illuminated.

Long-Term Considerations

The Snapmaker Ray has proven to be a reliable workhorse after several weeks of use. Its sturdy build suggests it can handle regular use for hobbies or small businesses. Maintenance has been minimal, with the air assist effectively keeping the lens clean. However, the enclosure panels require more frequent cleaning due to smoke residue, especially after longer cutting jobs.

The Ray’s modular design makes it a promising investment. Its potential for future upgrades or additions, like the rumored 1064nm infrared laser module, is appealing for those seeking a versatile tool that can grow with their needs.

The Snapmaker Ray’s solid construction and low maintenance requirements make it a practical choice. Its modularity offers flexibility for future projects, ensuring it remains a valuable asset over time.

Specification Chart for Snapmaker Ray 40W

| Feature | Specification |

|---|---|

| Laser Power | 40W |

| Work Area | 400mm x 600mm |

| Max Work Speed | 500mm/s |

| Max Cutting Speed | 20mm/s |

| Laser Spot Dimensions | 0.1mm x 0.15mm |

| Laser Type | 450 – 460nm Semi-conductor |

| Max Workpiece Height | 160mm (with two sets of cylindrical feet) |

| Dimensions (without enclosure) | 849mm × 600mm × 303mm |

| Weight (without enclosure) | 15.06 kg |

| Supported File Formats | STL, SVG, JPEG, PNG, JPG, BMP, DXF, SNAPLZR |

| Software Compatibility | Luban, LightBurn |

| Connectivity | Wi-Fi, USB |

| Price (40W with enclosure) | $1,599.00 (Offer price, regular $1,999.00) |

| Price (40W without enclosure) | $1,299.00 (Offer price, regular $1,599.00) |

Comparison to Competitors

In the realm of 40W laser engravers, the Snapmaker Ray holds its own against competitors like the Glowforge Pro or the Flux Beamo. The Ray’s speed is a significant advantage, often outpacing others in its class. Its build quality is also top-notch, matching or exceeding that of more expensive machines.

Where it falls slightly behind is in the software department. While Luban is user-friendly, it lacks some of the advanced features found in proprietary software of competitors. However, the LightBurn compatibility largely mitigates this issue for power users.

The Snapmaker Ray’s large work area is another point in its favor, offering more space than many competitors without a significant price increase.

Conclusion

The Snapmaker Ray 40W is an awesome laser cutter and engraver. It’s really fast, super precise, and packs a punch. Snapmaker has a great reputation, and this machine definitely lives up to it. Whether you’re just starting out or running a small business, this laser can handle it.

It’s safe to use because it’s enclosed and has lots of safety features. You can work on big projects because it has a large work area, and you can use it with all sorts of materials. Plus, you can make it even better later on by upgrading it.

It’s not perfect though. The cables could be tidier, and the software can be tricky at times. Also, it might have trouble cutting certain types of plastic.

Even with those little problems, it’s totally worth the money. You can start with simple stuff and work your way up to more complex projects.

This laser is great for everyone, from beginners to pros. It’s easy to use but also has powerful features.

FAQs

How does the Snapmaker Ray compare to CO2 lasers?

The Snapmaker Ray uses a diode laser, which is more compact and energy-efficient than CO2 lasers. While CO2 lasers can cut thicker materials, the Ray offers good performance for its size and price, especially for wood, acrylic, and fabric cutting and engraving.

Is Snapmaker a Chinese company?

Yes, Snapmaker is a Chineese Technology company that was founded in 2016. In addition to using 3D printers, they formed a Chinese company that has earned recognition worldwide for their trailblazing work in the field with laser engravers created by themselves stationed at their office in Shenzhen.

Can the Snapmaker cut metal?

The Snapmaker Ray 40W laser cannot cut metal. It even has metal engraving capability up to stainless steel and anodized aluminum. For metal cutting, you’d need a more powerful laser or a CNC module. Always refer to the user manual for compatible materials.

Can Snapmaker cut glass?

Snapmaker laser modules, including the Ray, cannot cut glass. They can engrave on certain types of glass, creating frosted or etched effects. For best results, use dark or colored glass. Always test on a small area first and adjust settings carefully.

Is Snapmaker good for CNC?

Snapmaker’s 3-in-1 machines offer good CNC capabilities for hobbyists and small projects. While the Snapmaker Ray is laser-only, Snapmaker’s other models like the Artisan provide CNC functionality. They’re user-friendly and versatile, but for heavy-duty CNC work, dedicated CNC machines might be more suitable.

Can Snapmaker cut acrylic?

Yes, the Snapmaker Ray can cut acrylic effectively, especially darker colors. It performs well with black acrylic up to about 8mm thick. However, it may struggle with clear or light-colored acrylics, potentially causing melting or deformation. Always test and adjust settings for optimal results.

What materials can a Snapmaker laser cut?

Snapmaker lasers, including the Snapmaker Ray, can cut various materials such as wood (up to 15mm thick), plywood, MDF, leather, fabric, paper, cardboard, and certain plastics like acrylic. They can also engrave on these materials plus some metals and glass. Always check the manual for compatible materials.

Robb Koch is a USA tech journalist focused on laser engravers and other tech tools. He delivers concise, insightful reviews that help readers make informed decisions. Koch’s work spans the United States, Europe, and Asia, keeping users up-to-date on the latest advancements in the field.

Feel free to reach out to me at i.robbkoch@gmail.com.