Hello friends, today we solve a very common problem of 3D printing lovers by solving the wrong empty resin print bed! I remember being there, and it’s depressing to remember. But not to worry, I got your back. I learned a few things along the way that might help with some troubleshooting for everyone else struggling as I did. So let’s continue on to determine the root cause.

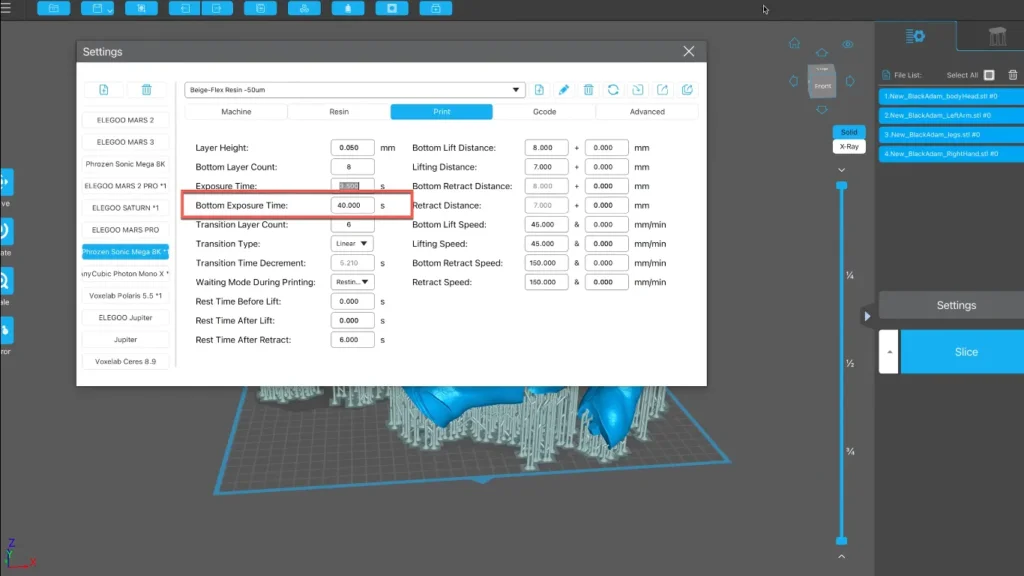

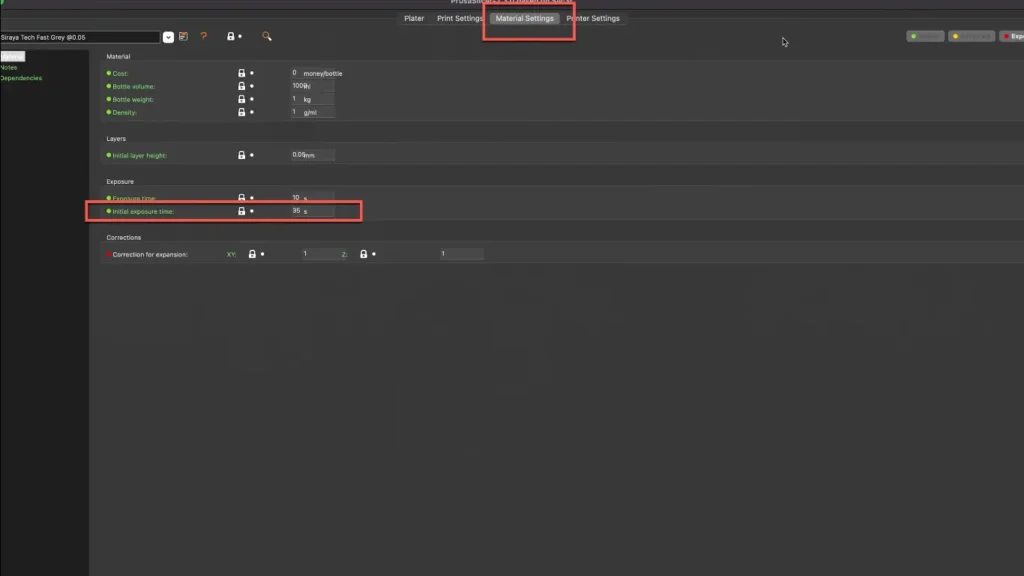

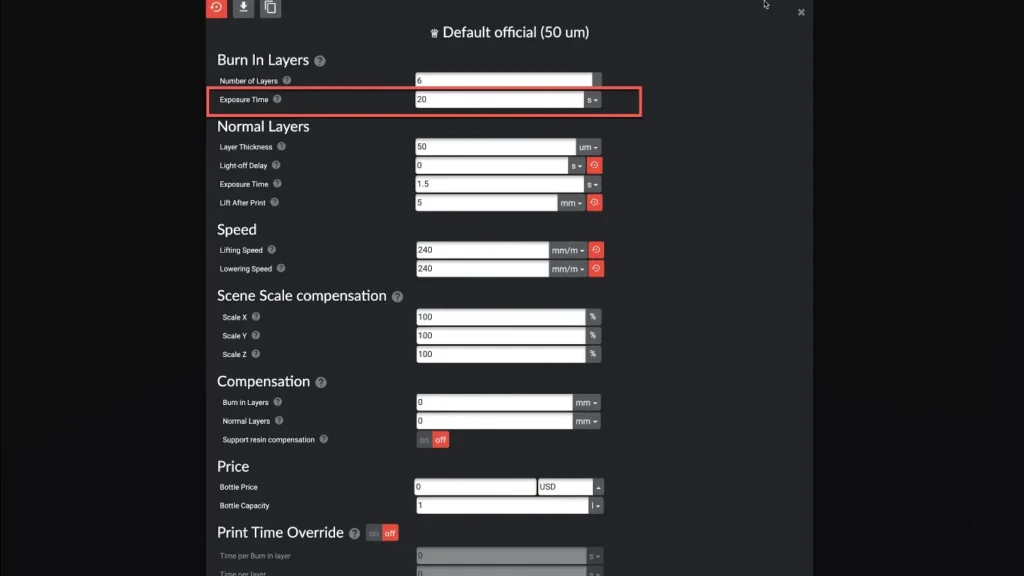

Exposure Settings Gone Wild

If you’re not seeing anything on your build plate, your exposure times might be too long or too short. Let’s figure out the best settings:

- Overexposure: If you’re cooking that resin for too long, it might be curing completely before the next layer even gets a chance. Result? A hollow print or nothing at all!

- Underexposure: On the flip side, if you’re not giving that resin enough UV love, it won’t cure properly. You’ll end up with a weak structure that falls apart faster than my New Year’s resolutions.

What to do? First off, check your resin manufacturer’s guidelines. They usually know their stuff! Then, start experimenting. Adjust those exposure times bit by bit and see what happens. Pro tip: Use a small test print to dial in those settings before you go all out on a massive model.

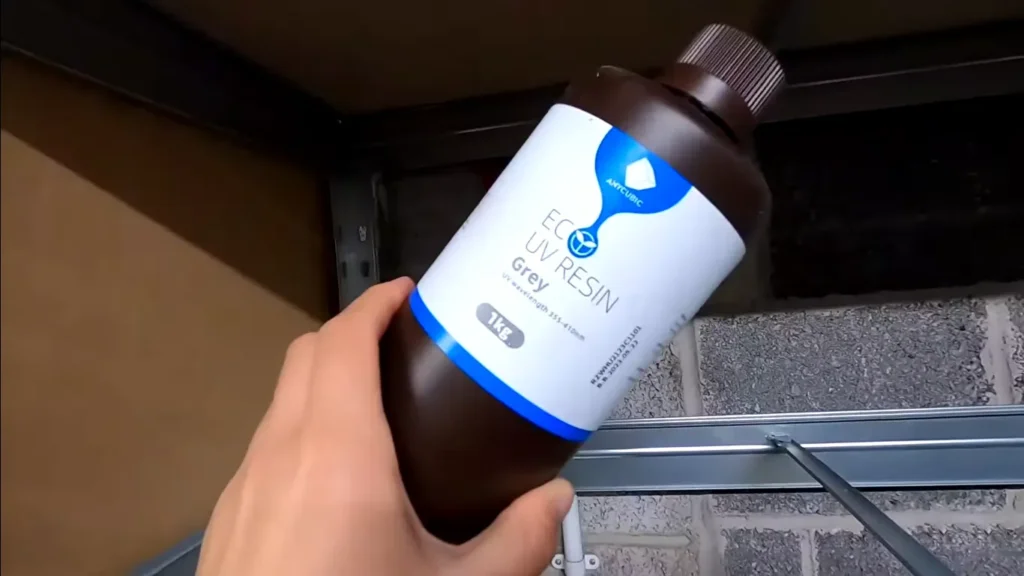

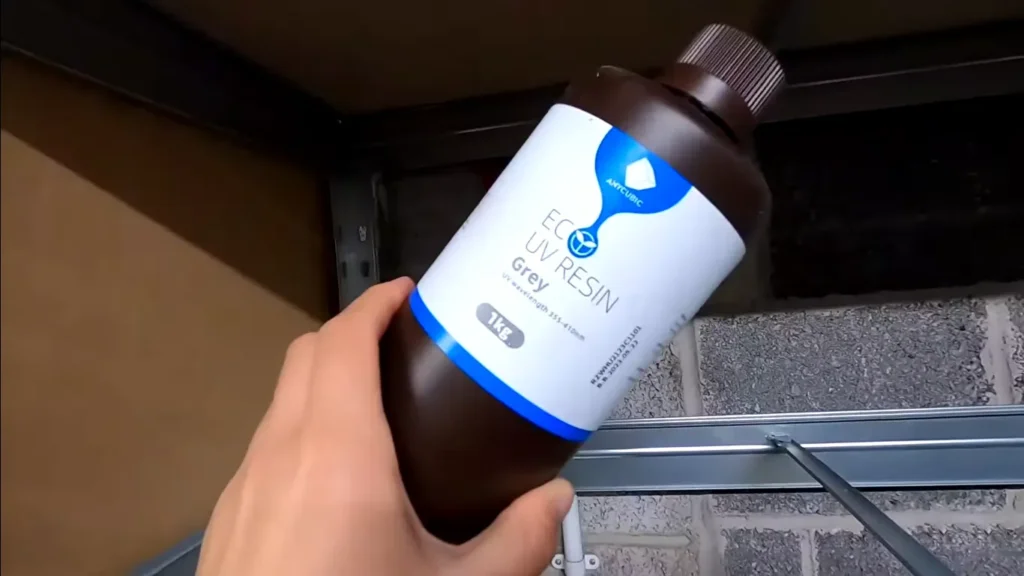

Resin Quality – The Silent Killer

Alright, let’s talk about resin quality. It’s easy to overlook, but boy, can it cause some headaches!

- Old resin: Just like that milk in the back of your fridge, resin can go bad. If it’s past its prime, it might not cure properly.

- Contaminated resin: If you’ve got bits and pieces floating around in there, your prints are gonna suffer.

The fix? Always check the expiration date, store your resin in a cool, dark place (treat it like a vampire!), and filter it regularly. Trust me, your printer will thank you.

The Leveling Game

Remember playing with those little bubble levels as a kid? Well, it’s time to channel that energy into leveling your build plate. An uneven build plate is like trying to print on a moving surface.

- Uneven leveling can cause the resin to not stick where it should, leaving you with a big fat nothing on your plate.

Solution? Follow your printer’s leveling instructions to the letter. And don’t just set it and forget it – check that level regularly, especially if you’ve bumped or moved your printer.

Stick It to Me – Build Plate Adhesion

Sometimes, your resin just doesn’t want to play nice with the build plate. It’s like trying to get peanut butter to stick to the roof of your mouth… wait, bad example, that always sticks!

- Poor adhesion means your print might detach mid-process, leaving you with resin soup instead of a cool model.

What can you do? Try using a thin layer of adhesive on your build plate. Clean that plate thoroughly between prints – no one likes a dirty dance floor! And if you’re feeling adventurous, experiment with different build plate materials. Some just work better than others.

Hardware Hiccups

Alright, sometimes it’s not you, it’s the printer. Hardware issues can be a real party pooper.

- UV light on the fritz? LCD screen throwing a tantrum? These can stop your resin from curing faster than you can say “failed print.”

If you suspect a hardware issue, give your printer a good once-over. Look for any obvious damage. If you’re having trouble, contact the manufacturer or a tech genius for assistance.

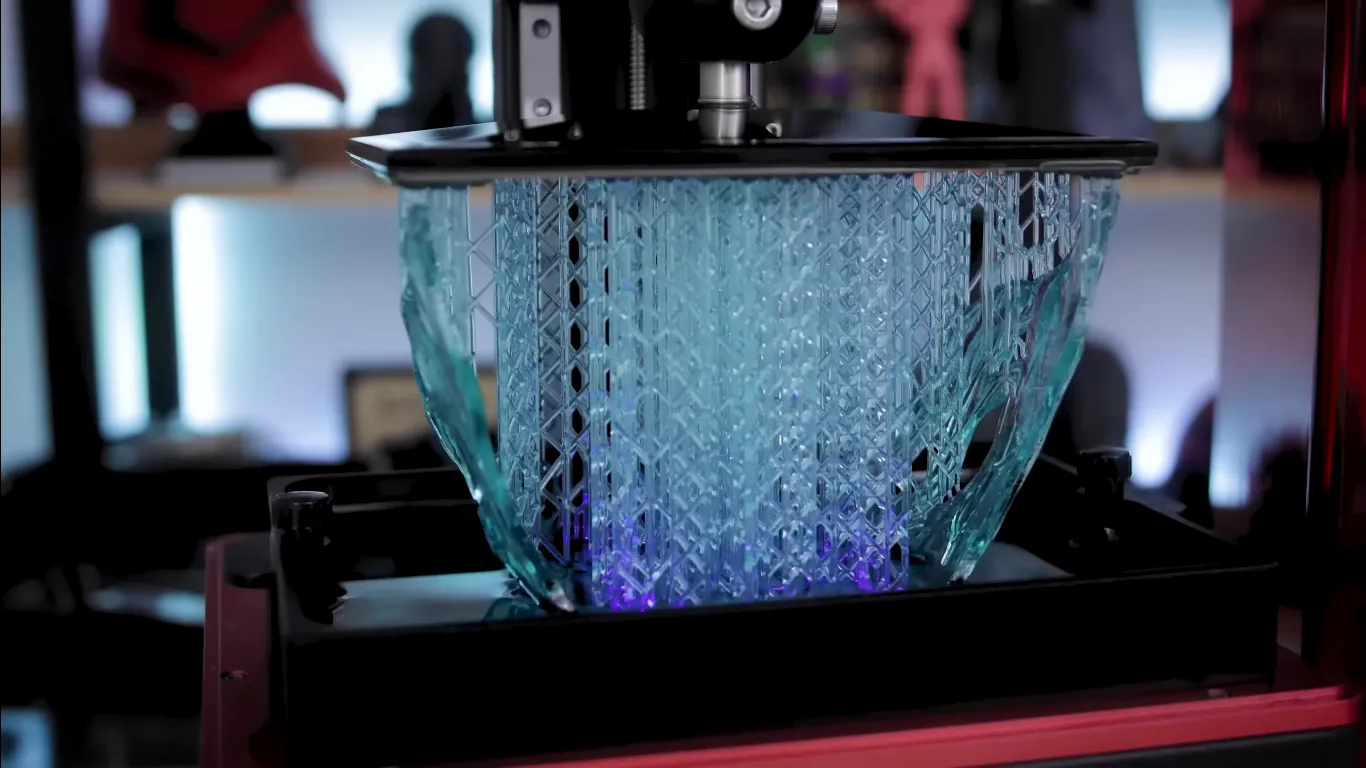

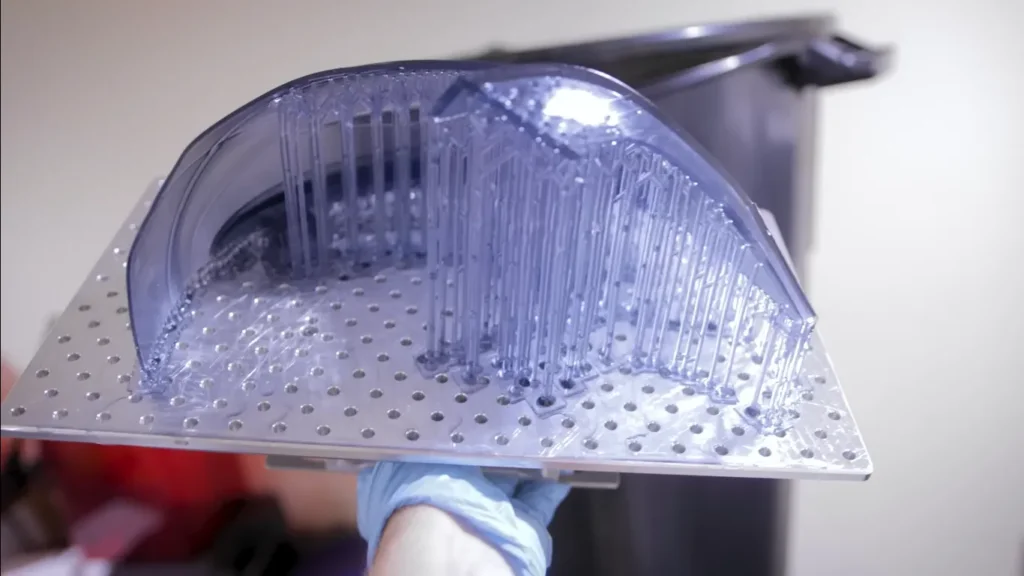

FEP Film Issues

Oh boy, how could I forget about the FEP film? This sneaky little component can cause all sorts of trouble!

- If your FEP film is cloudy, stretched, or damaged, it can seriously mess with your prints.

- Sometimes, cured resin bits can stick to the FEP, causing future prints to fail.

What to do? Give that FEP a good once-over before each print. If it’s looking worse for wear, it might be time for a replacement. And if you spot any cured resin stuck on there, here’s a neat trick:

Pour a thin layer of resin into the vat, then run an exposure test. This will create a solid sheet of cured resin that you can peel away, taking those stubborn bits with it. Just be gentle – you don’t want to puncture that FEP!

Resin Temperature

I can’t believe I forgot to mention this! Resin temperature is super important, folks.

- If your resin is too cold, it gets thicker and might not flow properly.

- Too warm, and it might cure too quickly or become unstable.

The fix? If you’re in a cooler climate, try wrapping a fermentation belt around your resin vat. For plastic vats, a space heater nearby can do the trick. Aim for a consistent temperature – your resin will thank you!

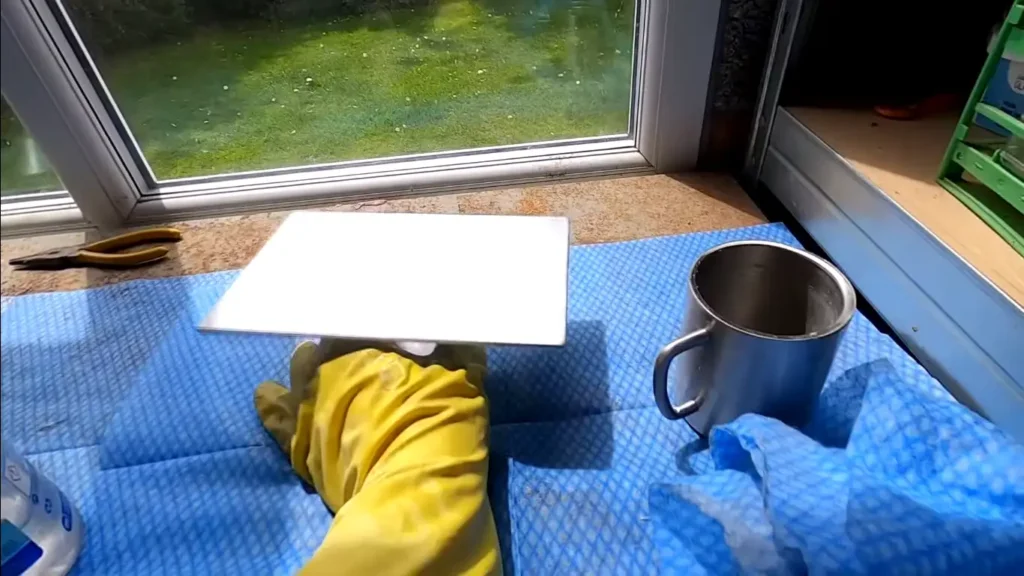

Sunlight Exposure

Here’s a rookie mistake I should’ve mentioned: exposing your printer or resin to sunlight. Big no-no!

- Exposure to sunlight can initiate the curing process of your resin, causing different types of print errors.

Treat your printer like a vampire – keep it away from sunlight at all costs! Find a nice, shady spot for your setup.

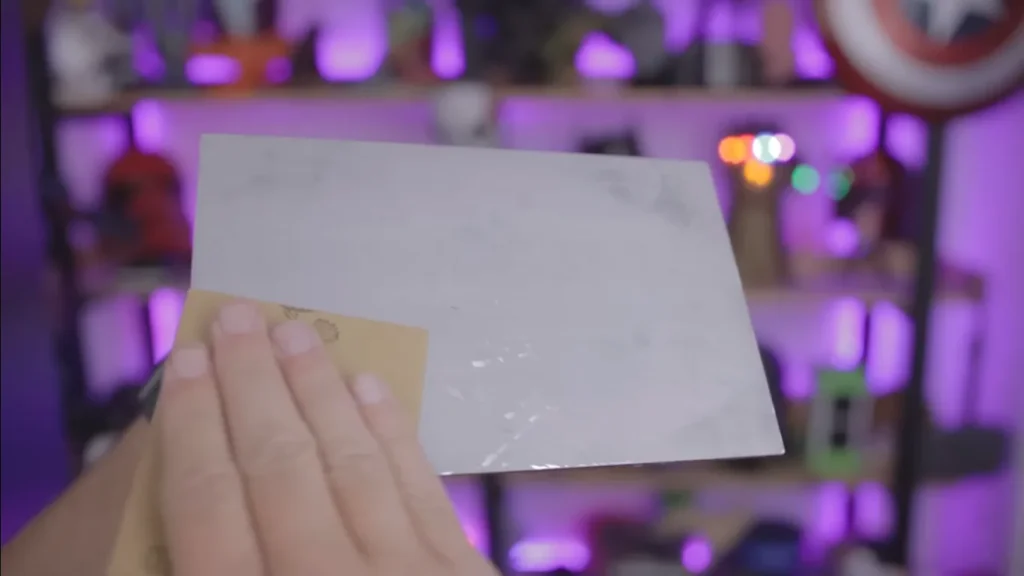

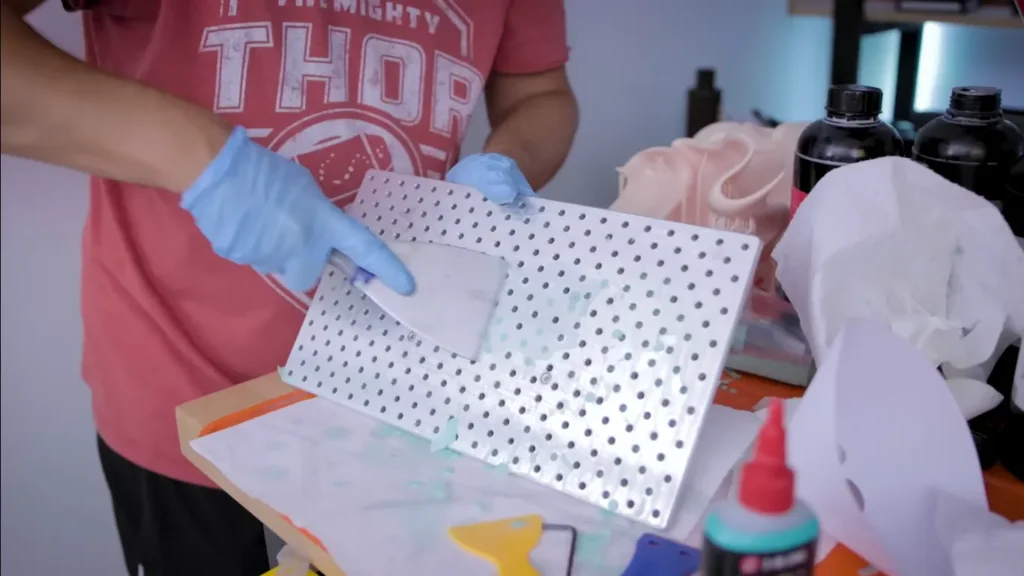

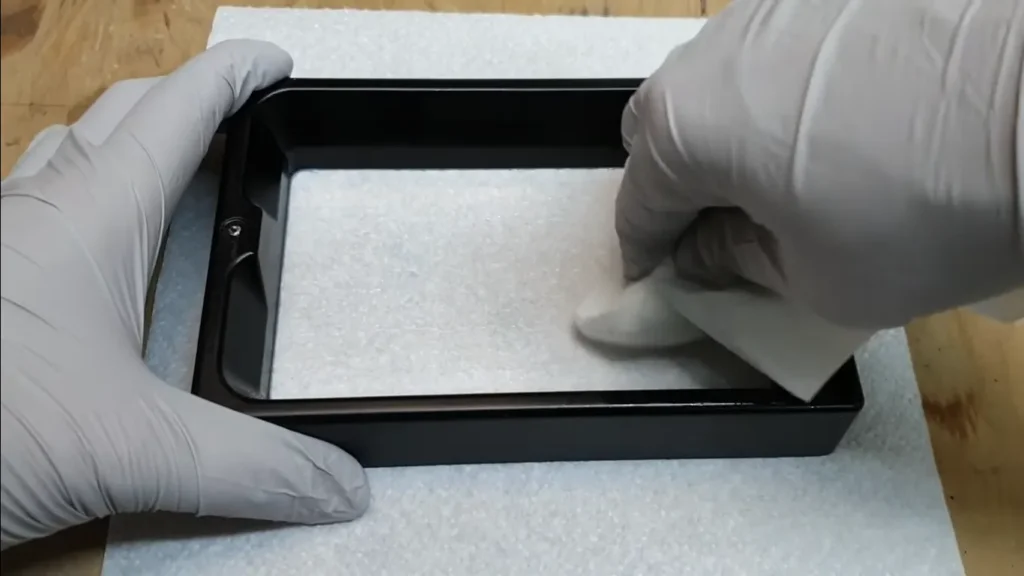

Build Plate Cleaning

While I discussed this briefly, a clean build plate is absolutely necessary for good prints.

- After removing a print, always clean your build plate thoroughly with IPA (isopropyl alcohol) and a shop towel.

- Avoid using IPA on your FEP film though – it can cause clouding over time.

Checking for Screen Issues

Sometimes, the problem isn’t with the resin or settings at all – it could be your printer’s screen.

- Run an exposure test without the vat in place. If the test pattern isn’t visible, check the screen or UV light for issues.

In this case, reach out to the manufacturer or a technician.

Resin Mixing

One final tip: Always ensure your resin is thoroughly mixed before printing, particularly if it has been sitting for some time.

- Gently stir the resin in the vat before starting a print to ensure all components are well mixed.

Bonus Round: Environmental Factors

Did you know your printer can be as picky about its environment as a cat? Temperature, humidity, even air quality can mess with your prints. Keep your printer in a stable environment – no sudden drafts or temperature swings!

And don’t forget about your slicer settings! Ensure that all settings are accurately configured for your specific printer and resin. This is crucial, just like verifying the recipe before baking a cake.

Show your printer some love! Regular cleaning and maintenance can help it run smoothly and prevent future problems.

There you have it, everyone! We’ve just explored the puzzling mystery of vanishing resin prints. 3D printing is both artistic and technical. Don’t let initial setbacks discourage you. Keep trying new things, keep learning, and soon you’ll be producing fantastic prints like a seasoned pro!

Got any questions? Hit me up in the comments. And hey, if this guide helped you out, don’t forget to give it a thumbs up! Happy printing, and may the resin gods smile upon your future endeavors!

FAQs

How often should I level my build plate?

Great question! You don’t have to level your build plate each time you print, but it’s smart to check it often. I recommend checking it about every 5 to 10 prints or if you see any sticking problems. Always re-level if you’ve moved the printer or bumped it. Remember, a well-leveled plate is like a good foundation for a house – it makes everything else work better!

Can I leave resin in the vat between prints?

Absolutely! In fact, I’d recommend it. It’s a good idea to avoid emptying and cleaning your vat after every print. This is a common misunderstanding. As long as there are no failed bits floating around, you can leave that resin in there for weeks or even months. Just give it a good stir before your next print to mix in any settled particles. It’s like stirring paint – mix it up, and you’re good to go!

My prints are sticking too well to the build plate. What gives?

Ah, the old “too much of a good thing” problem! If your prints are stuck tighter than a barnacle, you might be overexposing your bottom layers. Try reducing your bottom exposure time in small increments. Also, make sure you’re not going overboard with any adhesives on your build plate. Remember, we want our prints to stick, but not become one with the plate!

How do I know if my FEP film needs replacing?

Great question! Your FEP film is like the unsung hero of resin printing. Check your film for any obvious damage, like tears or deep scratches. If it’s cloudy and you can’t clean it properly, you might need a new one. Also, if you’re having a lot of failed prints and you’ve eliminated other problems, your FEP film could be the issue. When in doubt, replace it.

Is it normal for my printer to make a peeling sound during printing?

Yep, that’s totally normal! That sound is your printer doing its job, peeling each layer off the FEP film. It should sound like a gentle ‘peel’ or ‘pop’ with each layer. If it starts sounding more like a loud ‘snap’ or ‘crack’, that could indicate your FEP is too tight or your lift speed is too high.

My resin smells strong. Is that normal?

Resin also has a smell to it, but really it should not be too heady. If the smell gets you, try working somewhere with good ventilation. Always follow safety rules and wear a respirator if you’re sensitive to smells. Remember, a happy nose makes for a happy printer!

How can I prevent resin from curing in the bottle?

Good thinking! Keeping your resin fresh is key. Always store your resin bottles in a cool, dark place. To protect your resin from light, some people wrap their bottles in aluminum foil. Think of it as sunscreen for your resin! Always close the bottle tightly after using it. If you’re really concerned, store your resin in a light-proof container. Like a vampire, keep it away from light, and it’ll last much longer.

Nestor Sawayn is a U.S.-based tech journalist specializing in maker tools and creative technologies. His coverage spans 3D printers, vinyl cutters, paper printers, and laser cutters across North America, Europe, and Asia. Sawen’s articles offer concise, insightful analysis of the latest News, innovations in this space. Beyond hardware, he explores the creative potential of board games and tabletop RPGs, providing readers with a comprehensive view of both digital and analog maker trends.

Feel free to reach out to me at nestorsawayn@360techinsights.com.