The Bambu Lab X1 Carbon isn’t just another 3D printer – it’s a speed demon that’s been turning heads since its release. Now that I’ve spent over 1000 hours on the machine in six months, I’m going to reveal whether it meets all expectations.

This is not a printer for the faint of heart or casual hobbyist that prints a baby Yoda every once in a month. The X1 Carbon is designed for those who want to push the boundaries of what’s possible with home 3D printing. This bad boy will make your old printer look like it’s moving through molasses with its CoreXY design and carbon fiber gantry.

Bambu Lab X1 Carbon

Pros

Blazing fast print speeds

Excellent print quality

User-friendly interface and setup

Versatile material compatibility

Effective auto bed leveling

Cons

Higher price point for beginners

No wireless file storage

AMS sold separately

Limited actively heated chamber

But speed isn’t everything, right? We’ve all seen those “fast” printers that produce more spaghetti than an Italian restaurant. So, does the Bambu Lab X1 Carbon deliver on quality too? And what about all those fancy features like AI-powered first layer inspection and multi-color printing?

Stay with us as we rip into the inner workings of life on an X1 Carbon. We’ll touch on everything from unboxing to how well it holds up over time. Whether you’re a 3D printing veteran looking to upgrade or a small business owner eyeing a production workhorse, this review will help you decide if the Bambu Lab X1 Carbon is worth your hard-earned cash.

Setting the Stage: Unboxing and First Impressions

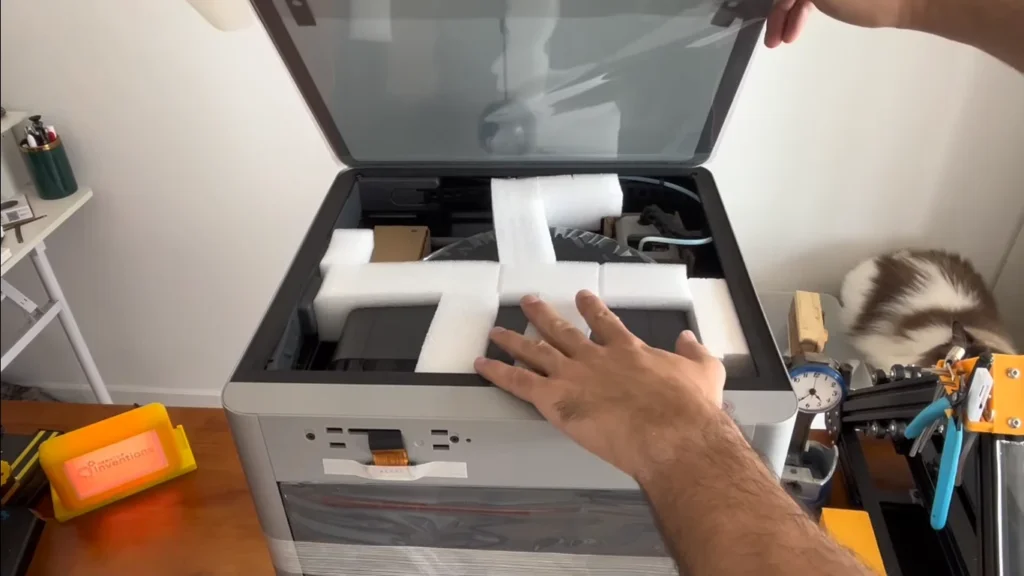

When the Bambu Lab X1 Carbon arrived at my doorstep, I was immediately struck by the careful packaging. Bambu Lab clearly put thought into ensuring their flagship printer would arrive intact. Unboxing was a breeze, with minimal assembly required – a far cry from some of the DIY kits I’ve tackled in the past.

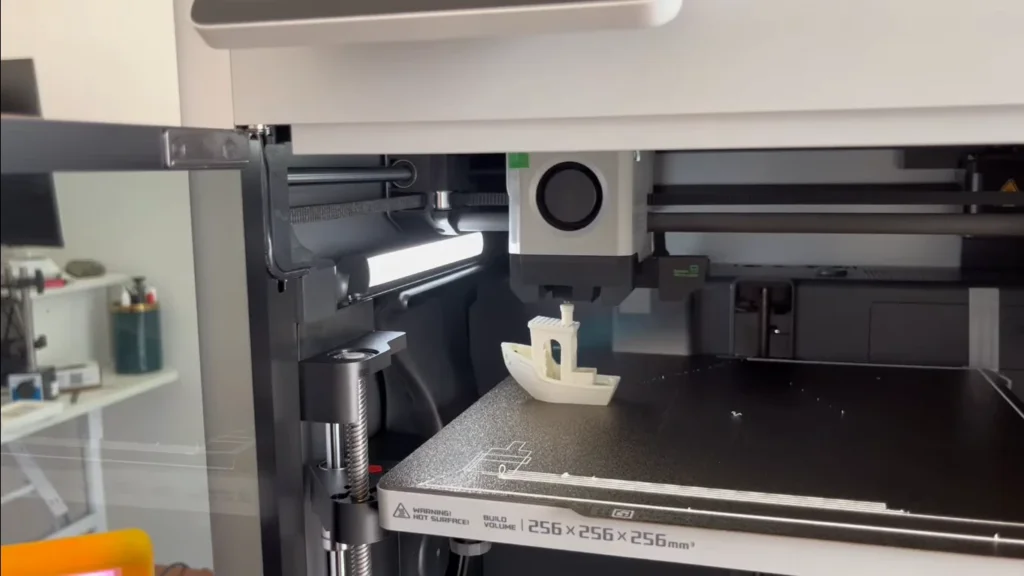

The actual printer is a proper enclosed unit with dimensions of 389 × 389 ×457. While not the smallest printer on this list, its footprint is relatively small for a whopping 256 × 256 × 256 mm build volume. I immediately noticed the full-color touchscreen on the front panel, which implied an easy-to-use experience.

Getting Started: Setup and Calibration

One of the Bambu Lab X1 Carbon’s standout features became apparent right from the start: its auto bed leveling system. As someone who’s spent countless hours fiddling with bed leveling on other printers, this was a game-changer. The printer uses a combination of lidar and analog force sensors to ensure precise leveling, and in my experience, it works flawlessly.

The initial setup process was guided by clear on-screen instructions, and within minutes, I had the printer connected to my Wi-Fi network. This allowed me to take full advantage of the Bambu Handy mobile app for remote monitoring – more on that later.

The Bambu Lab X1 Carbon comes with a flexible, magnetic build plate that’s textured on one side and smooth on the other. This versatility is great for different materials, though I found myself using the textured side most often for its excellent adhesion properties.

Speed Demon: Print Performance

Now, let’s talk about the most significant distinguishing feature of Bambu Lab X1 Carbon: its speed. Bambu Lab claims print speeds up to 500 mm/s with accelerations of 20,000 mm/s² and I can confirm these aren’t just marketing numbers. The difference in print times with my previous printers is crazy.

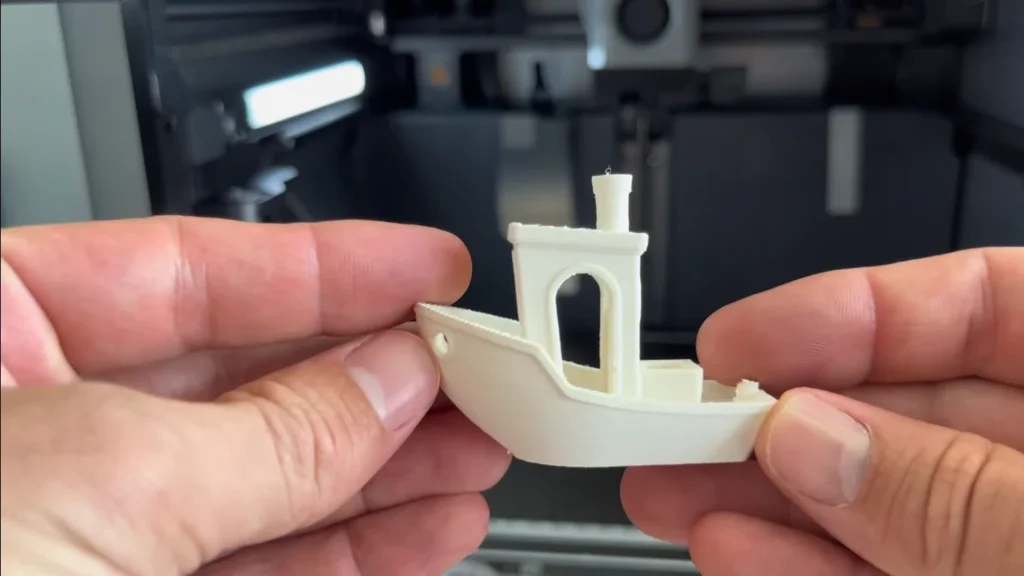

To put this into perspective, I printed a Benchy (the 3D printing community’s benchmark model) in just 17 minutes. The quality was impressive, with clean lines and minimal layer artifacts. This speed doesn’t come at the cost of quality either – I’ve consistently produced prints that rival or exceed those from my other, slower printers.

The CoreXY design, coupled with the lightweight carbon fiber gantry, allows for these blistering speeds. Even at high speeds, I noticed minimal vibration, thanks to the printer’s robust frame and vibration compensation algorithms.

Quality Where It Counts: Print Fidelity

All the speed in the world is useless if it compromises print quality. Thankfully, the X1 Carbon gets both of them right. For example, I have tried to print various working parts and detailed miniatures for the past six months — consistently having excellent results.

Its 0.4mm hardened steel nozzle works well with many materials out of the box. I have absolutely no problems with PLA, PETG and some carbon filled materials. The hotend itself is all-metal (capable of 300°C), which can also allow for some more exotic materials.

One area where the Bambu Lab X1 Carbon really shines is in its handling of overhangs and bridging. The efficient cooling system, combined with intelligent slicing profiles in Bambu Studio (their customized version of PrusaSlicer), resulted in crisp overhangs and minimal sagging on bridges.

I did notice that the top surface finish on curved surfaces could sometimes be less than perfect, particularly at higher speeds. However, this was easily addressed by tweaking settings in Bambu Studio or slowing down the top layers slightly.

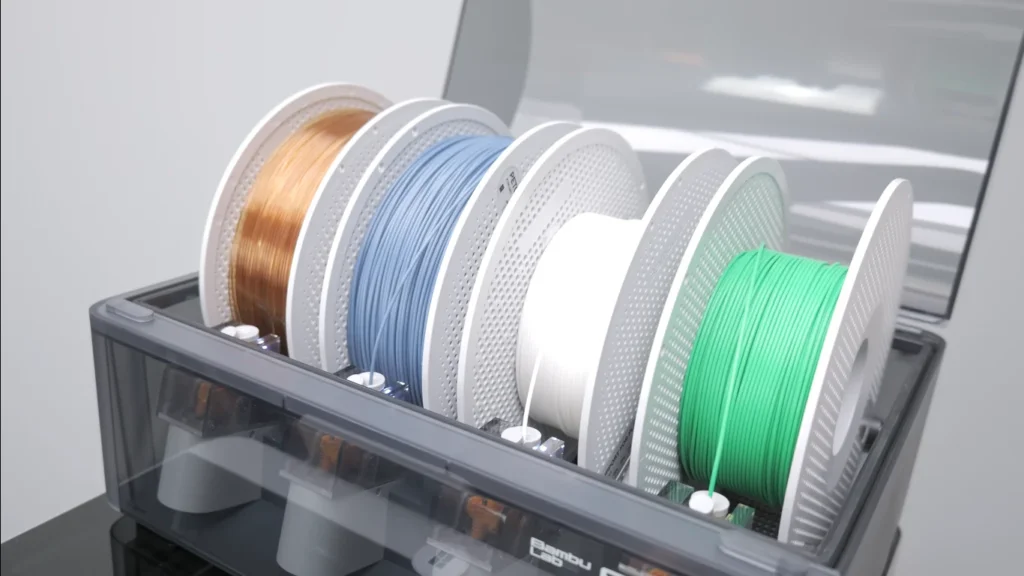

Multi-Material Magic: The AMS System

While my unit didn’t come with the Automatic Material System (AMS), I had the chance to use one extensively during a collaborative project. That makes the AMS a true revolution for multi-color and multi-material printing. Allows you to load up to four different filaments, which change as often and seamlessly as a print job requires.

The AMS works gorgeously with the Bambu Lab X1 Carbon, both hardware and software. I was particularly impressed by how well it handled purging between color changes, resulting in clean transitions and minimal waste.

For those considering the Bambu Lab X1 Carbon, I’d highly recommend springing for the combo that includes the AMS. It opens up a world of possibilities, from multi-color prints to using different materials for support structures.

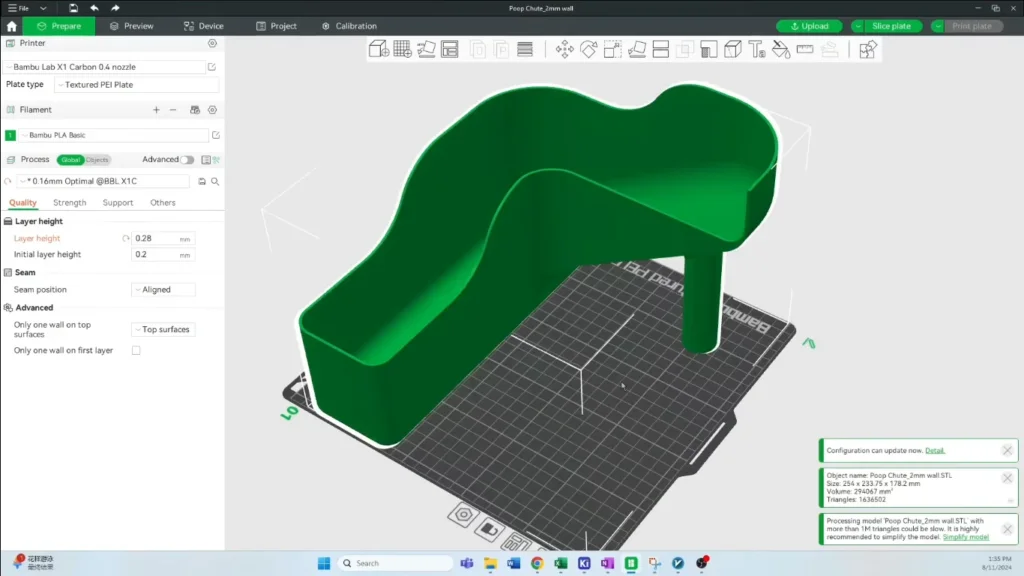

Bambu Studio: Slicing Made Simple

The X1 Carbon uses Bambu Lab’s own slicer, Bambu Studio, which is based on the popular PrusaSlicer. For those familiar with PrusaSlicer, the transition is seamless, but even newcomers will find it intuitive to use.

What sets Bambu Studio apart are the optimized profiles for the X1 Carbon. These take full advantage of the printer’s capabilities, allowing you to easily dial in the right settings for speed and quality. The software also integrates seamlessly with the AMS system, making multi-color printing a breeze.

One feature I particularly appreciate is the ability to send prints directly to the printer over Wi-Fi. Combined with the Bambu Handy app, this means I can slice a model on my computer, send it to the printer, and monitor its progress all from my phone – perfect for those long print jobs.

Hands-Off Printing: AI and Automation Features

The Bambu Lab X1 Carbon is packed with smart features that make the printing process more hands-off than ever. The AI-powered first layer inspection has saved me from several failed prints, catching issues before they become problematic.

The spaghetti detection feature, which uses the built-in camera to spot failed prints, has also proven useful. While I haven’t had many print failures (a testament to the printer’s reliability), knowing that it can automatically pause a print if things go awry provides peace of mind, especially for overnight prints.

The time-lapse feature, which automatically creates videos of your prints, is a fun addition. It’s great for sharing your creations on social media or analyzing your prints for potential improvements.

Real-World Applications: From Prototypes to Production

I put the Bambu Lab X1 Carbon through its paces over a host of projects in six months. It made rapid prototyping so much better. Iterating design quickly, and can usually print out different versions in the same day has drastically reduced my development time.

I also use it a lot for low-volume production runs of things I’m producing and selling on Etsy. Having a rock-solid reliable machine like the X1 Carbon can turn on “Set it and Forget It” mode for many day to day tasks. If I am producing a run of custom keychains or ornate decorative parts, every print will be the same high quality.

One standout project was a full-size Soldier Boy helmet from “The Boys” that I printed in under 10 hours. The large build volume of the X1 Carbon made this possible in a single print, and the result was stunning, with minimal post-processing required.

Living with the X1 Carbon: Day-to-Day Use

After the initial excitement of a new printer wore off, the Bambu Lab X1 Carbon settled into my daily workflow seamlessly. Its enclosed design keeps noise to a minimum, making it suitable for use in a home office or shared space. The built-in air filtration system, while not perfect, does a good job of reducing odors, especially when printing materials like ABS.

Maintenance has been surprisingly minimal. The direct drive extruder system has been reliable, with only one minor clog in six months of heavy use. The automated calibration routines mean I spend less time tinkering and more time printing.

My only complaint is the location of the filament spool holder at the rear of printer. This design keeps the overall footprint pretty small, but makes switching filaments a bit awkward if it’s pushed up against a wall. But this is a minor issue in an otherwise very well considered design.

Connectivity and Remote Monitoring

The Wi-Fi connectivity and Bambu Handy app have transformed how I interact with my 3D printer. It was super useful to be able to keep an eye on prints from afar, get notifications when jobs were done and even control basic printer settings just by using my phone.

I can keep an eye on print progress via the built-in camera instead of being in the same room as my printer. It does have high enough quality to see any major red flags, but for a detailed inspection you’d need to be there in person.

One feature I’d love to see in future updates is the ability to wirelessly store sliced files on the printer’s internal storage. Currently, you need to either re-slice or use an SD card for repeat prints, which can be a bit cumbersome for production work.

Material Compatibility and Versatility

The Bambu Lab X1 Carbon’s ability to handle a wide range of materials is impressive. Beyond the standard PLA and PETG, I’ve had great success with TPU, ABS, and even some carbon fiber-infused filaments. The heated bed, which can reach up to 110°C (or 120°C on 110V power), provides excellent adhesion for these more demanding materials.

One thing to note is that while the printer can handle high-temperature materials, the chamber isn’t actively heated. For large ABS prints, I found that adding a simple enclosure helped maintain more consistent temperatures and improved print quality.

The Bambu Lab ecosystem of filaments works exceptionally well with the X1 Carbon, and I’ve found their PLA and PETG to be of excellent quality. However, the printer isn’t locked to proprietary materials, and I’ve successfully used filaments from various manufacturers.

Bambu Lab X1 Carbon Specification

| Specification | Value |

|---|---|

| Build Volume (W×D×H) | 256 × 256 × 256 mm³ |

| Nozzle | 0.4 mm Hardened Steel (Included) |

| Max Hot End Temperature | 300°C |

| Filament Diameter | 1.75 mm |

| Max Build Plate Temperature | 110°C@220V, 120°C@110V |

| Max Speed of Tool Head | 500 mm/s |

| Max Acceleration of Tool Head | 20 m/s² |

| Physical Dimensions | 389 × 389 × 457 mm³ |

| Electrical Requirements | 100-240 VAC, 50/60 Hz, 1000W@220V, 350W@110V |

| Price | $1,199.00 | $1,449.00 USD (Combo) |

Long-Term Reliability and Support

The Bambu Lab X1 Carbon has been a solid workhorse for the last six months of mostly very heavy use. I have printed more than 1000 hours with it and without any major problems. The few problems I did encounter were mostly user error or easily resolved with basic maintenance.

Bambu Lab’s support has been responsive when needed, though I haven’t had to reach out often. There is an active, helpful user community around the X1 Carbon and a wealth of troubleshooting and optimization resources online.

The Future-Proof Factor

One aspect that gives me confidence in the X1 Carbon as a long-term investment is Bambu Lab’s commitment to software updates. Over the past six months, I’ve seen several firmware and slicer updates that have added features and improved performance. This ongoing development suggests that the printer will continue to evolve and improve over time.

The modular design of components like the hotend and extruder also bodes well for future upgradability. That being said, the printer is already really good and it’s always nice to know that there are ways things can get better in the future.

The Ecosystem

It’s worth noting that the Bambu Lab X1 Carbon operates within a semi-closed ecosystem. While this ensures compatibility and streamlines the user experience, it does mean you’re somewhat tied to Bambu Lab for consumables and replacement parts.

The good news is that Bambu Lab seems committed to supporting their products. Replacement parts are easily found and cheap. The downside, though, is that you can’t just slot off-the-shelf parts in here and do it yourself nearly as easily as with other open-source printers.

Value Proposition: Is It Worth the Investment?

The Bambu Lab X1 Carbon Combo (which comes with the AMS) is priced at $1,449 keeping it in the high-midrange of 3D printers for consumers. I’ve had to six months now and I can safely say that it is very much worth the price for anyone who wants quick, clear turn-a-rounds.

For hobbyists just dipping their toes into 3D printing, there are certainly cheaper options available. However, for enthusiasts, small business owners, or anyone looking to maximize productivity, the Bambu Lab X1 Carbon offers exceptional value. The time saved on faster prints and reduced setup and maintenance can quickly offset the initial investment.

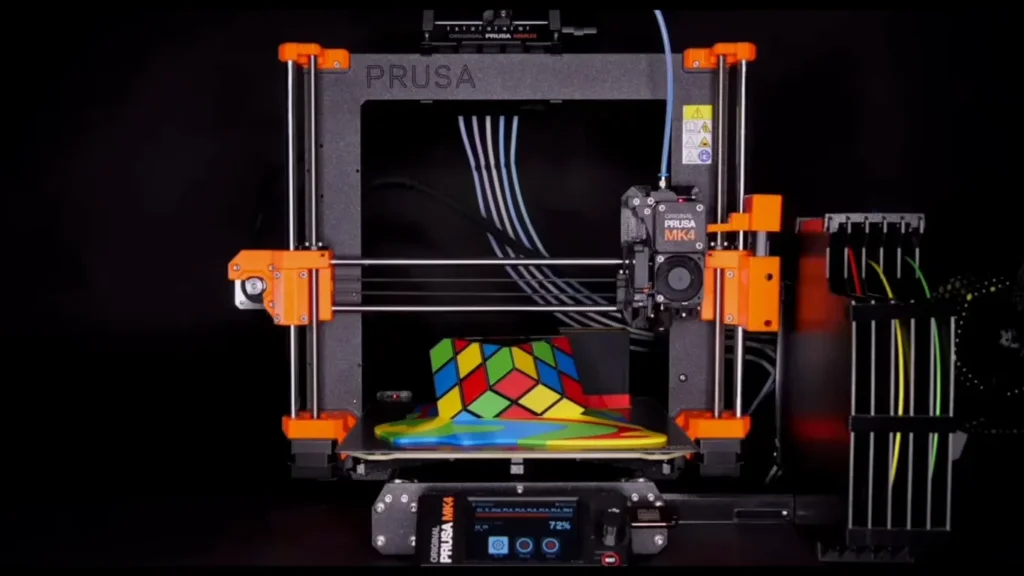

Comparing with Prusa MK4

The Bambu Lab X1 Carbon comes out swinging with its CoreXY design and impressive specs. We’re talking about a 500 mm/s maximum speed and a whopping 20,000 mm/s² acceleration. That’s some serious speed demon action right there. Plus, it’s got that fancy Automatic Material System (AMS) for multi-color printing, which is pretty cool if you’re into that sort of thing. The X1-Carbon also boasts a 7 μm Lidar resolution for precise bed leveling and a spaghetti failure detection system – because who hasn’t had a print turn into a pasta dish, right?

On the other side of the ring, we’ve got the Prusa MK4, the latest iteration of Josef Prusa’s workhorse printer. While it might not have the raw speed of the X1-Carbon, it’s no slouch either. The MK4 has doubled its print speed compared to its predecessor, thanks to some fancy Input Shaper and Pressure Advance tech. It’s also got that sweet Nextruder extruder that can handle everything from basic PLA to tricky flexibles. The MK4’s big selling point is its ease of use – we’re talking plug-and-print simplicity here, folks.

Each of the machine has a strong suite, and it could come down to which one you appreciate most. The Bambu Lab X1 Carbon is all about speed and new bells, whereas the MK4 relies on reliability first followed by ease of use, Prusa’s long-term support record and constant improvements. The X1 Carbon might be for the techy who wants the best, while the MK4 could suit an entry-level buyer or one just looking for a reliable workhorse. Either way, both of these machines are pushing the boundaries of what desktop 3D printers can do, and that’s pretty exciting stuff.

Final Thoughts

After six months of pushing the Bambu Lab X1 Carbon to its limits, I can confidently say this printer is the real deal. It’s like the sports car of the 3D printing world – fast, sleek, and turns heads, but it comes with a price tag to match.

At $1,199 for the basic model and $1,449 with AMS as a bundle it’s not exactly inexpensive. However if speed, performance or quality are important and price is no object then the X1 Carbon delivers. The amount of time you will save on faster prints and less tuning can quickly pay for the initial investment, especially if you are having to 3D parts all day everyday.

Is it perfect? Not quite. The lack of wireless file storage is a head-scratcher, and the AMS being sold separately feels a bit like buying a car and finding out the steering wheel is extra. But these are minor gripes in the grand scheme of things.

There are popular alternatives for those new to 3D printing or who do more laser cutting. However, if you are an ambitious 3D printing professional and want a machine that can stand up to your high standards then the place of X1 Carbon must be on top in your wishlist.

The Bambu Lab X1 Carbon is a look at what the future of 3D printing could hold. This thing has raised the standard for what a home 3D printer can do and now I just want to see how others respond. If you can afford it and aren’t messing around with speed (or quality), the X1 Carbon may just end up being a game-changer for you.

FAQs

Can Bambu X1C print carbon fiber?

Yes, the Bambu Lab X1 Carbon can print carbon fiber-infused filaments. You can get excellent carbon fiber-infused NylonX prints on your Bambu Lab X1 Carbon 3D printer. The printer’s hardened steel nozzle and all-metal hotend make it capable of handling abrasive materials like carbon fiber-infused filaments. For best results, follow tips and tricks from experienced users, such as those provided by MatterHackers, to start making strong, functional parts on this high-speed 3D printer.

What is Bambu Lab X1 carbon?

The Bambu Lab X1-Carbon is a high-speed desktop 3D printer that utilizes two sets of independent sensors and an algorithm to measure the nozzle height relative to the bed. It features lidar and analog force sensors for redundant bed leveling, AI-inspected first layer, and advanced printing capabilities.

How fast is Bambu Lab X1 Carbon print?

The Bambu Lab X1 Carbon has the ability to achieve a maximum print speed of 500 mm/s, and a top acceleration rate of up to 20,000 mm/s². Which is why this one of the fastest consumer 3D printer available, without being another high-speed printing machine.

Does Bambu X1 have a camera?

Yes, the Bambu Lab X1 Carbon As a camera is available The camera enables users to remotely monitoring 3D prints and record time-lapse videos of their printer as it progresses.

How does the Bambu Lab X1 Carbon work?

The Bambu Lab X1 Carbon uses a CoreXY motion system controlled by two stepper motors. These motors work together to move the printhead, with each motor connected to an independent belt. This system allows for high-speed, precise movement of the printhead.

What is the maximum height of Bambu X1 Carbon?

The Bambu Lab X1 Carbon has a maximum print size of 256 mm x 256 mm x 256 mm. This cubic build volume allows for relatively large print projects. The printer is capable of a layer height as fine as 0.05 mm, enabling high precision in prints.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.