The Bambu Lab P1P is a high-speed Core XY 3D printer that offers blazing 500mm/s print speeds while maintaining quality. With its customizable “naked” design, user-friendly features, and multicolor printing capability, it’s a powerful choice for enthusiasts. Despite some limitations like ABS printing challenges, the P1P’s performance and innovation make it a standout option in the $499 price range for those prioritizing speed and precision in desktop 3D printing.

Pros and Cons

Like any printer, the Bambu Lab P1P has its strengths and weaknesses. Let’s break them down: ⭐⭐⭐⭐

| Pros ✅ | Cons 📛 |

|---|---|

| ◈ Blazing fast print speeds ◈ Excellent print quality, even at high speeds ◈ Simple and effective auto bed leveling ◈ Abundant presets in the slicer for easy setup ◈ DIY custom side panels for personalization ◈ Optional 4-color AMS for multicolor printing ◈ Compatibility with a wide range of materials | ◈ Open design limits ABS printing capabilities ◈ Relatively high price point compared to some competitors ◈ Can be noisy at full speed ◈ Reliance on proprietary replacement parts ◈ AMS unit wastes filament during color changes ◈ Spool holder feels like an afterthought |

The Bare Essentials

At first glance, the Bambu Lab P1P looks like it’s missing something – because it is. There are no side panels included with this printer, so it looked shockingly naked. But don’t let that fool you. In fact, the absence of panels is a feature not a bug. By not including a custom side panel, Bambu Lab is cleverly passing the torch to its customers (not dissimilar from many IKEA products) in terms of creativity and DIY spirit of the 3D printing community.

Despite its stripped-down appearance, the P1P retains premium features that set it apart from the competition. Auto bed leveling, input shaping, a PEI-coated flex plate, linear rails, and a self-cleaning tool head are all present and accounted for. It’s compatible with Bambu Lab’s four-color AMS unit for multicolor prints and can be upgraded with a chamber monitoring camera and light.

Bambu Lab P1P Specs

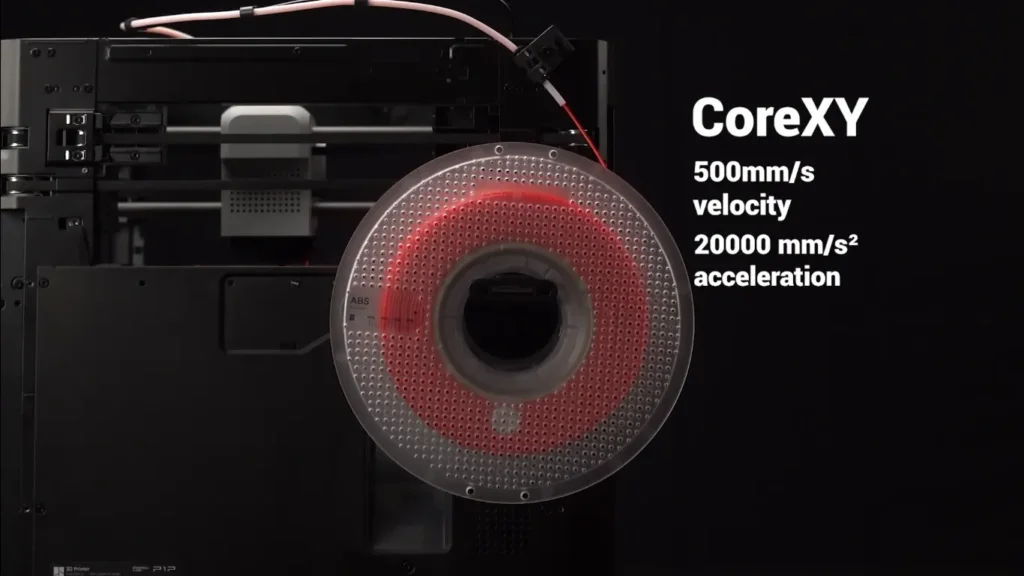

Let’s talk numbers. TheBambu Lab P1P boasts a build volume of 256 x 256 x 256 mm (10 x 10 x 10 inches), which is respectable for its class. But where this printer really shines is in its speed capabilities. Hold onto your filament spools, folks, because the P1P can hit print speeds of 500mm/s with a mind-boggling 20,000 mm/s acceleration speed. That’s twice as fast as the AnkerMake M5, making the P1P a serious contender for the speed crown.

This includes materials like PLA, TPU, ABS and PC (maximum nozzle temperature: 300 degrees Celsius). The system has a direct drive extruder and also offers .4mm proprietary nozzle. Connectivity options include microSD card, WiFi, and Bluetooth, with a simple LED screen and knob interface for on-device control.

| Specification | Detail |

|---|---|

| Machine Footprint | 386 x 389 x 458 mm (15.2 x 15.3 x 18 inches) |

| Build Volume | 256 x 256 x 256 mm (10 x 10 x 10 inches) |

| Print Speed | Up to 500 mm/s |

| Acceleration | Up to 20,000 mm/s² |

| Supported Materials | PLA, PETG, TPU, ABS, PC (up to 300°C) |

| Extruder Type | Direct drive |

| Nozzle Size | 0.4mm (proprietary) |

| Bed Leveling | Automatic |

| Build Platform | PEI textured spring steel sheet, heated |

| Filament Diameter | 1.75mm |

| Filament Runout Sensor | Yes |

| Connectivity | microSD card, WiFi, Bluetooth |

| User Interface | LED screen with knob |

| AMS Compatibility | Yes (optional) |

| Machine Weight | 9.65 KG (21.2 lbs) |

| Power Requirements | Input: 100-240V~, 50/60Hz |

Unboxing and Setup: Ready to Roll

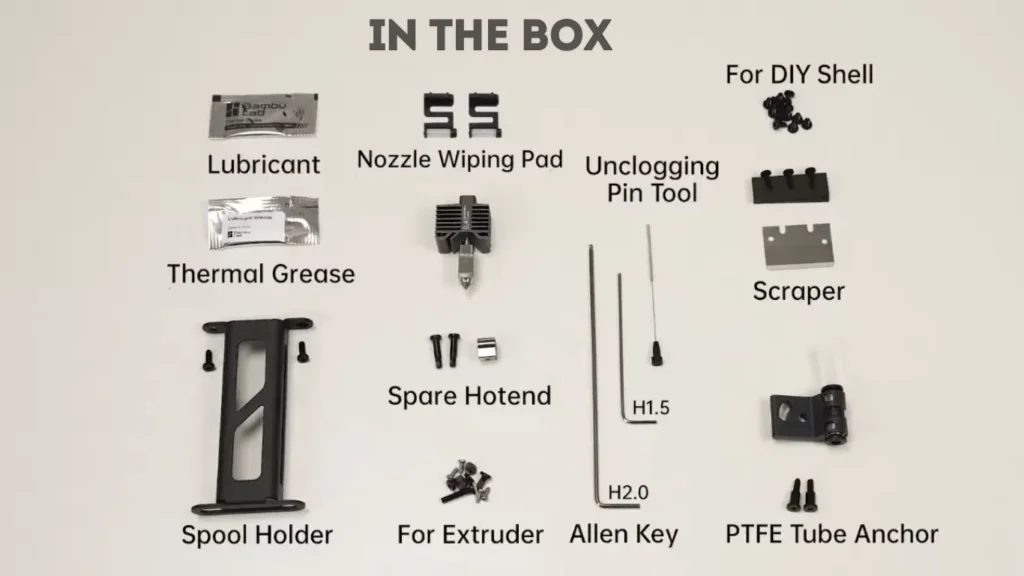

The Bambu Lab P1P comes well-equipped out of the box. Along with the printer itself, you’ll find tools for maintenance, a spare hotend, two spare nozzle wiping pads, and a microSD card. Bambu Lab has also thrown in a full-sized roll of white PLA to get you started, along with screws for attaching those DIY side panels you’ll be printing.

Assembly is a breeze, with the printer arriving mostly put together. You’ll just need to attach the reverse Bowden tube, spool holder, and control screen. The included printed guide walks you through each step, making setup a painless process even for 3D printing newcomers.

The Core XY Advantage

The Bambu Lab P1P is a true Core XY printer, a design we don’t often see at the hobby level. Like the Creality Ender 5 S1, the bed moves up and down on the Z axis. However, unlike Cartesian-style printers, the P1P uses a combination of belts to move the X and Y axes in tandem, resulting in smoother, faster printing.

It’s this Core XY design, coupled with the fast printer that allows for such a quick print without losing out on quality from the P1P. This is a testament to Bambu Lab’s engineering capabilities as well as their dedication in pushing the limits of consumer 3D printing technology.

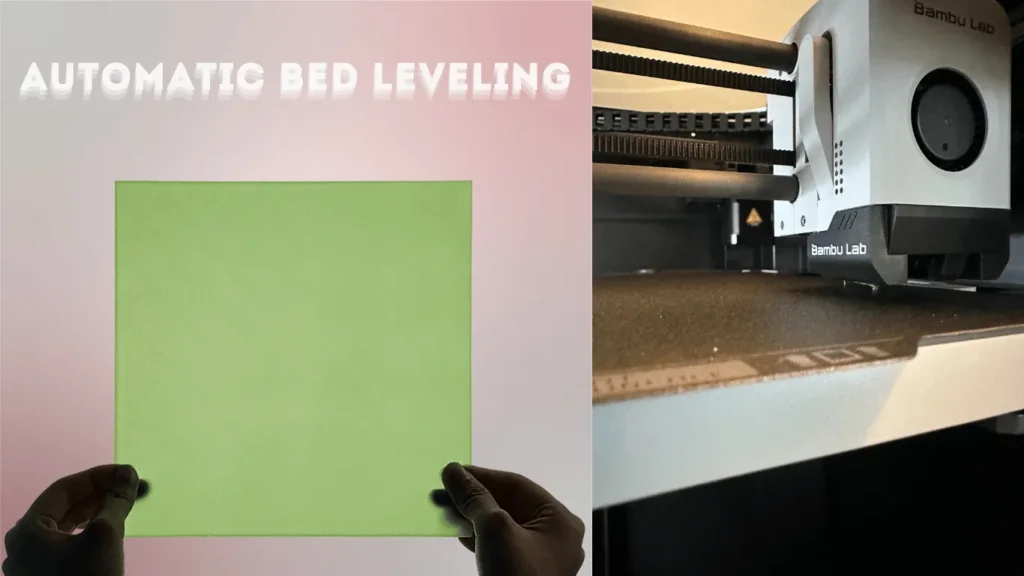

Auto Bed Leveling: A Cut Above

An interesting attribute of the Bambu Lab P1P that you do not often encounter is their proprietary auto bed leveling system. Oh, and it sounds amazing too – not just good but rather brilliant. The system not only ensures the hard-mounted print surface is flat but also sets it at the perfect Z height. In fact, there’s no way (or need) to manually adjust the Z height. Whatever magic Bambu Lab is using here, it works wonders and likely explains the need for a proprietary hotend.

Speaking of proprietary parts, it’s worth noting that all of the P1P’s components are custom and need to be purchased directly from Bambu Lab. While this might raise concerns about long-term maintenance and upgrades, the company’s web store seems to cover every part imaginable, from thermistors to belts. At least users won’t be left wondering if third-party parts will fit.

The Hotend Situation: A Double-Edged Sword

It has an all-metal hotend and uses a life-tested, 4mm stainless steel nozzle. And things start to get weird (or annoying, depending on your point of view), because the nozzle cannot be replaced a la carte. This means you will have to replace the whole hotend instead. Want to use a .6mm or .8mm nozzle? You’ll need to buy the entire hotend with that nozzle attached.

Before you start grumbling, I have some positive news. The cost of these hotends is affordable $9.99. For stainless steel and $14.99 c. For hardened steel. Also, they are designed to replace, the fan cover is held by magnets. This approach seems unusual and you have to get used to it but in the light of the long-term utilization savings can be an outstanding factor.

The AMS Advantage: Multicolor Printing Made Easy

One of the Bambu Lab P1P’s major selling points is its compatibility with Bambu Lab’s Automatic Material System (AMS). This four-color spool feeder unlocks the ability to print in four, eight, twelve, and even sixteen colors. At $349 per unit, it’s not cheap, but it opens up a world of possibilities for multicolor printing.

The Bambu Lab slicer makes it easy to digitally paint your models with color. In our tests, we were able to quickly transform a single-color horse model into a beautifully detailed buckskin with one white sock. The resulting color print was impressive, with no bleeding between colors.

However, the AMS isn’t without its drawbacks. First, it uses a significant amount of material when cleaning out the nozzle between colors. This waste can be reduced with tuning, but it requires time and patience. Secondly, using the AMS results in slower print times. The printer needs to pause between layers to purge filament and wipe the nozzle, which can significantly increase print duration for multicolor models.

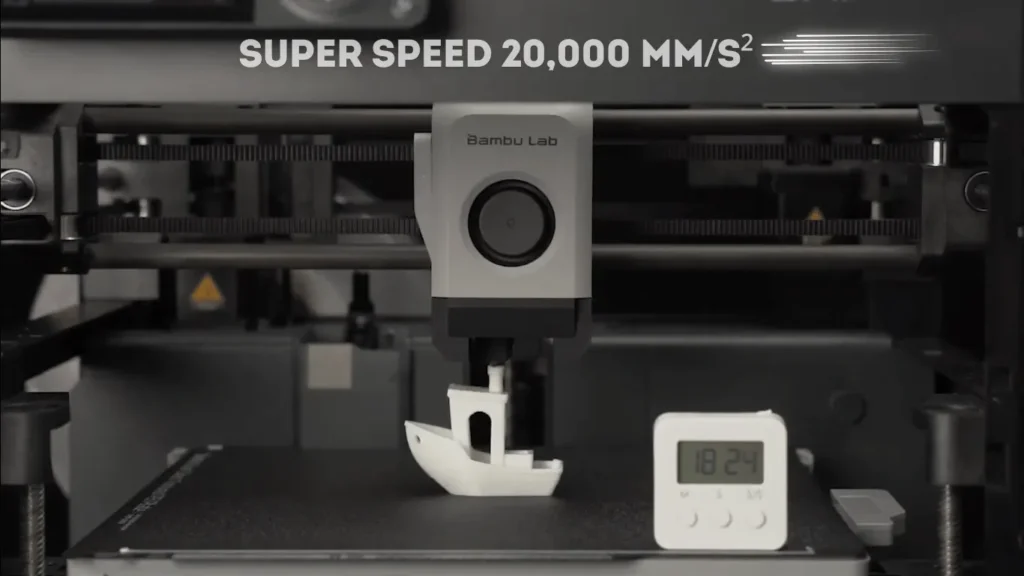

Bambu Lab P1P Speed

To really put the Bambu Lab P1P’s speed capabilities to the test, we ran it through its paces alongside some of the fastest printers we’ve tested. Using a Cali-Dragon model with similar quality settings (.2 mm layer height, 3 walls, 4 top and bottom layers, and 15% cubic infill), we compared the P1P to the Anycubic Kobra Neo, Ender 3 S1 Pro with Klipper, Anker M5 and FLSun V400.

The results? The P1P blew the competition out of the water. Here’s how the printers stacked up:

- Bambu Lab P1P: 300mm/s + Ludicrous Mode – 18 minutes

- FLSun V400: 300mm/s – 25 minutes

- Anker M5: 250mm/s – 25 minutes

- Ender 3 S1 Pro with Klipper: 150mm/s – 29 minutes

- Anycubic Kobra Neo: 65mm/s – 50 minutes

The Bambu Lab P1P’s “Ludicrous Mode” (more on that later) allowed it to complete the print in just 18 minutes, a full 7 minutes faster than its closest competitor. And remember, speed means nothing without quality – the P1P managed to maintain excellent print quality even at these breakneck speeds.

The Turbo Button: Standard, Sport, and Ludicrous Speeds

One of the Bambu Lab P1P’s more unusual features is what essentially amounts to a turbo button. Once a print is sent to the printer, you have the option to bump up the speed from standard to “sport” (124% speed) or “ludicrous” (164% speed). There’s also a silent mode that runs at half speed for those times when noise is a concern.

This feature seems to be a way to compensate for the complexity of the slicer, allowing users to stick with presets and then use the speed buttons to fine-tune print times on the fly. It’s a unique approach that adds an extra layer of control and customization to the printing process.

Slicer Software: Familiar Yet Powerful

The Bambu Lab P1P uses its own proprietary slicer suite, which is largely based on PrusaSlicer. For those familiar with Prusa’s software, the interface should feel intuitive. However, users coming from other slicers (like Cura) might face a bit of a learning curve.

Fortunately, the slicer comes with a wealth of presets for various filament types that work exceptionally well out of the box. We only found ourselves tweaking settings when we needed to make stronger parts for a separate project.

The slicer is also where you’ll program the AMS unit if you have one. It allows you to “paint” color onto your models, even if they weren’t originally designed for multicolor printing. This feature opens up a world of possibilities for customizing and enhancing your prints.

One particularly neat feature is the project manager, which allows you to save complex builds as a single 3mf file that you can easily share. These files can include several build plates, photos, and even a bill of materials, making it easy to distribute complex projects to other makers.

Bambu Lab P1P Print Quality

All the speed in the world doesn’t matter if print quality suffers. Fortunately, the Bambu Lab P1P delivers on both fronts. Thanks to its Core XY design and input shaping capabilities, the P1P manages to produce crisp, detailed prints even at high speeds.

We put the Bambu Lab P1P through its paces with a variety of materials, and it handled most with aplomb. Here’s a breakdown of our test prints:

PLA: Using Inland’s Blue/Green Silk PLA, we printed a large headphone stand. The print took 11 hours and 57 minutes at 300mm/s standard speed – compare that to the 40 hours it would take an Ender 3 S1 Pro at 150mm/s. The result was flawless, with no visible layer lines or artifacts.

PETG: We printed the P1P’s side panels in IC3D Recycled PETG in Red and Black. The printer handled PETG without breaking a sweat, maintaining its high speed and producing excellent results. The entire project, consisting of 15 pieces, took 40 hours to complete.

ABS: This is where the P1P’s open frame design shows its limitations. While it managed to print the skirt and legs of a Voron project decently, we had to partially enclose the printer with cardboard to achieve acceptable results. The printer was able to get the chamber temperature up to 30°C, which helped, but it’s clear that ABS isn’t this printer’s strong suit.

Carbon Fiber PLA: Bambu Lab provided a sample of their upcoming Carbon Fiber PLA, and the results were impressive. The prints came out impeccably smooth, with no visible ringing even on the inside of the models.

TPU: The P1P handles TPU adequately at speed, though there were a few lumps and some stringing in our test prints. We used Bambu’s own TPU 95A and its preset in the slicer, which slowed the “volumetric speed” from 21 mm³/s to 6.4 mm³/s. Running in Silent Mode, our test print took just 57 minutes to complete.

The Waste Disposal System

One peculiar feature of the Bambu Lab P1P (and other Bambu printers) is the waste chute located at the back of the machine. Even without an AMS unit, the P1P purges filament from the system before starting a print. Instead of leaving this waste on the build plate, the printer drops it through a chute at the back, where it falls onto your table or floor.

This feature, dubbed the “poop chute” by the 3D printing community, seems at odds with the otherwise thoughtful engineering of the printer. It’s surprising that a machine so well-designed in other aspects would create such a mess. Fortunately, the maker community has stepped up with numerous designs for boxes and containers to catch these filament “droppings.”

Bambu Lab P1P Error Handling

When the Bambu Lab P1P encounters an error, it tries to help diagnose the problem by issuing an error code. However, the code appears on the printer’s tiny screen as a long scroll of unhelpful numbers. More usefully, the error code also appears on the phone app and the device tab on your computer.

These codes are links to the Bambu Wiki, a knowledge base for operating Bambu printers. The Wiki provides helpful information to identify and fix problems, often with quick video tutorials. While this system is generally helpful, it would be nice to see more immediate, on-device feedback for common issues.

A Note on Safety: Thermal Runaway Protection

It’s worth noting that Bambu Lab has implemented thermal runaway protection on its machines that is slower to react than industry standards. The company has acknowledged this and plans to shorten the three-minute delay between thermistor failure and power cutoff, likely via a firmware update.

Currently, the Bambu Lab P1P has both hardware and software protections to prevent a fire should the printer’s thermistor fail. If the thermistor is disconnected, the machine will sound an alarm and cut power within 5 seconds. However, in the event of an abnormal reading – such as overheating – there is a three-minute delay before the machine turns off.

Bambu Lab has stated that this delay was set to prevent false readings during hotend maintenance. While the company’s commitment to safety is clear, users should be aware of this current limitation and keep an eye out for future updates addressing this issue.

The Verdict

The Bambu Lab P1P has been dubbed a Voron for people who don’t have the time or skill set to build one themselves, and that’s not far off the mark. It’s undoubtedly the fastest printer we’ve tested, and its ability to perform input shaping allows it to produce crisp, detailed prints at high speed. At $499, it offers exceptional value for those seeking top-tier performance.

The ability to customize the printer’s appearance with DIY panels is a fun touch that will appeal to makers who like to put their personal stamp on their equipment. However, it’s important to remember that even with panels, this is still an open-frame printer. ABS printing remains challenging without additional modifications.

For those interested in multicolor printing, the option to add a fully compatible AMS unit at half the price of an independent setup is very appealing. However, potential buyers should be aware of the increased filament waste and longer print times associated with multicolor prints.

If the P1P’s price point is beyond your budget, but you’re still after a hassle-free printing experience, you might want to consider alternatives like the $230 Neptune 3 Pro. It offers all the essential features for quality prints at a more accessible price point. For those intrigued by Delta printers and willing to spend a bit more, the Klipper-equipped FLSun V400 offers a large build area and impressive speeds, albeit with a steeper learning curve.

In conclusion, the Bambu Lab P1P is a remarkable machine that pushes the boundaries of what’s possible in consumer 3D printing. Its blistering speed, excellent print quality, and innovative features make it a standout option for enthusiasts and professionals alike. While it has a few quirks and limitations, the P1P represents a significant step forward in 3D printing technology. For those who prioritize speed and are willing to embrace its unique design philosophy, the P1P offers an exciting glimpse into the future of desktop 3D printing.

FAQs

How fast can the Bambu Lab P1P print?

The upper speed limit of the Bambu Lab P1P is a fast 500mm/s with an acceleration that tops out at m20,000 mm/s. This makes it one of the quickest consumer 3D printers on available, capable of completing prints in a fraction of time compared to standard printer.

Does the Bambu Lab P1P come with side panels?Does the Bambu Lab P1P come with side panels?

No, the Bambu Lab P1P comes without side panels, giving it a “naked” appearance. With a design like this, users can print and finally assemble own side panels which is truly amazing personal touch that you cannot find to many 3D printers.

Can the Bambu Lab P1P print in multiple colors?

Yes, the Bambu Lab P1P is compatible with Bambu Lab’s optional Automatic Material System (AMS) add-on. This allows for printing in up to four colors without manual filament changes, opening up possibilities for complex, multicolor prints.

What materials can the Bambu Lab P1P print?

The Bambu Lab P1P supports a wide range of materials including PLA, PETG, and TPU. It can also print ABS, though with some limitations due to its open frame design. The printer’s high-temperature capabilities allow for experimentation with various filament types.

Is the Bambu Lab P1P difficult to set up?

No, the Bambu Lab P1P comes mostly assembled and is designed for easy setup. The initial assembly process is straightforward, and the printer features auto bed leveling, further simplifying the setup process for users of all experience levels.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.