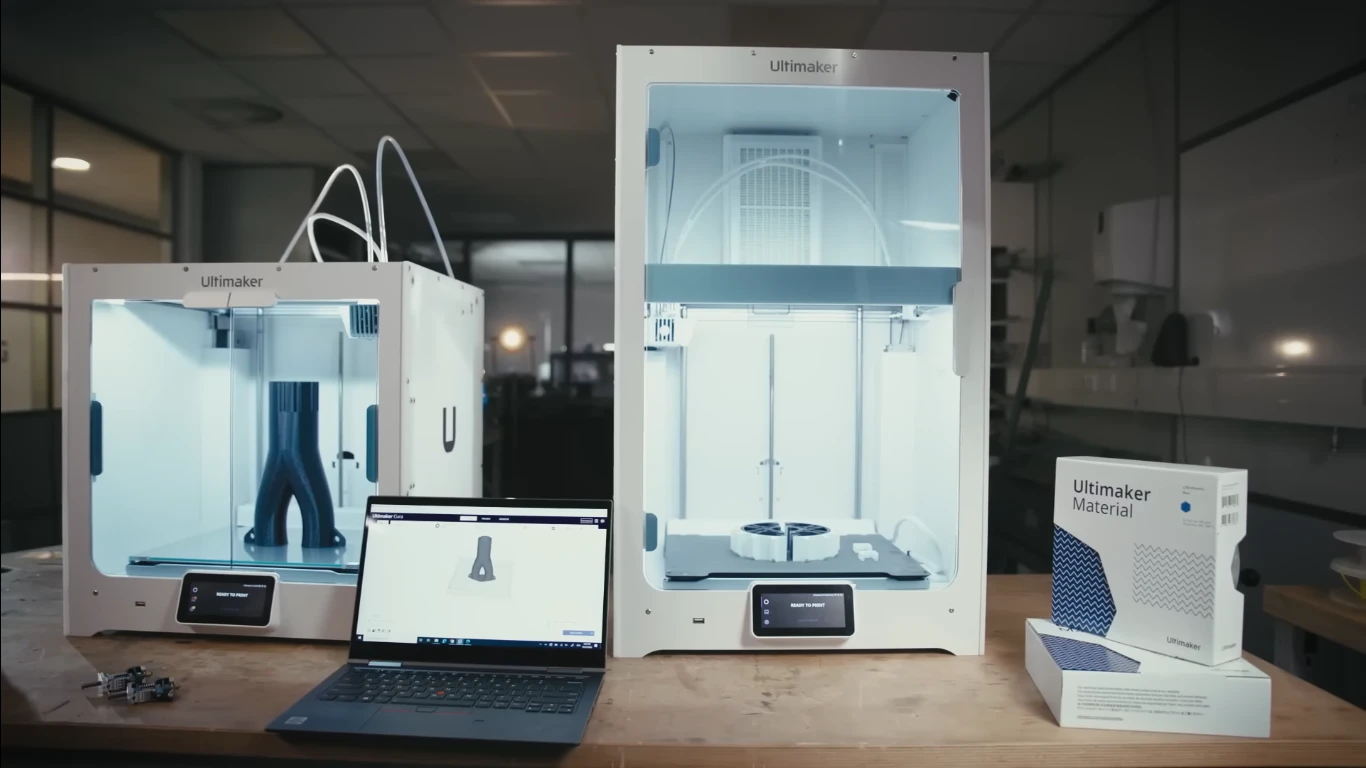

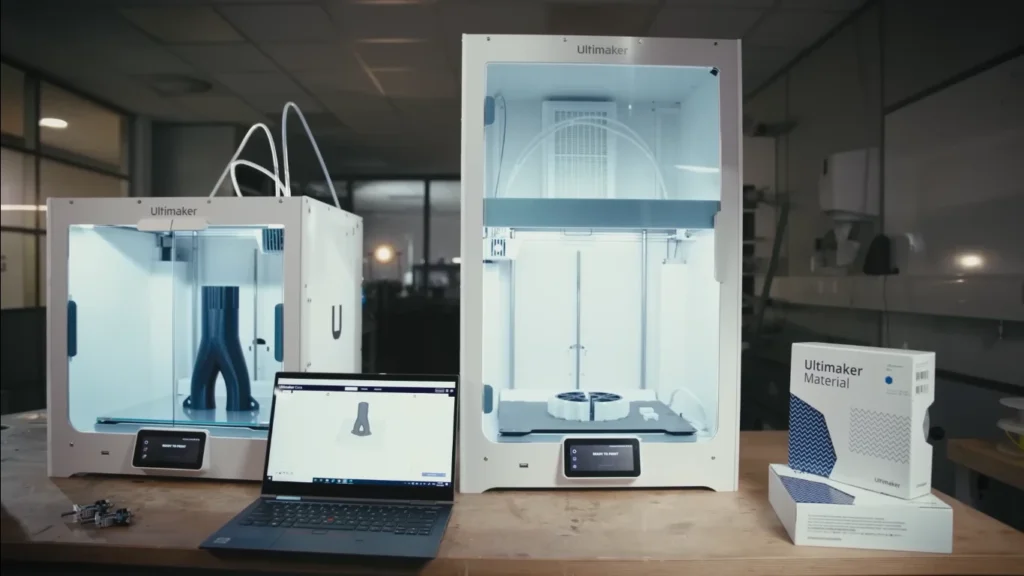

The Ultimaker S7 Pro Bundle would seem to be such an animal, filling the gap between high-end consumer models and proper industrial-grade bulk production machines. Offering a fantastic build volume of 330 x 240 x 300 mm alongside some advanced features it makes this machine an ideal candidate for professionals, small businesses and the dedicated hobbyist. An impressive watch with a lot going for it, but does it deliver in the real world. I will share my long-term review of this large 3D printing ecosystem and how it worked after using for several weeks.

Quick Overview

- Dual extrusion system for multi-material printing

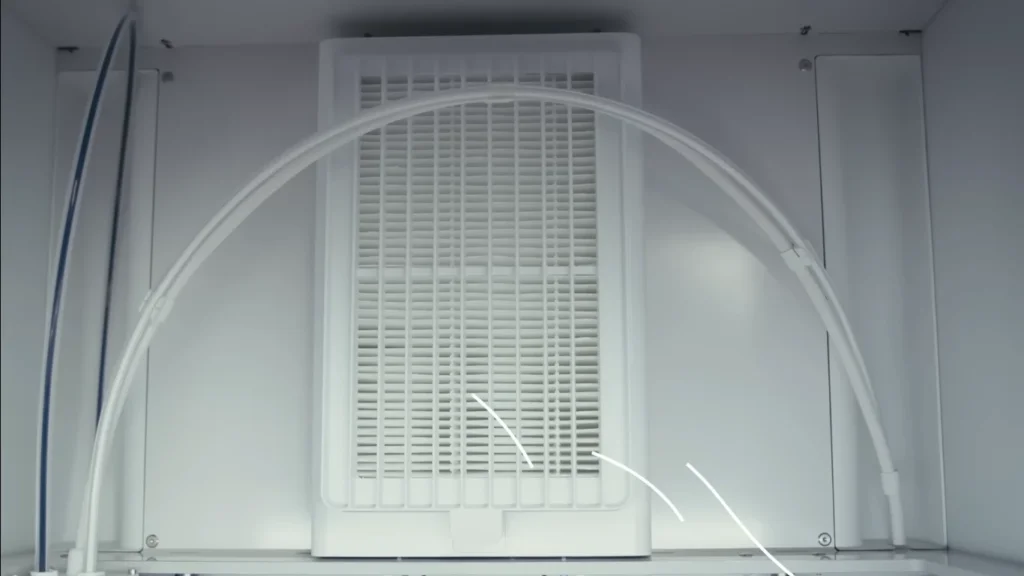

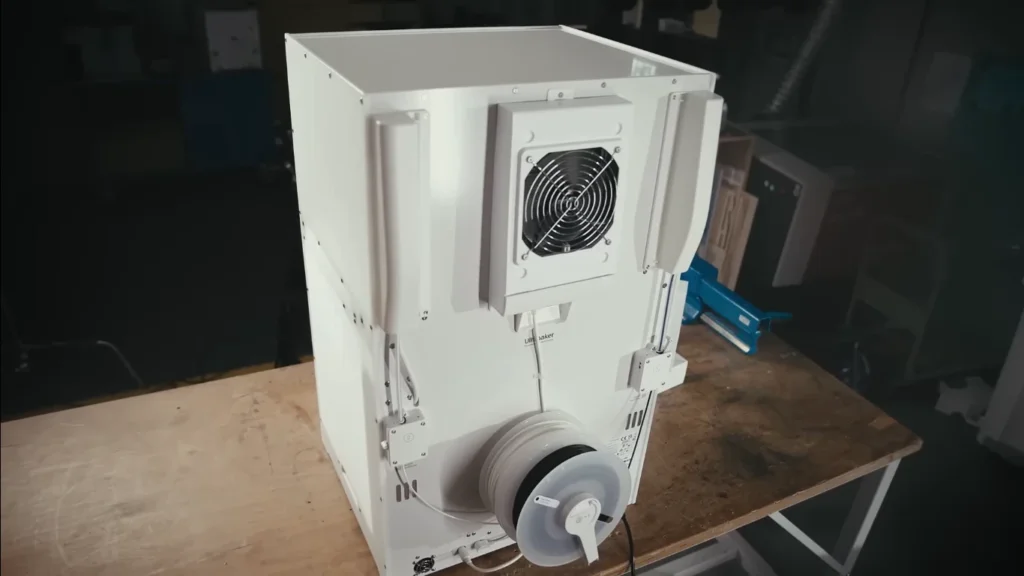

- Integrated Air Manager for clean, controlled environment

- Material Station for automated filament handling

- Large 330 x 240 x 300 mm build volume

- Flexible, PEI-coated build plate for easy print removal

- Advanced auto-leveling system for consistent first layers

- Compatibility with wide range of materials, including engineering-grade

- Remote print management via Ultimaker Digital Factory

- User-friendly interface with 4.7-inch touchscreen

- Seamless integration with Ultimaker Cura slicing software

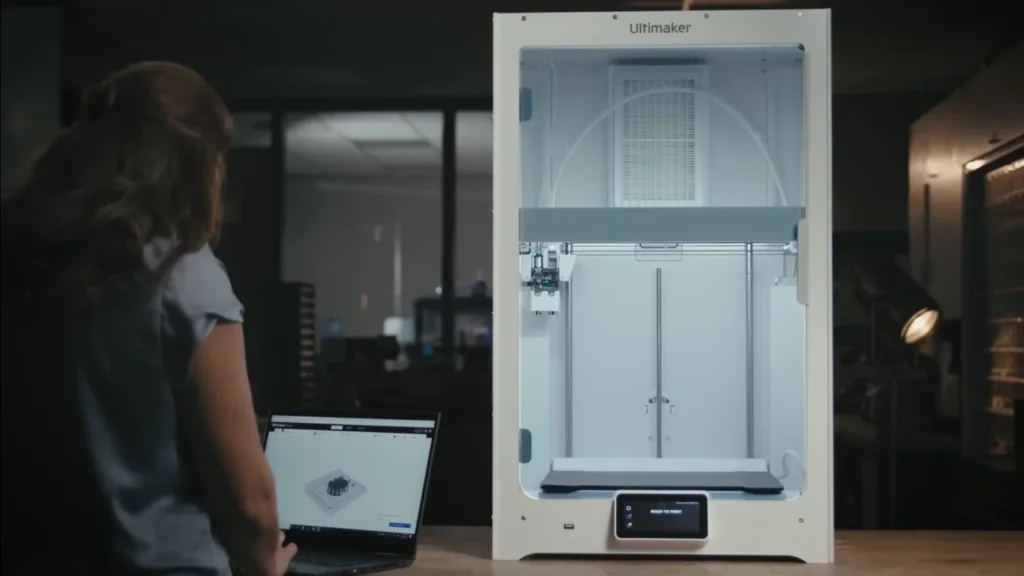

The Ultimaker S7 Pro Bundle is a striking proposition straight from the box. This sleek, enclosed design includes not only the printer itself but also incorporates an integrated Air Manager and Material Station. Although it looks overwhelming due to the specific parameters available, Ubiquiti has done an excellent job with how clear all of the parts and directions are. I had the whole system put together in under 15 minutes, ready to take on its first print.

The Ultimaker S7 Pro Bundle, offers a level of versatility that cannot go without standing out. Whether you are developing a product, designing an end-use part or producing complex model for visualization; this machine is engineered to handle all. However, competing against some very strong offerings priced at a similar level is the Ultimaker S7 Pro Bundle worth the investment? Let’s open it up and see if this 3D printing workhorse delivers what the company has promised.

First Impressions and Setup

Right out of the box, the Ultimaker S7 Pro Bundle exudes quality. The sleek, enclosed design immediately catches the eye, promising a controlled printing environment that’s crucial for consistent results. Setting up the printer was surprisingly straightforward, even for someone who’s tangled with their fair share of finicky 3D printers.

The bundle includes the Ultimaker S7 printer, the integrated Air Manager, and the Material Station. While it might look a bit daunting at first – there are quite a few tubes and components – I had the entire system up and running in about 10 minutes. The color-coded parts and intuitive design made the assembly process almost foolproof.

The Ultimaker S7 Pro is very easy to use, and this is indeed a selling point of the printer. The 4.7″ touchscreen walks you through initial set-up and, thanks to the integration with Ultimaker Digital Factory software, controlling your prints is a joy whether standing at the printer or monitoring it from somewhere else entirely.

Pros ✅

+ Exceptional print quality

+ Integrated air filtration

+ Automatic material handling

+ Large build volume

+ User-friendly interface

+ Wide material compatibility

+ Remote print management

Cons 📛

– High price point

– Large footprint

– Steep learning curve for advanced features

– Optimized for proprietary materials

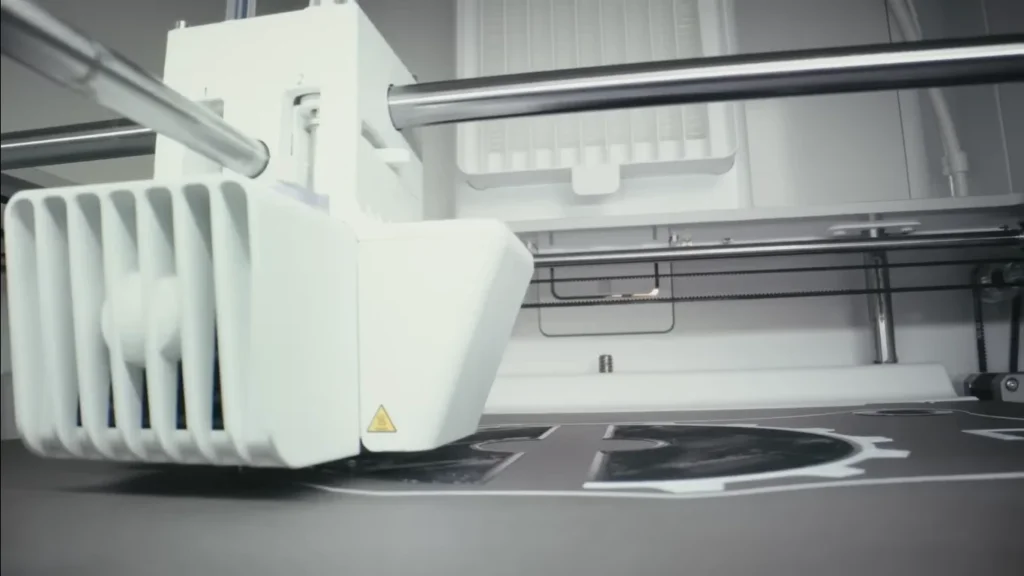

Print Quality and Performance

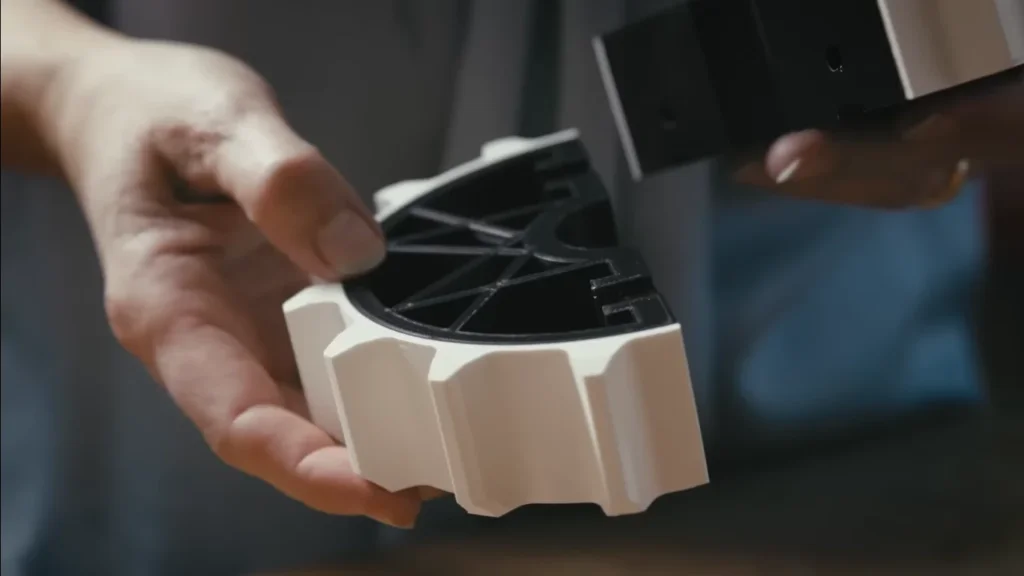

After spending several weeks working with the Ultimaker S7 Pro, I’m thoroughly impressed by its print quality. The dual extrusion system and precise movement create incredibly smooth and consistent layers.

I began with simple PLA prints to get acquainted with the machine. Even these basic prints looked professional. To really put it to the test, I tried more difficult materials like PETG, TPU, and even carbon fiber-reinforced nylon. The Ultimaker S7 Pro handled them all flawlessly.

One of the most impressive features is its ability to maintain high quality throughout long prints. I ran a 72-hour print using the Material Station to automatically switch between different colored PLA filaments. The result was perfect – no layer shifts, no inconsistencies, just a beautiful, multi-color print that looked like a factory product.

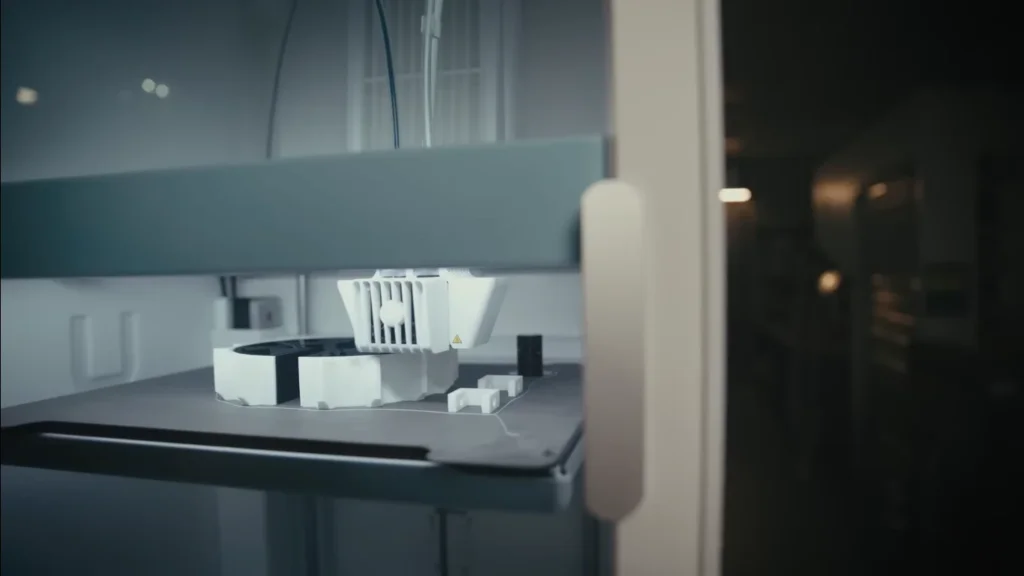

The integrated Air Manager is another standout feature. It keeps the printing area clean and controlled while also reducing noise. I could work in the same room without being bothered by fan noise or odors.

Advanced Features for Professional Use

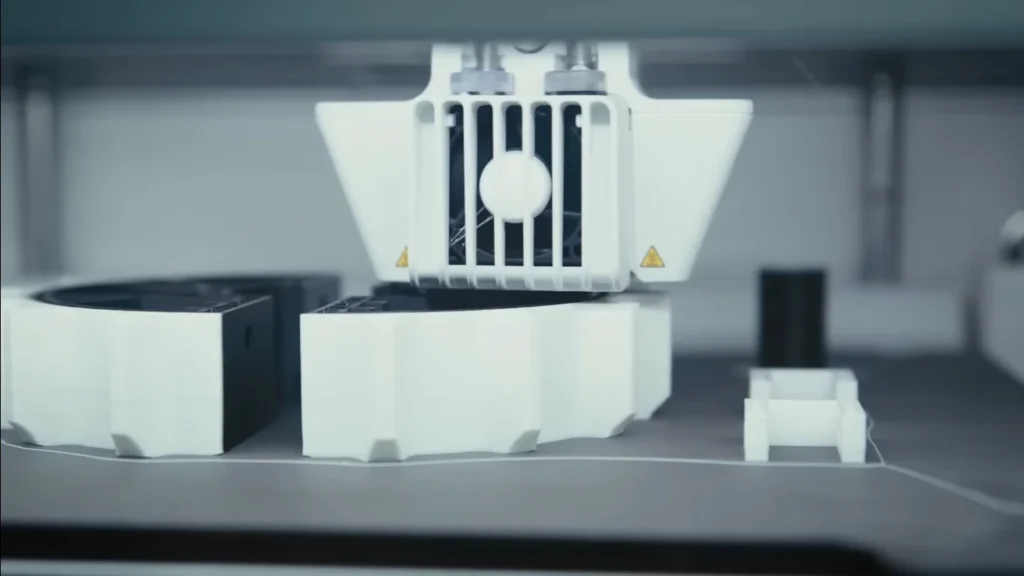

The Ultimaker S7 Pro stands out as a featured 3D printer, especially with its professional applications. A built-in self-leveling system with a tactile sensor ensures each print goes down on a level bed every time. During my tests, I never encountered a single failed print caused by bed adhesion problems, a common issue with other printers.

The flexible, PEI-coated build plate is another game-changer. Removing prints is as simple as flexing the plate, and the surface provides excellent adhesion without the need for glues or other additives. This feature alone saved me countless hours of post-processing time.

The Material Station is where the Ultimaker S7 Pro really shines for professional users. With the ability to hold up to six spools of filament, it allows for unattended printing of large, multi-material projects. The humidity control feature ensures moisture-sensitive filaments stay in prime condition, vital for consistent print quality.

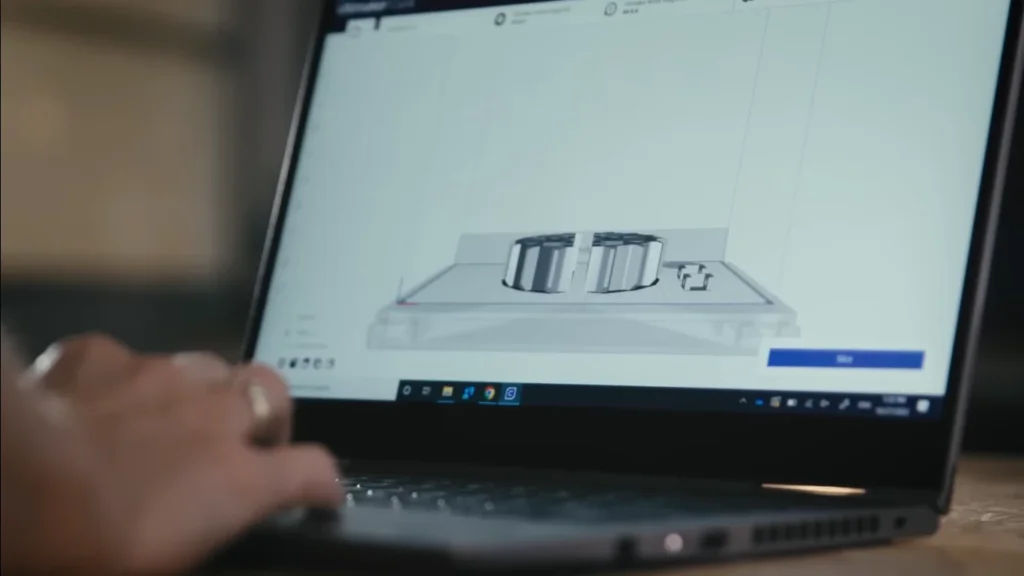

Software and Connectivity

The Ultimaker S7 Pro is delivered with the Ultimaker Cura software, one of the strongest and easiest slicing solutions on hand. The hardware integrates perfectly with the software, taking advantage of print profiles that are ideal for what the S7 can handle.

Wi-Fi, Ethernet and USB derive a full range of in-parts connectivity options. Additionally, busy professionals will appreciate the convenience of monitoring and managing prints remotely using Ultimaker Digital Factory. I found myself frequently checking in on long prints from my phone, adjusting settings on the fly when needed.

Material Compatibility and Versatility

The Ultimaker S7 Pro is incredibly versatile when it comes to materials. I was able to print with a wide variety of filaments, including the common PLA, ABS, and PETG, as well as more specialized options like TPU, Nylon, and even carbon fiber-reinforced materials.

Having dual extrusion brings a lot of benefits specially if some geometry has overhangs, makes the supports to be soluble or it is just more optimal with different material. I was particularly impressed with how well the printer handled water-soluble PVA supports, producing intricate models that would be impossible to achieve with traditional support structures.

The Material Station’s NFC recognition system automatically detects the type of filament loaded, adjusting print settings accordingly. This feature, combined with the humidity-controlled storage, ensures that you’re always printing with optimally maintained materials.

Long-Term Reliability and Maintenance

After several weeks of heavy use, the Ultimaker S7 Pro showed no signs of wear or decreased performance. The enclosed design and air filtration system keep the internal components clean, which should contribute to long-term reliability.

Maintenance is straightforward, with easy access to key components for cleaning and occasional replacement of wear parts like nozzles. The touchscreen interface provides helpful maintenance reminders and guides, making it easy to keep the printer in top condition.

Specifications Chart

| Feature | Specification |

|---|---|

| Build Volume | 330 x 240 x 300 mm |

| Layer Resolution | 20 – 200 microns |

| Nozzle Diameter | 0.4 mm (included), 0.25, 0.6, 0.8 mm available |

| Filament Diameter | 2.85 mm |

| Print Head | Dual extrusion with swappable print cores |

| Build Plate | PEI-coated flexible steel plate |

| Max. Build Plate Temperature | 140°C |

| Max. Nozzle Temperature | 300°C |

| Connectivity | Wi-Fi, Ethernet, USB |

| Air Filtration | Integrated Air Manager with EPA filter |

| Material Capacity | 6 spools (with Material Station) |

| Software | Ultimaker Cura, Digital Factory |

| Dimensions (with Air Manager) | 495 x 585 x 780 mm |

| Weight | 43 kg (95 lbs) |

| Price | $11,500 |

Comparing the Ultimaker S7 Pro Bundle to Previous Models

After using the Ultimaker S5 and S3 before, I must say that the difference when stepping up to an entire bundled package along with this form factor on something like the s7 Pro Bundle feels significant. Now the click ability Air Manager an optional add-on for the S5 is flawlessly integrated in its design. This both enhances print quality and allows for a much sleeker more confined architecture visually.

The new flexible build plate is a major improvement over the glass plates used in previous models. It not only improves first-layer adhesion but also makes print removal much easier and safer.

The upgraded print head with its anti-flood sensor and stronger closure mechanism addresses some of the minor issues that users experienced with earlier models. Throughout my testing, I didn’t encounter any of the nozzle clogging or filament feeding issues that occasionally plagued the S5.

Who Should Consider the Ultimaker S7 Pro Bundle?

Following plenty and in-depth of hands-on experience, the Ultimaker S7 Pro Bundle is most certainly meant for professional use cases or businesses who need higher-end 3D printing capabilities. Certain characteristics, such as ease of use and advanced functionality lend it to a variety of uses:

- Product Design and Prototyping : It is good at creating highly detailed prototypes for complicated geometries thanks in part to the dual extrusion system and wide material compatibility.

- Engineering and Manufacturing: The ability to print with engineering-grade materials like reinforced nylons opens up possibilities for end-use parts and tooling.

- Education: While it might be overkill for basic educational needs, the Ultimaker S7 Pro would be at home in advanced engineering labs or maker spaces where students need access to professional-grade equipment.

- Medical and Dental: The high precision and ability to print with biocompatible materials make it suitable for creating custom medical models or dental appliances.

- Architecture and Design: The large build volume and excellent surface finish quality make it ideal for creating detailed architectural models.

Potential Drawbacks

While the Ultimaker S7 Pro is impressive, but it has some drawbacks:

- Cost: This is also a serious investment at $11,500 Although the quality and functionality do justify the cost for most professionals, it might very well be too expensive for hobbyists or smaller companies.

- Learning Curve: Fairly user-friendly but the plethora of settings and features can be complex to a novice It might take a little time to use all the capabilities of printer.

- Size: The full bundle, including the Material Station, takes up a considerable amount of space. This might be a concern for users with limited workspace.

- Proprietary Ecosystem: The printer does support third-party materials as well, however its built for Ultimakers own filaments and print cores. This reduces options for users who like to play around with the variety of third-party materials.

Final Thoughts

The ultimate Ultimaker S7 Pro Bundle is available in multiple models for around $11,500 which uses the complete combo of an S7 printer unit and Material Station with Air Manager. Although this places it at the higher end of prosumer 3D printers that will be well out of reach for many, just what value you get from one depends on your requirements and usage.

The Ultimaker S7 Pro Bundle is a great value for professional, reliable 3D printing that offers flexibility and quality wherever it’s needed. With a powerful set of features – including impeccable print quality, material compatability and automatic material handling & air filtration this machine is capable of performing from rapid prototyping to even small-scale manufacturing.

However, if you’re primarily focused on basic 3D printing tasks and don’t need the advanced material handling or enclosed printing environment, there are certainly less expensive options available that might better suit your needs. It’s also worth noting that while the Ultimaker S7 Pro is incredibly versatile, there are more specialized machines that offer higher power or faster print speeds for specific applications.

Ultimately, it’s easy to recommend the Ultimaker S7 Pro for professional environments where reliability, ease of use, and print quality are paramount. Its comprehensive ecosystem approach, combining hardware, software, and materials, creates a seamless 3D printing experience that can significantly boost productivity and capabilities.

For those on the fence, consider your long-term 3D printing needs. Whether you expect to work with many different materials, have long print jobs that can be left unattended or appreciate a clean and controlled printing environment the investment in an Ultimaker S7 Pro Bundle would likely save time and even material costs for higher quality prints.

So in the end, what has Ultimaker done with their educators pricing that is so much better than anything else out there? The machine is ready to tackle virtually anything you want it to do, from basic prototypes up to complex multi-material printing. No question it will not appeal to everyone; but, if you require such functionality this thing can be a virtual beast and integration point for almost any professional design or manufacturing workflow

FAQs

How long does it take to set up the Ultimaker S7 Pro Bundle?

Initial setup typically takes about 10-15 minutes, with additional time needed for software installation and calibration.

Can the Ultimaker S7 Pro use third-party filaments?

Yes, it can use third-party 2.85 mm filaments, but it’s optimized for Ultimaker materials.

How quiet is the Ultimaker S7 Pro during operation?

With the integrated Air Manager, the S7 operates at less than 50 dBA, making it suitable for office environments.

Does the Ultimaker S7 Pro require regular maintenance?

Yes, regular maintenance includes cleaning the build plate, checking and cleaning nozzles, and replacing the air filter as needed.

Can the Ultimaker S7 Pro print with flexible materials?

Yes, it can print with flexible materials like TPU, especially when using the appropriate print core.

How does the Material Station work?

The Material Station can hold up to 6 spools of filament, automatically switching between them as needed. It also features humidity control to keep materials in optimal condition.

What is the Ultimaker S7 price?

The Ultimaker S7 price is $8,299.00.

Is the Ultimaker S7 Pro Bundle suitable for beginners?

While user-friendly, the S7 Pro Bundle is designed for professional use. Beginners may face a learning curve with its advanced features.

Can the Ultimaker S7 Pro print with soluble support materials?

Yes, its dual extrusion system allows for printing with soluble supports like PVA.

How often do I need to level the build plate?

The S7 features an advanced auto-leveling system, so manual leveling is rarely necessary. The system performs automatic adjustments before each print.

What is the Ultimaker S7 Pro Bundle price?

The Ultimaker S7 Pro Bundle costs about $11,500 with the printer plus an Air Manager and Material Station.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.