When Creality announced the Ender 3 V3 Plus, I was skeptical. Another 3D printer in the already crowded budget printer market? But after weeks of rigorous testing, I’m ready to share my honest review of this desktop manufacturing marvel. That may not make it the best 3D printer on every list, but the Ender 3 V3 Plus is definitely worth your consideration if you’re looking for a versatile machine that packs speed, precision, and ease into a small package.

Right out of the box, the Ender 3 V3 Plus is nearly assembled and ready to go. However, to truly unlock its potential, you’ll want to explore its advanced features and material capabilities. The printer offers an impressive blend of speed and precision that challenges many preconceptions about budget 3D printing.

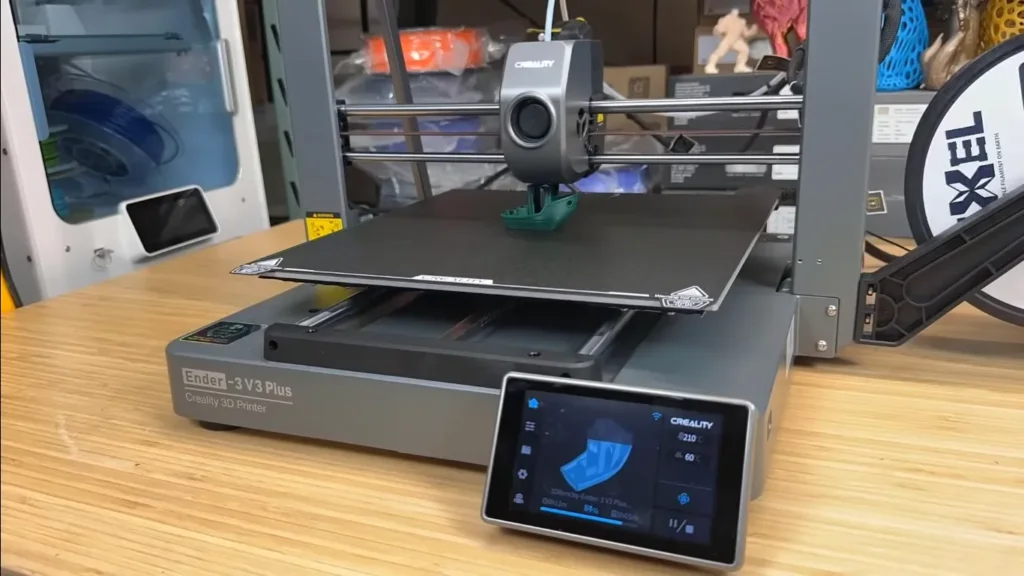

One of the standout features is the CoreXZ motion system and the intuitive 4.3-inch HD touchscreen. With the Creality Print software and Creality Cloud app, consumers enjoy an integrated ecosystem that is tailored to a simplified 3D printing experience. Well, let’s get into the details and see if the look is worth the hype.

Ender 3 V3 Plus

Pros

Incredibly fast setup

Impressive print speeds

Excellent print quality

User-friendly interface

Cons

Ringing at high print speeds

Open frame limits ABS use

First Impressions: Not Your Average Budget Printer

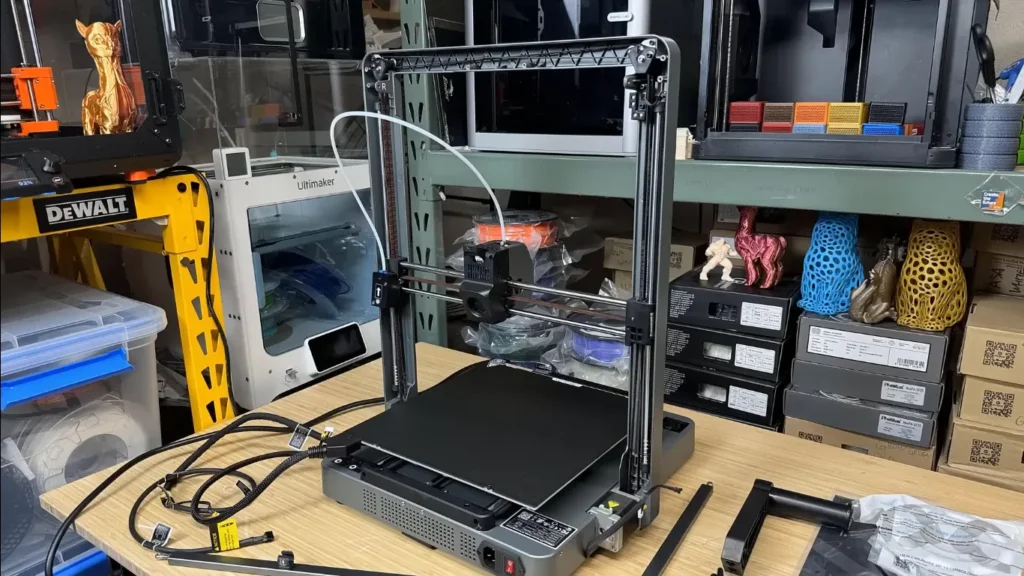

The moment I unboxed the Ender 3 V3 Plus, something felt different. Gone are the days of complicated assembly and frustrating setup that plagued earlier Ender models. This printer arrives almost entirely pre-assembled, with a modular design that makes setup feel more like unboxing a smartphone than wrestling with a complex machine.

My total setup time? Just about 20 minutes. And that includes connecting to Wi-Fi, calibrating the bed, and preparing for the first print. For context, my previous Ender 3 Pro would have consumed an entire evening with cable management, manual bed leveling, and troubleshooting.

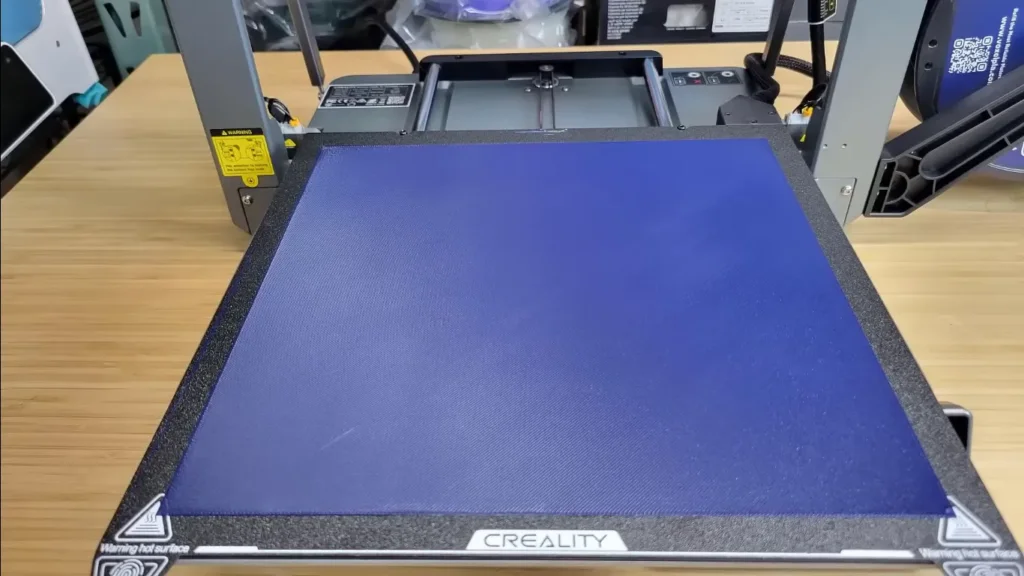

The printer’s aesthetic has also received a significant upgrade. Creality has ditched the utilitarian look for something more refined – soft curves, a die-cast aluminum frame that feels solid, and a sleek profile that looks more like a piece of modern tech than a workshop tool. At 410 × 445 × 577 mm, it’s surprisingly compact for a printer offering a substantial 300 × 300 × 330 mm build volume.

Performance: Speed Meets Precision

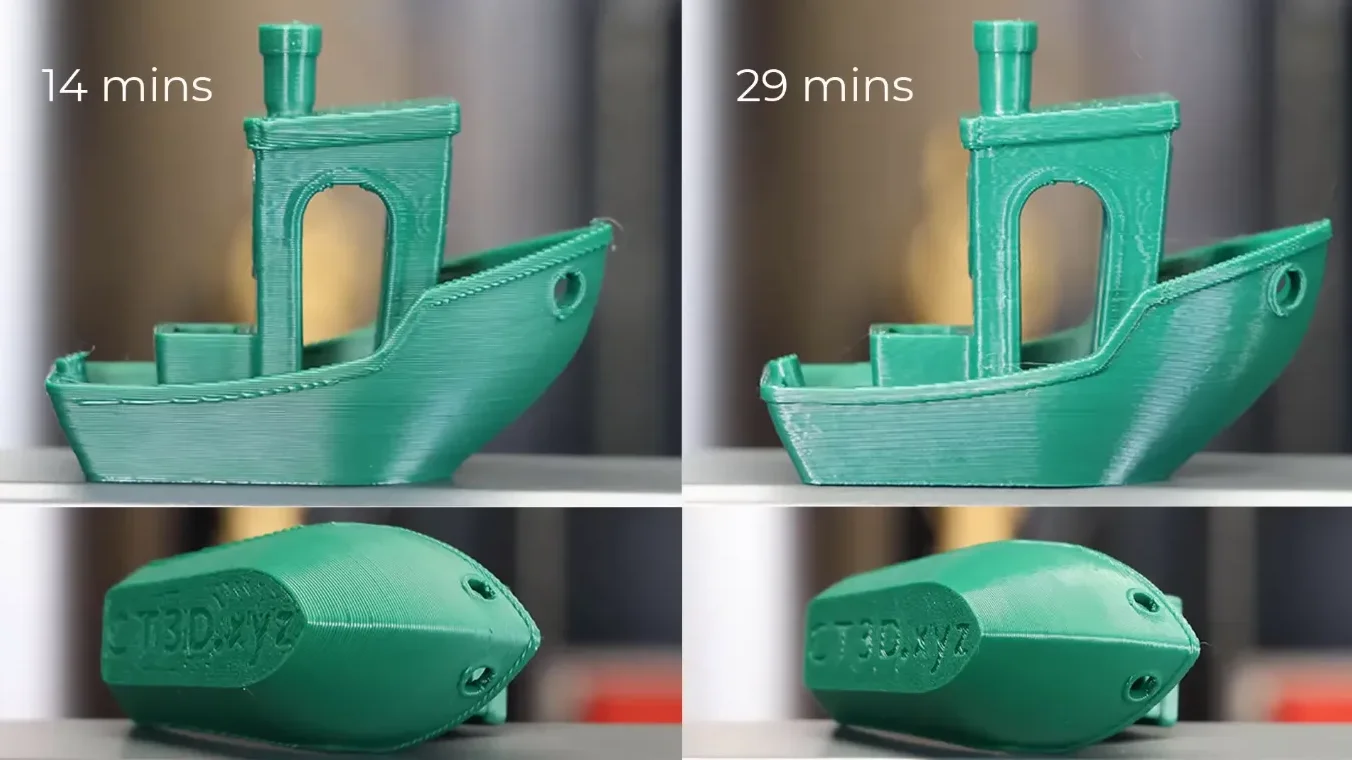

The headline feature is undoubtedly speed. Creality claims up to 600 mm/s printing speeds, which sounds almost ludicrous for a printer in this price range. In practical testing, I found the sweet spot closer to 300-400 mm/s, where print quality remained consistently excellent.

My benchmark test – the classic 3D Benchy – went from a typical 45-minute print to just 14 minutes. More impressively, the quality didn’t suffer. Layer lines were smooth, details crisp, and dimensional accuracy spot on. The CoreXZ motion system, with its dual Y-axis motors, genuinely makes a difference in maintaining precision at higher speeds.

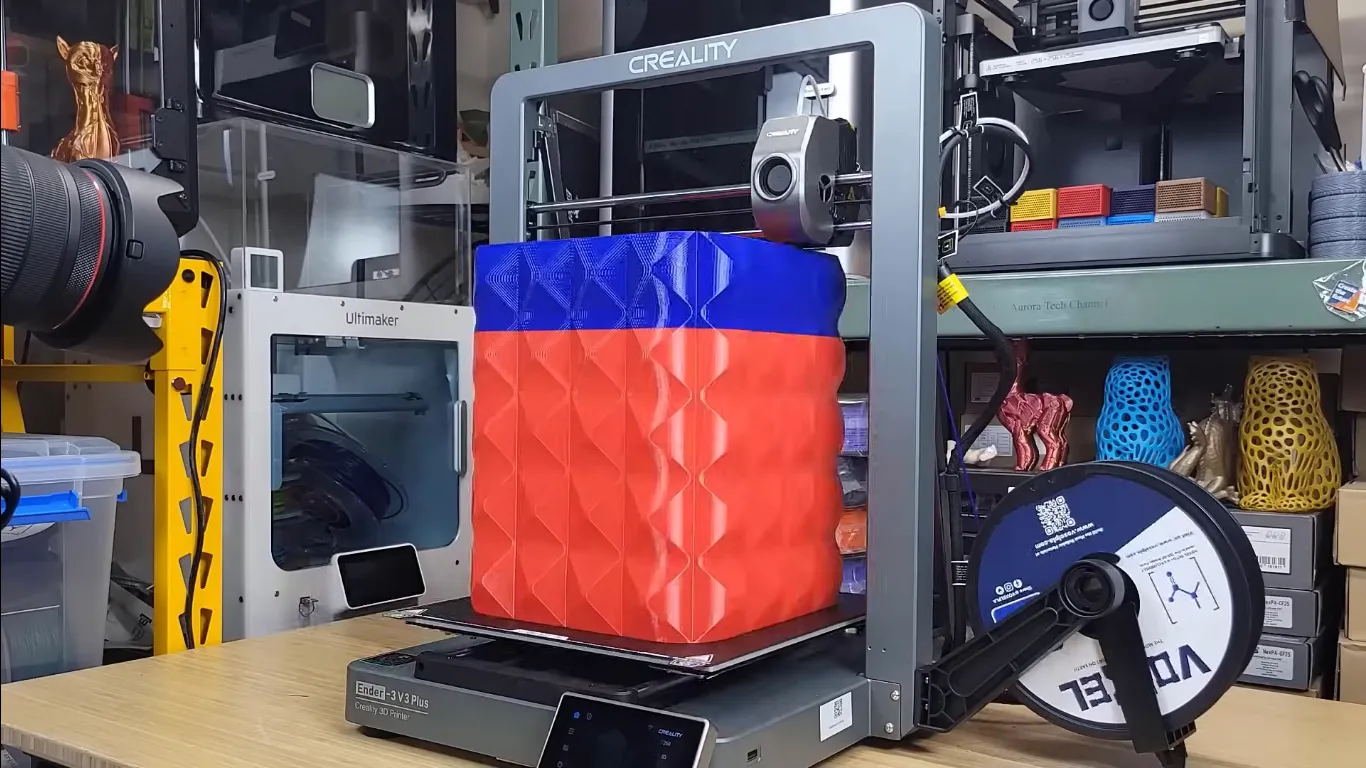

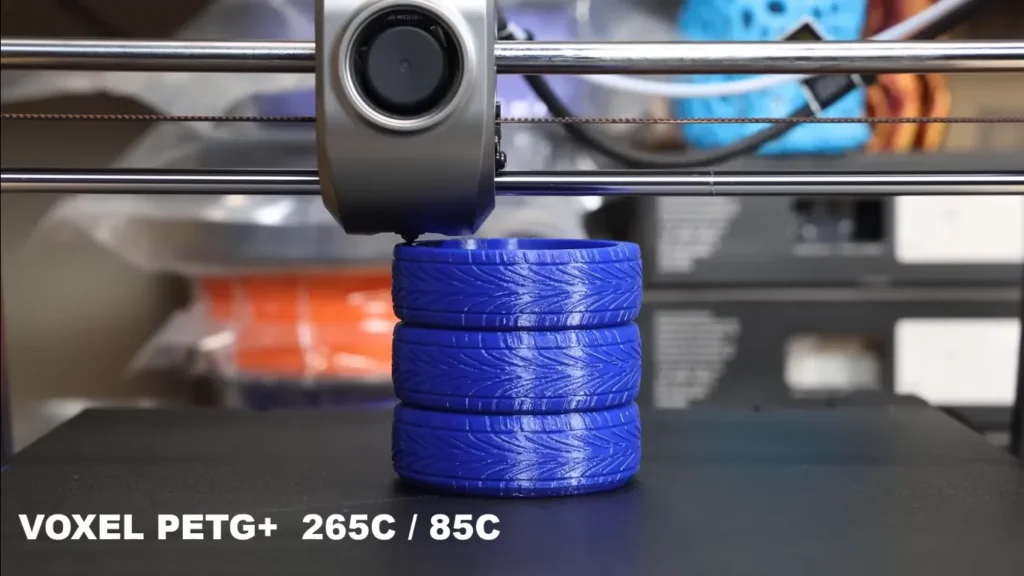

Material versatility is another strong point. While many budget printers struggle beyond PLA, the Ender 3 V3 Plus handled PLA, PETG, TPU, and even some engineering filaments with surprising ease. A multi-color architectural model that would have been challenging on previous generations printed beautifully, with clean transitions and minimal stringing.

Additional Features

4.3″ HD Color Touchscreen | Auto Bed Leveling | Filament Run-out Sensor | Power Loss Recovery | Open-source Creality OS | Creality Cloud App Integration | Dual Part Cooling Fans | Quick-swap Tri-metal Nozzle

Deeper Dive: CoreXZ Motion System Explained

The CoreXZ motion system isn’t just a technical buzzword – it’s a game-changer in printer design. Traditional 3D printers typically use either Cartesian or CoreXY mechanisms, but Creality’s approach is somewhat unique. By tightly coupling the X and Z axes, they’ve created a system that virtually eliminates the typical wobbling and vibration you’d expect from a budget printer.

During my testing, this became most apparent in taller prints. A 300mm architectural model that would have been a nightmare on previous Ender models came out remarkably clean. The dual Y-axis motors, each delivering 500mN.m of torque, ensure the print bed moves with precision that feels almost surgical. It’s like the difference between driving an old sedan and a sports car – the responsiveness is night and day.

Material Versatility: More Than Just PLA

While many budget printers are limited to basic PLA printing, the Ender 3 V3 Plus offers remarkable material flexibility. During my testing, I successfully printed with PLA, PETG, TPU, and even attempted some carbon fiber-infused filaments. The quick-swap “Unicorn” tri-metal nozzle, which combines steel tips, copper alloy, and a titanium alloy heatbreak, makes switching between materials surprisingly easy.

The hotend’s impressive 60-watt ceramic heater can reach 300 degrees Celsius in just 75 seconds, making it capable of handling higher-temperature materials like ABS with ease. This versatility transforms the Ender 3 V3 Plus from a hobbyist printer to a tool suitable for prototyping and small-scale production.

Filament Flexibility: Beyond the Basics

While the marketing emphasizes compatibility with various materials, the real-world performance is what truly impressed me. TPU, typically a nightmare for many budget printers, printed smoothly. Engineering filaments like PLA-CF (carbon fiber-reinforced) showed impressive dimensional stability.

The direct drive extruder with its bolster spring mechanism means even challenging flexible filaments become manageable. It’s not just about supporting multiple materials – it’s about providing consistent, high-quality prints across those materials.

Cooling System: The Unsung Hero

Those two part-cooling fans aren’t just about preventing stringing. The dynamic balancing and strategic placement mean more even cooling, better bridging performance, and reduced thermal deformation. During a complex multi-material print of a mechanical prototype, the cooling performance was particularly impressive – sharp overhangs, minimal post-processing required.

These additional insights should provide a more comprehensive understanding of what makes the Ender 3 V3 Plus more than just another budget 3D printer. It represents a thoughtful evolution of desktop manufacturing technology.

The Technical Magic: What Makes It Different

The printer’s Core XZ kinematics system isn’t just marketing speak. By rigidly connecting the X and Z axes, Creality has created a more stable printing platform. Two high-torque motors work in near-perfect synchronization, reducing vibrations and improving overall print consistency.

The newly designed direct-drive extruder is another standout feature. A bolster spring and ball plunger mechanism ensure consistent filament grip, virtually eliminating feed issues. During my testing, I ran through dozens of prints without a single clogging incident – a remarkable achievement for a printer in this price bracket.

Cooling has also received significant attention. Two strategically placed part-cooling fans rapidly cool freshly extruded material, dramatically reducing issues like drooping, warping, and stringing. The dynamic fan balancing is a subtle touch that makes a meaningful difference in print quality.

Thermal Management: More Than Just Heating

The 60W ceramic heater is a subtle but critical innovation. Heating from room temperature to 300°C in just 75 seconds isn’t just a spec sheet boast – it’s a practical advantage. For materials like PETG and ABS that require precise temperature control, this rapid and consistent heating makes a tangible difference.

The tri-metal “Unicorn” nozzle deserves special mention. The combination of a copper alloy base for rapid heat dissipation, a titanium alloy heat break to prevent heat creep, and a hardened steel tip for durability isn’t just marketing fluff. In practice, it means smoother filament flow, more consistent extrusion, and significantly longer nozzle life.

Creality Ender 3 V3 Plus Specifications Chart

| Feature | Specification |

|---|---|

| Printer Type | Fused Deposition Modeling (FDM) |

| Build Volume | 300 × 300 × 330 mm |

| Printer Dimensions | 410 × 445 × 577 mm |

| Weight | 11.5 kg |

| Printing Speed | Up to 600 mm/s |

| Acceleration | 20,000 mm/s² |

| Printing Accuracy | ± 0.2 mm |

| Layer Height | 0.1-0.35 mm |

| Filament Diameter | 1.75 mm |

| Nozzle | 0.4 mm (standard) |

| Nozzle Temperature | 300°C |

| Heatbed Temperature | 100°C |

| Supported File Formats | STL, OBJ, 3MF |

| Connectivity | WiFi, USB Drive, Creality Cloud |

| Price | Starts with $359.00 |

User Experience: Simplicity is Key

The 4.3-inch HD touchscreen is leagues ahead of previous Ender interfaces. Crisp graphics, intuitive navigation, and real-time print monitoring make the experience genuinely pleasant. Auto-calibration works remarkably well – no more wrestling with paper tests or manual bed adjustments.

Creality’s software ecosystem has also matured. The Creality Print slicer offers smart features like optimal cooling strategies and speed optimization. The Creality Cloud app allows remote print monitoring and management, transforming the Ender 3 V3 Plus into a genuinely connected device.

Software and Connectivity: The Ecosystem Advantage

Creality has clearly learned from previous iterations. The Creality Print software and Creality Cloud app represent a significant leap forward. It’s not just about slicing models anymore – it’s about creating an entire printing ecosystem.

The ability to manage multiple printers, monitor prints remotely, and access a library of 3D models transforms the Ender 3 V3 Plus from a standalone machine to a connected printing platform. This is a feature for the maker, the educator, or the small business, and goes far beyond the standard design and slicing workflow for 3D printing.

Print Farm and Professional Potential

While marketed as a hobbyist printer, the Ender 3 V3 Plus has serious potential for small-scale production. Wi-Fi connectivity and cloud printing features make it ideal for managing multiple printers simultaneously. I could easily see small makers or educational institutions deploying several of these machines.

The robust build quality – using aerospace-grade ADC12 aluminum alloy with impressive tensile strength – suggests this printer is built to handle continuous operation. Automatic belt tensioning and a Z-axis positioning accuracy of ≤15 micrometers further underscore its professional aspirations.

Thermal and Mechanical Innovations

The printer’s use of ADC12 aluminum alloy isn’t just a cost-cutting measure. With a tensile strength of ≥205 MPa and Brinell hardness of ≥75 HBW, this is a serious material choice. The integrated die-casting approach means fewer joints, less potential for misalignment, and ultimately more consistent print quality.

The automatic XZ belt tensioning is another feature that sounds minor but makes a massive difference in long-term printer performance. Belt slippage and tension issues have plagued 3D printers for years – Creality’s solution feels like a genuine innovation.

Real-World Considerations

No printer is perfect, and the Ender 3 V3 Plus has its limitations. The open-frame design means temperature-sensitive materials like ABS might require additional environmental control. While the printer claims ABS compatibility, consistent results will depend on your specific workspace.

The optional accessories like the Nebula Camera and Space PI Filament Dryer are nice but not essential. They enhance the experience but represent additional investment for those on a tight budget.

Pricing and Value Proposition

At around $479 (often on sale for $359), the Ender 3 V3 Plus represents exceptional value. Compared to competitors like the Elegoo Neptune 3 Plus or even Creality’s own higher-end models, it offers a compelling mix of features, speed, and reliability.

Should You Buy the Ender 3 V3 Plus?

Buy the Ender 3 V3 Plus if:

- You’re looking for an easy-to-use, reliable 3D printer that doesn’t require a PhD in engineering to operate

- You want impressive print speeds without sacrificing quality

- You’re a hobbyist, maker, or small business owner seeking a cost-effective printing solution

- You appreciate a user-friendly interface and smart connectivity features

Don’t buy the Ender 3 V3 Plus if:

- You require absolute top-tier, professional-grade printing performance

- You primarily work with temperature-sensitive materials like ABS in non-controlled environments

- You need an enclosed printer for consistent high-temperature printing

Final Thoughts

The Creality Ender 3 V3 Plus isn’t just another incremental update – it’s a meaningful leap forward in budget 3D printing. By focusing on user experience, reliability, and practical performance, Creality has created a printer that demystifies 3D printing for newcomers while offering enough sophistication to satisfy more experienced users.

If you’re looking to push the limits of your creativity or speed up the way your projects get done, and of course willing to invest a little more for the privilege, then the Ender 3 V3 Plus is definitely worth considering. It’s perfect for hobbyists wanting an easy, reliable entry into larger-format printing, makers seeking a versatile and quick printer, or small businesses and educational settings needing a dependable, user-friendly machine.

Is it perfect? No. But it’s remarkably close, especially considering the price point. After weeks of testing, I can confidently say that for anyone looking to explore 3D printing or upgrade from an older machine, the V3 Plus deserves serious consideration.

While Creality advertises up to 600 mm/s, practical optimal printing quality is achieved around 300 mm/s. Higher speeds can compromise print detail and surface finish.

The Ender 3 V3 Plus allows for a variety of materials to be used in printing — from at least 6 materials types, including PLA, PETG, ABS, TPU, PLA-CF & nylon carbon-fiber. Each material may require slight calibration for best results.

Most users can complete setup in 20-30 minutes. The printer comes largely pre-assembled, with clear instructions and color-coded components making the process straightforward, even for first-time 3D printer users.

No. While a computer can be helpful, the Ender 3 V3 Plus offers multiple ways to print: direct SD card upload, Wi-Fi connectivity through Creality Print, and the Creality Cloud mobile app for remote monitoring and file transfer.

Yes. Features like auto bed leveling, an intuitive touchscreen interface, and simplified software make it more accessible than previous Ender models. However, some basic technical understanding of 3D printing will help you get the best results.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.