Global automotive is collectively motoring towards greater sustainability, and 3D printing looks one heck of a jump start. The usage of additive manufacturing has allowed organizations to make components that are more environmentally-friendly, as well as those lighter and better suited for the job at hand, thus moving towards a greener world.

A prime example of this innovative approach is the BMW Group’s BMW M Visionary Materials Seat, which has recently been awarded the Altair Enlighten Award in the “Sustainable Processes” category at the Michigan Center for Automotive Research Seminar. This annual accolade recognizes groundbreaking lightweight and sustainable solutions in the automotive sector that minimize carbon, water, and energy consumption while promoting material recycling.

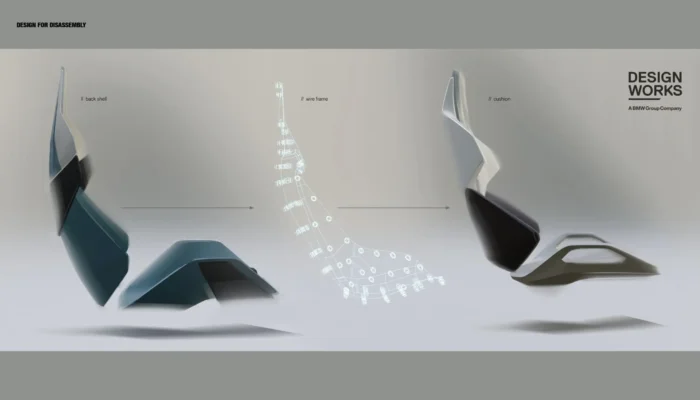

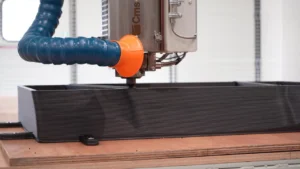

The production of this environmentally conscious seat was made possible through additive manufacturing, allowing BMW to forgo support structures and chemical post-processing. This achievement is the result of a collaborative effort involving the BMW design team for color and material concepts, along with partners such as Management Consulting GmbH, Bcomp Ltd, Gradel Light Weight Sàrl, and Lasso Ingenieurgesellschaft.

Falco Hollmann, Innovation Manager for Lightweight Design and Sustainability at BMW M GmbH, accepted the award, emphasizing the project’s forward-thinking approach: “We are showing today what will be possible tomorrow with existing technologies and materials in order to take our efforts to reduce emissions and conserve resources to the next level.”

The team focused on incorporating plant-based materials, enhancing recyclability, and creating an appealing design that balances high quality, lightweight construction, and functionality. This visionary seat serves as a launching pad for future process developments, particularly in sustainable seat design, with a holistic focus on the entire production life cycle.

Notably, the use of additive manufacturing and robot-wound support structures made from fiber composites and natural materials has led to a remarkable 90% reduction in CO2 footprint. Easy recycling is also made possible by the seat’s unmixed material usage and low module complexity.

Roberto Rossetti, Head of Development for the Complete Vehicle Life Cycle at the BMW Group, highlighted the importance of process chain optimization: “One of our biggest lessons was the balancing, in other words, how to model our process chain to generate missing primary data. The data obtained provides new insights, both in terms of today’s negative contributing factors and the design of tomorrow’s processes.”

This project is not only a proof of BWMs ambitions to be eco-friendly, but it also shows how 3D-printing can help in reshaping manufacturing processes for cars with minimal impact on the environment.

Source- press.bmwgroup.com

Read more recent news:

- NASA Forges ahead with Ceramic 3D printing for Space Mission

- Robotic Automation Revolutionizes Laser Marking Industry

- 3D Printed Homes Steal the Spotlight at America Makes Event

- Engineers explore cellulose nanofibrils to improve 3D-printed concrete

- Ireland’s First 3D Printed Homes Underway in Dundalk

Alexa Sipes is a U.S. tech journalist with 5 years of experience, now writing for 360TechInsights. She covers emerging technologies and industry trends across North America, Europe, and Asia. Sipes’ concise reporting offers readers valuable insights into the latest tech news, innovations and the companies behind them.

Feel free to reach out to me at AlexaSipes@360techinsights.com.