Ford accelerates Electric Explorer design using Formlabs 3D printers for rapid prototyping and tooling.

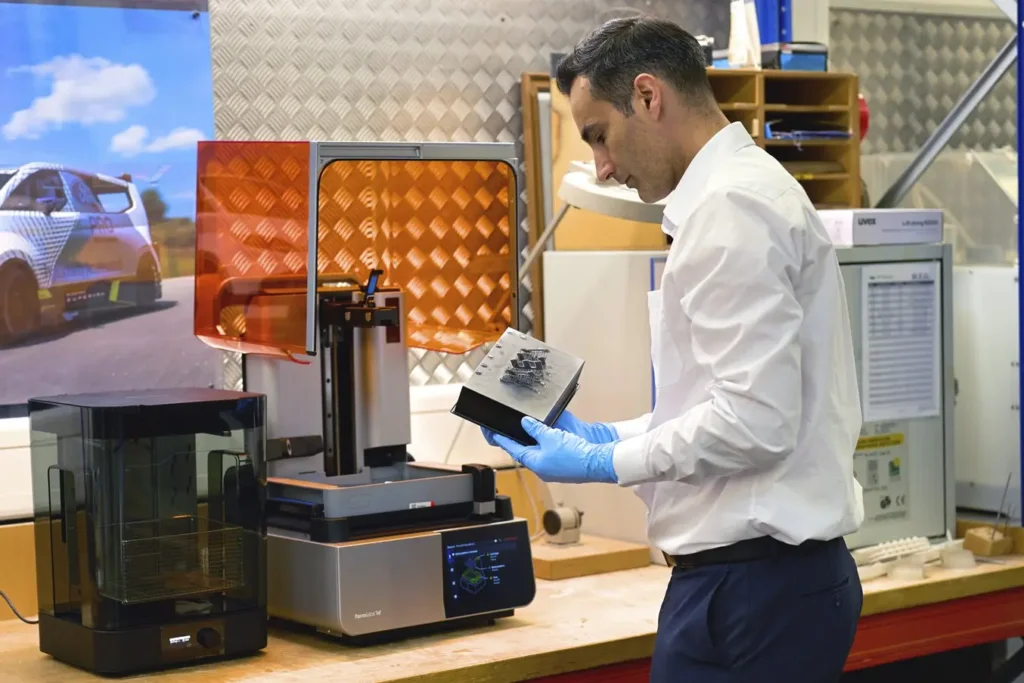

Ford Motor Company, a beta tester for the recently launched Formlabs Form 4, has revealed how 3D printing accelerated the design process of the new Electric Explorer. The automaker utilized a range of SLA and SLS 3D printers, including the Form 4, Fuse 1+, and Form 3L, alongside traditional manufacturing methods.

Ford’s designers leveraged these additive manufacturing tools to generate prototypes and tooling inserts, significantly speeding up the electrification process. The newest Formlabs printers allow for design requests to be completed within a day, even from distant locations that can ship overnight.

SLA technology made it possible to confirm the accuracy of both interior and exterior parts, such as the sideview mirror assembly. SLS proved crucial for mechanical testing, particularly for the complex charging port design.

Bruno Alves, Ford’s additive manufacturing expert and tooling specialist, emphasized the necessity of SLS for the charging cover: “It’s a really complex design that we are not able to produce in any other way. We cannot mill this part. We cannot use injection molding to produce just some samples.”

3D printing also complemented injection molding processes. For the Electric Explorer’s door handle, which requires two rubber components, designers 3D printed inset molds for their in-house injection molding machine. Alves noted, “Normally, external injection molding will take maybe two or three months. Internally, using additive manufacturing, we can speed up the process to maybe two weeks, three weeks maximum.”

This case study of Ford’s Electric Explorer design process underscores that speed is the most critical factor in 3D printing adoption, especially for prototyping. It also highlights the technology’s essential role in accelerating electrification in the automotive industry.

Source- formlabs

Read more recent news:

- Seeed Studio Unleashes Tiny Powerhouse Xiao RA4M1 Microcontroller

- Housing in 48 hours with worlds largest 3D printer from wood

- Rosatom Launches New Additive Technologies Centre at Belgorod State Agrarian University

- BMW’s 3D Printed Seat Wins Award in Automotive Sustainability

- NASA Forges ahead with Ceramic 3D printing for Space Mission

Alexa Sipes is a U.S. tech journalist with 5 years of experience, now writing for 360TechInsights. She covers emerging technologies and industry trends across North America, Europe, and Asia. Sipes’ concise reporting offers readers valuable insights into the latest tech news, innovations and the companies behind them.

Feel free to reach out to me at AlexaSipes@360techinsights.com.