Hi guys I’m Nikko Jenkins, a longtime fan of 3D printing. Today we’ll talk about the M3D Micro, and what it still delivers a decade later. So let’s get started! Famously, when the M3D Micro emerged in 2014 we were promised a product to turn the 3D printing world on its head with an inexpensive price tag and specific emphasis placed upon how little on your desk this would take up… Skip ahead to 2024 and we decided it was time for another glance at this little printer that captured the imagination of hobbyists far and wide. Does it still hold its ground in the ever-evolving 3D printing world today? Let’s dive in and find out.

What’s in the Box?

It is delivered as a fully assembled unit, which beginners will appreciate out of the box. In the box, you’ll find:

- The M3D Micro 3D printer

- M3D software for plug-and-play experience

- USB cable

- Power adapter (country-specific)

- Instructions

- Warranty (3 months for Standard Edition, 1 year for Retail Edition)

It’s the design of the Micro that will grab your attention first, with its adorable little cube form factor. Clocking in at a mere 7.3 inches (185 mm) per side, and weighing only a kilo – we can see why they called it “Micro”. On the back, you get a choice of black, white, blue or green for colored versions and orange or clear for see-through cases.

Pros ✅

+ Extremely compact design

+ Simple, plug-and-play operation (when it works)

+ Capable of good print quality at its best

+ Compatible with a wide range of materials

+ Removable, flexible build plate

Cons 📛

– Small build volume

– Slow print speeds

– Reliability issues reported by many users

– Limited customer support and replacement parts

– Proprietary software with limitations

– Price no longer competitive with current market offerings

Specifications

Let’s break down the key specs:

- Print technology: FDM (Fused Deposition Modeling)

- Build volume: 109 x 113 x 116 mm (but it gets a bit smaller as you go up)

- Layer resolution: 50-350 microns

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Connectivity: USB

- Compatible materials: ABS, PLA, nylon, and M3D’s proprietary “professional” and “chameleon” filaments

- Software: Proprietary M3D software

At first glance, these specs might not blow you away in 2024. But remember, this little guy was a trailblazer in its day, offering features like auto bed leveling and a removable print bed when those were still considered premium add-ons.

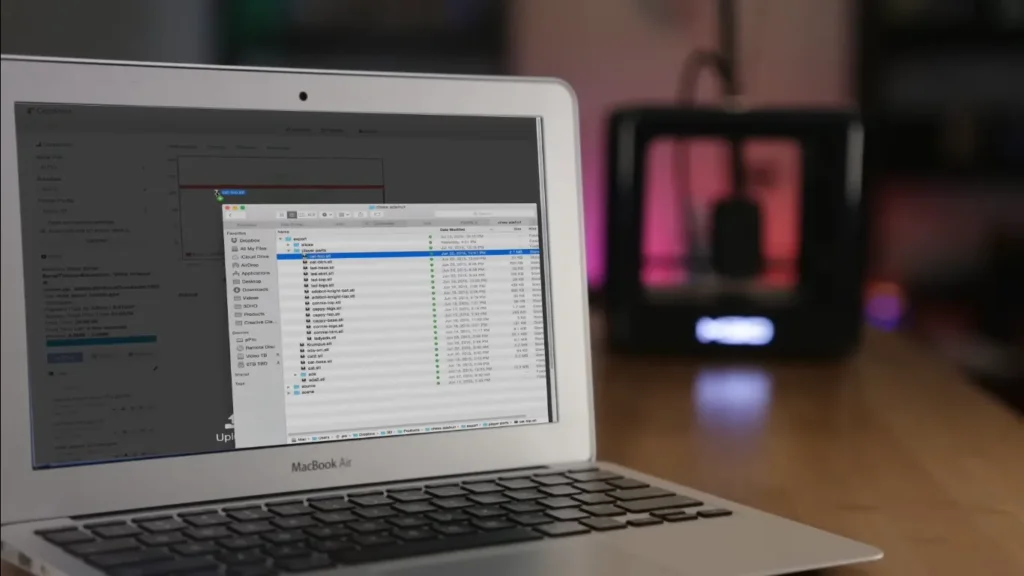

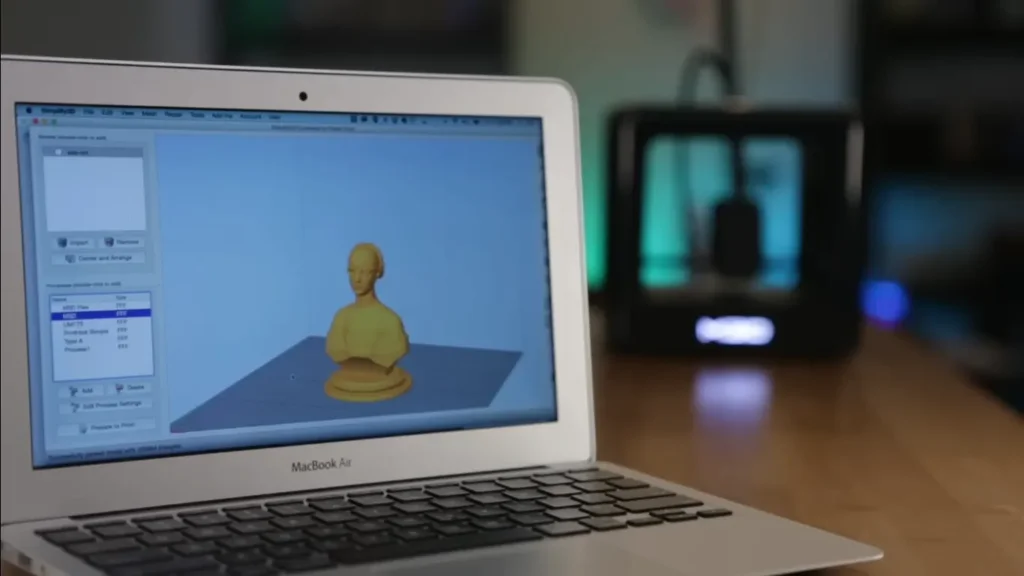

Setup and Software

Easy-to-use has always been one of the Micro’s selling points. The M3D software has been specifically created for a simple plug-and-play experience, and it endorses. stl and. obj file types. One nice touch: It’s Mac and PC compatible.

However, user experiences seem to vary widely. Although some described the setup process as incredibly straightforward and had positive results out-of-the-box, it seems others encountered problems with calibration and wonky software. This should be contrasted with today, when there are more user-friendly options available now than will ever have been on the market by 2024.

Print Quality

The M3D Micro boasts a layer resolution of 50-350 microns, which is actually quite impressive for its size and price point. When everything aligns perfectly, this little printer can produce some surprisingly detailed models.

However, consistency seems to be an issue. Many users report that while they can achieve good quality prints, it often takes a fair bit of tinkering and failed attempts to get there. ABS is also trickier to print, largely due to the lack of a heated bed and some added carefulness during printing.

Speed

In the 3D printing world, speed is not everything but it is still important. The M3D Micro is, to put it kindly, not the speediest printer on the block. Its 15W power consumption and 5V stepper motors mean that print times can be considerably longer than what you’d expect from more modern printers.

This might not be a deal-breaker if you’re printing small objects and don’t mind waiting. But for larger projects or if you’re looking to iterate quickly, the Micro’s leisurely pace could test your patience.

Filament Handling

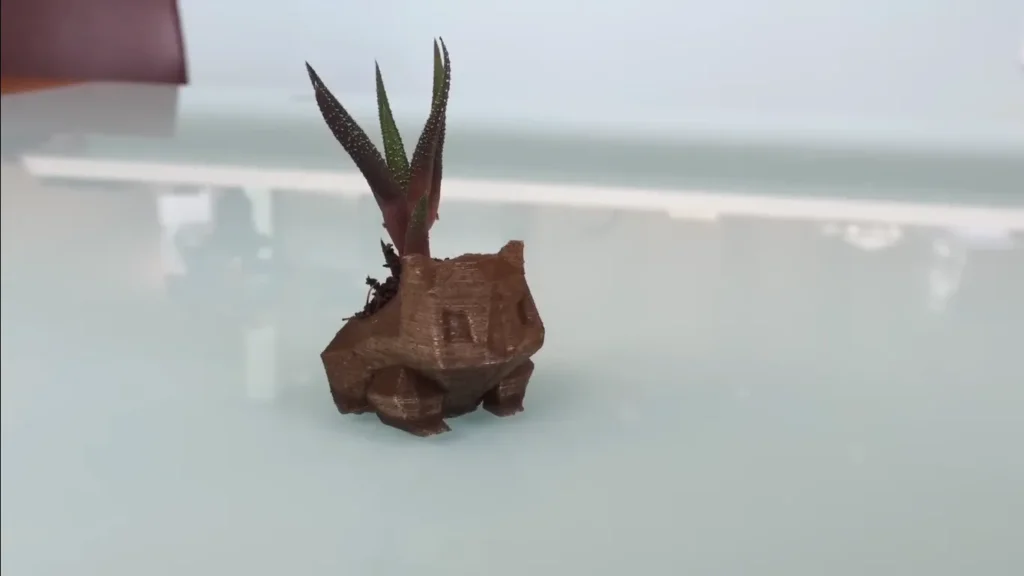

The M3D Micro has a clever design feature where the print bed pops up to reveal a filament compartment. This allows you to use M3D’s proprietary half-pound filament spools, which is neat for keeping things tidy.

However, there’s a catch. Many users report that using filament from this internal compartment can cause issues, as the printer sometimes struggles to pull the filament, leading to failed prints. The workaround? Using an external filament spool – but the printer doesn’t come with an external spool holder. You’ll need to either buy one or, ironically, 3D print one using models available on M3D’s website.

But the M3D Micro uses typical 1.75 mm filament and doesn’t seem to lock you into their materials on pricing-at least not yet. Which leads us to an entire realm of filament possibilities, such as filaments made from exotic materials like woodfilled or metalfilled PLA.

Reliability

Here’s where things get a bit tricky. While some users report having great experiences with their M3D Micro, lasting for years without major issues, others tell a different story. Common complaints include:

- Calibration issues: The auto-leveling feature doesn’t always work as advertised, leading to prints that fail to adhere to the bed or have inconsistent first layers.

- “Head burying”: Several users report a bizarre issue where the print head tries to bury itself into the print bed, potentially damaging both.

- Belt problems: The belts seem to be a weak point, with many users reporting the need for frequent replacements.

- Limited support: As the printer has aged, getting replacement parts or technical support has become more challenging.

- Software quirks: The proprietary software, while user-friendly in theory, can be buggy and lacks some features found in more robust slicing programs.

These issues highlight a key point: while the M3D Micro might be a fun intro to 3D printing, it may not be the most reliable option for serious or consistent use.

Price Point

It was a ground-breaking price when the M3D Micro launched sub-$400. However in 2024 things look quite different. Today, there are several more modern and generally less expensive printers with better features to choose from that make it a tougher sell at its current price of $449.

This includes larger print beds, higher printing speeds and a more active community for help of upgrades at an even lower cost with printers like the Ender 3 series. Unfortunately, that puts the M3D Micro in a difficult position for almost everyone but salarymist followers of tiny stereolithographic printing process.

Who Is It For?

Given its limitations and the current market, the M3D Micro in 2024 might appeal to:

- Nostalgia seekers: If you’ve been curious about this printer since its Kickstarter days, it might be fun to finally get your hands on one.

- Space-constrained makers: Its tiny footprint makes it suitable for small desks or cramped workspaces.

- Beginners who prioritize simplicity: If you want the most straightforward entry into 3D printing and don’t mind the small build volume, it could be a starting point.

- Schools or libraries: Its compact size and relatively simple operation could make it suitable for educational settings where space is at a premium.

The Verdict

At the time it was first released, the M3D Micro presented a “revolution in 3D printing”. With its small form factor, low cost and very approachable method to 3D printing brought lots of people in the wake. In 2024, however, it’s hard to recommend as a primary printer for most users.

The world of 3D printing has changed a lot in the years since the M3D Micro was first announced. Nowadays even budget printers give you way more print area faster prints and possibly less problems for a lower price than back then. While the Micro retains its charm as a compact, beginner-friendly option, it’s hard to justify its current price point given the alternatives available.

Some may still be attracted to the M3D Micro due to its small size, or because they want a piece of 3D printing history. The sad truth is that most of the folks who would buy this as their first 3D printer in 2024 are going to have a better local option available at nearly equivalent prices.

Final Thoughts: A Pioneer Past Its Prime

The M3D Micro is an interesting example of how quickly consumer 3D printing has advanced. Ten years on, the same recipe is beginning to look slightly rusted in a rapidly evolving domain that has moved higher and further.

While it’s probably not worth recommending the 2014 M3D Micro to most users in 2024, we can at least respect its place for helping bring widespread adoption of desktop 3D printing. It laid the groundwork for all of those amazing low cost printers we now have. For that, the little cube-shaped printer deserves a nod of respect, even as we look to newer, more capable machines for our printing needs.

If you do decide to take a chance on the M3D Micro, approach it with the mindset of exploring a piece of 3D printing history. Just be prepared for a bit of tinkering, some potential frustration, and print times that might have you reaching for a good book while you wait. Who knows? You might find charm in its quirks and limitations, much like enthusiasts who still love to tinker with vintage cars or retro gaming consoles.

In the end, the M3D Micro reminds us of how far we’ve come in the world of consumer 3D printing – and gets us excited about where we might go next. Here’s to the pioneers, even when they’ve been outpaced by the very revolution they helped start.

:FAQs:

What Happened to M3D Printers?

M3D’s journey took an unexpected turn in 2018 when they pulled the M3D Pro from their store. By early 2022, their website only offered documentation and drivers, with no option to purchase new printers. This development raises concerns about product availability, support, and long-term viability for M3D printers like the Micro. Potential buyers in 2024 should be aware that finding new units, getting support, or sourcing replacement parts may be challenging. This situation serves as a reminder of the risks associated with tech products from smaller companies in rapidly evolving markets

Does the M3D Micro 3D printer require assembly?

No, the M3D Micro is designed for easy setup right out of the box. Just attach the print bed and load the filament to get started.

What types of filament are compatible with the printer?

The M3D Micro works with standard ABS and PLA filaments. More exotic materials like flexibles and composites generally don’t print well.

Can I connect the printer via WiFi or is it USB only?

Connectivity is limited to USB only. The M3D Micro does not offer wireless printing capabilities.

Is there an enclosure available for the open frame body?

Yes, third party acrylic enclosures are available from online retailers to enclose the Micro for better temperature regulation.

Do I need technical expertise to use the M3D printer software?

No, the integrated M3D software aims to provide intuitive controls optimized for beginners without much technical know-how.

What is the smallest 3D printer?

The M3D Micro is one of the most compact desktop 3D printers at just 7.3″ cubed. The Peachy Printer Mini is also extremely small at 5″ cubed.

What is the world’s best 3D printer?

The Prusa i3 MK3S+ is considered one of the best desktop 3D printers for its reliability, print quality, large community support, and consistent updates.

What’s the cheapest 3D printing technology?

Fused filament fabrication (FFF) using common thermoplastics like ABS and PLA is the most affordable 3D printing technology for home use. Resin printing offers higher detail but at a higher cost.

What is fastest 3D printer?

Industrial grade production 3D printers such as the Stratasys Fortus 450mc boast incredibly fast print speeds over 900mm/s. More affordable consumer models max out around 200-300 mm/s.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.

Pingback: OMTECH PRO 2440 Review: Best Budget CO2 Laser Engraver in 2024

Pingback: xTool S1 Review: King of the New Era with Surprising Features and Performance!

Pingback: Bambu Lab X1 Carbon Review: A Game-Changer in the World of 3D Printing

Pingback: CREATBOT F160 Review - Is this the Best 3D Printer in 2024?