New 3D printing method creates tough, stretchy Sticky Hydrogels, transforming medical implants and tissue engineering.

A revolutionary 3D printing process, recently featured in Science, is poised to redefine hydrogel-based medical adhesives. Developed by researchers at the University of Colorado Boulder, in collaboration with the University of Pennsylvania and NIST, this innovative technique tackles longstanding challenges in creating biomaterials that are both durable and adaptable for medical applications.

3D printing technology has long tantalized researchers with its potential to create complex shapes and structures for medical use. However, the field has been hampered by limitations in material properties. Ideal biomaterials for medical applications need to be strong, stretchable, and capable of adhering to dynamic living tissues like the beating heart or the tough cartilage in joints. Traditional 3D printed hydrogels, despite significant advances, often fall short – breaking when stretched or cracking under pressure, while others prove too rigid to conform to deformable tissues.

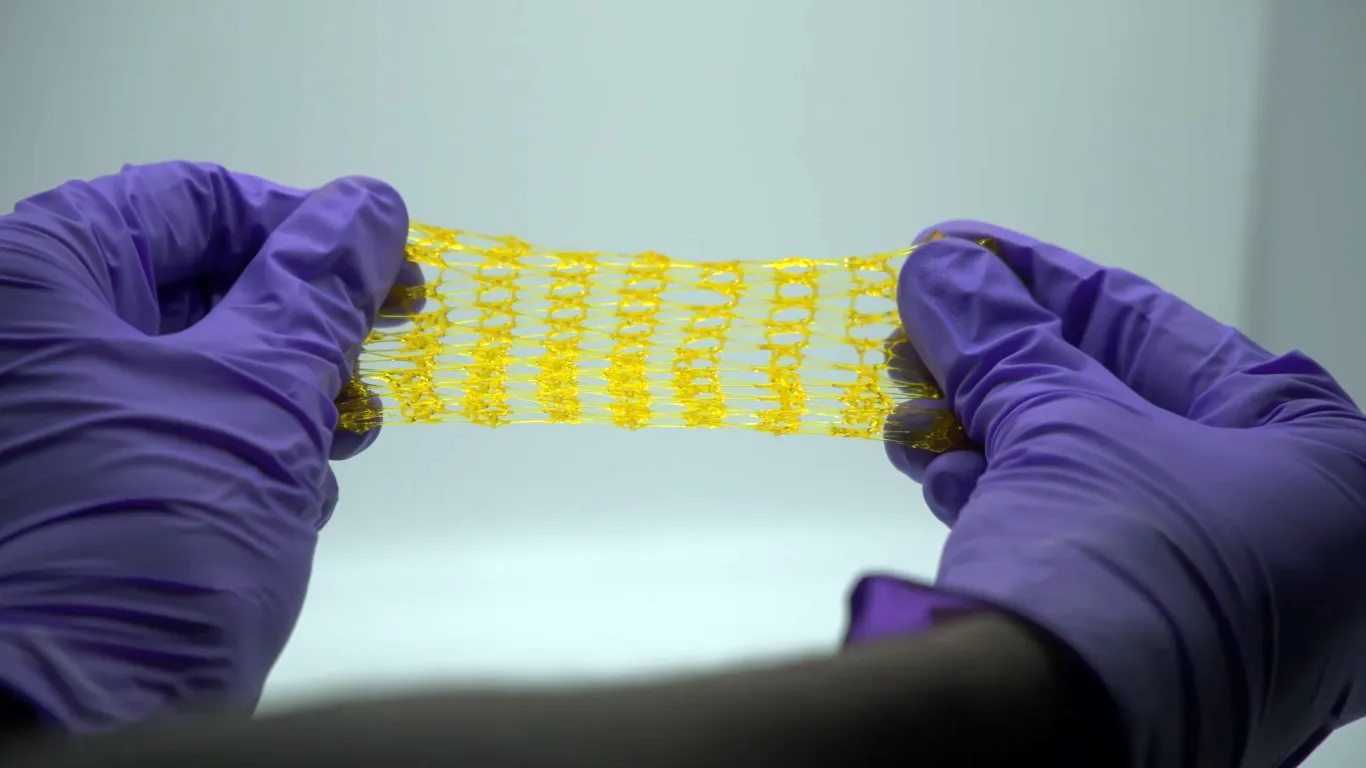

Enter CLEAR: Concurrent Light-triggered and Entanglement-driven Additive Restructuring. This novel method ingeniously combines two polymerization processes to enhance the properties of 3D printed hydrogels. By simultaneously employing spatial light illumination (photopolymerization) to set an object’s shape and a complementary redox reaction (dark polymerization) to gradually produce a high concentration of entangled polymer chains, CLEAR creates hydrogels with unprecedented strength and elasticity.

“This was developed by a graduate student in my group, Abhishek Dhand, and research associate Matt Davidson, who were looking at the literature on entangled polymer networks,” explains Jason Burdick from CU-Boulder’s BioFrontiers Institute. “In most of these cases, the entangled networks that form hydrogels with high levels of certain material properties…are made with very slow reactions. This is not compatible with [digital light processing], where each layer is reacted through short periods of light. The combination of the traditional [digital light processing] with light and the slow redox dark polymerization overcomes this.”

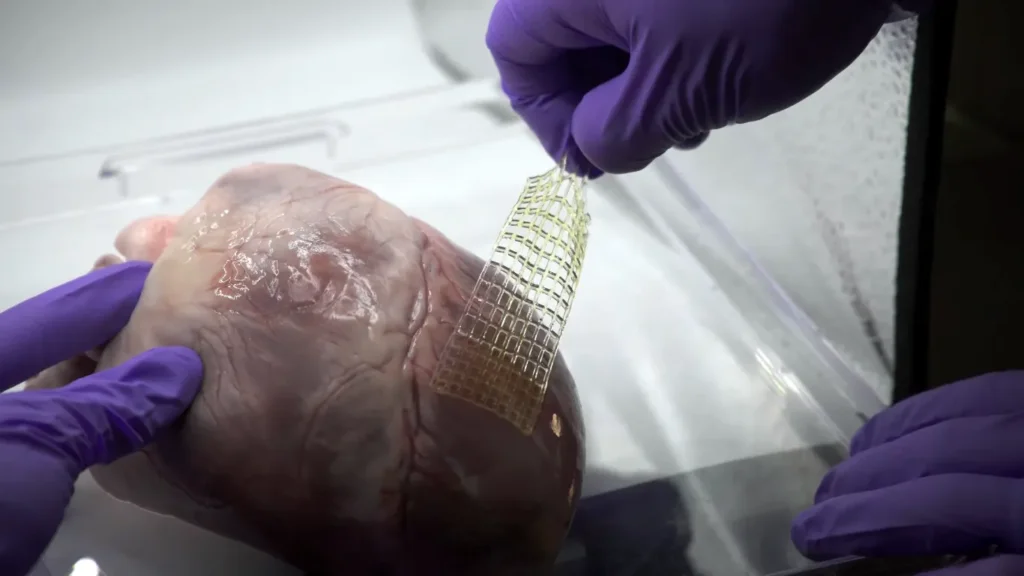

The results are striking. Experiments confirmed that CLEAR-produced hydrogels were four to seven times tougher than those created using conventional digital light processing methods. Moreover, these hydrogels demonstrated an impressive ability to conform and adhere to animal tissues and organs.

Burdick elaborates on the potential applications: “We illustrated in the paper the application of hydrogels printed with CLEAR as tissue adhesives, as others had previously defined material toughness as an important material property in adhesives. Through CLEAR, we can then process these adhesives into any structures, such as porous lattices or introduce spatial adhesion that may be of interest for biomedical applications.”

The implications of CLEAR extend beyond biomedicine. The technique could have environmentally friendly applications in manufacturing by eliminating the need for additional light or heat energy to harden parts. Furthermore, Burdick notes that CLEAR’s versatility may allow it to be used with other materials like elastomers and across various manufacturing methods.

While the current work primarily serves as proof-of-concept, demonstrating the method’s potential across a range of applications, the next steps are clear. “The next step is to identify those applications where CLEAR can make an impact and then further explore those topics, whether this is specific to biomedicine or more broadly beyond this,” Burdick states.

As research continues, with additional studies planned to better understand tissue reactions to the printed hydrogels, the medical community eagerly anticipates the potential of CLEAR to revolutionize tissue engineering, implant design, and beyond. The researchers have filed for a provisional patent, marking the first step towards bringing this groundbreaking technology from the laboratory to real-world medical applications.

Content source – colorado.edu

Read more recent news:

- Creality Launches K1 SE: Affordable High-Speed Printing

- Ford Accelerates Electric Explorer Design with Advanced 3D Printing

- Seeed Studio Unleashes Tiny Powerhouse Xiao RA4M1 Microcontroller

- Housing in 48 hours with worlds largest 3D printer from wood

- Rosatom Launches New Additive Technologies Centre at Belgorod State Agrarian University

Nestor Sawayn is a U.S.-based tech journalist specializing in maker tools and creative technologies. His coverage spans 3D printers, vinyl cutters, paper printers, and laser cutters across North America, Europe, and Asia. Sawen’s articles offer concise, insightful analysis of the latest News, innovations in this space. Beyond hardware, he explores the creative potential of board games and tabletop RPGs, providing readers with a comprehensive view of both digital and analog maker trends.

Feel free to reach out to me at nestorsawayn@360techinsights.com.