After spending several weeks with both the Creality K2 Plus and the Bambu Lab X1 Carbon, putting them through their paces with everything from quick Benchy prints to marathon multi-color projects, I’ve got some thoughts to share. When it comes to consumer 3D printing, these two machines represent the pinnacle of the category, and picking between them is not a simple matter.

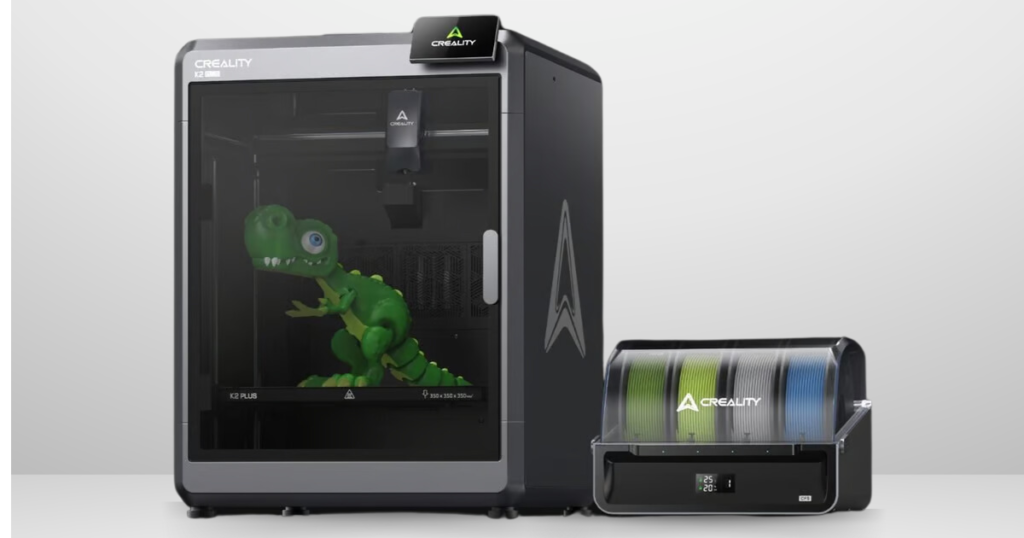

Creality K2 Plus

Released: 2024 July

Key Features: 350 × 350 × 350 mm³ | Die-cast aluminum “Matrix” frame | Actively heated chamber (60 °C) | CFS (16-color system) | 30,000 mm/s² acceleration | Dual AI cameras | High-flow hotend (350 °C) | Strain gauge leveling | Air purifier | USB, Wi-Fi & Ethernet

Price Range: $1,499

Bambu Lab X1 Carbon

Released: 2022 Nov

Key Features: 256 × 256 × 256 mm³ | Dual auto bed leveling | 7μm lidar resolution | Spaghetti detection | AI inspected first layer | Carbon fiber gantry

Price Range:Starts with $1,199

The First Impression

Right out of the box, these printers make distinctly different impressions. The K2 Plus is a monster coming in at nearly 99 lbs with a huge 350mm cubic print volume. Almost as if a mini-fridge was dropped off right on your porch. The X1 Carbon, while still substantial, feels more manageable with its 256mm cubic build volume and roughly 31-pound weight (with the AMS installed).

The size difference isn’t just about the numbers – it’s about the space these machines demand in your workspace. The K2 Plus required a literal reshaping of my desk area, whereas the X1 Carbon snuggled right into my existing desk setup. That said, the extra build volume of the K2 Plus has come in handy more times than I expected, especially when batch printing items for my test projects.

Winner: Tie – The X1 Carbon wins for compatibility with smaller spaces, but the K2 Plus takes it for those needing maximum build volume.

Creality K2 Plus vs Bambu Lab X1 Carbon Specification Chart

| Specification | Creality K2 Plus | Bambu Lab X1 Carbon |

|---|---|---|

| Price | $1,499 MSRP | $1,199 (Base), $1,449 (Combo) |

| Build Volume | 350 × 350 × 350 mm³ | 256 × 256 × 256 mm³ |

| Maximum Speed | 600 mm/s | 500 mm/s |

| Maximum Acceleration | 30,000 mm/s² | 20,000 mm/s² |

| Multi-Color Capability | Up to 16 colors (4 colors per CFS, expandable) | Up to 16 colors with AMS |

| Hot End Temperature | Up to 350°C | Up to 300°C |

| Bed Temperature | Up to 180°C | 110°C (220V), 120°C (110V) |

| Supported Materials | PLA, ABS, PGP, PU, PA, ASA, and others | PLA, PETG, TPU, ABS, ASA, PVA, PET, PA, PC, Carbon/Glass Fiber |

| Enclosure | Fully enclosed with anti-shatter glass door | Fully enclosed |

Setup and First Prints

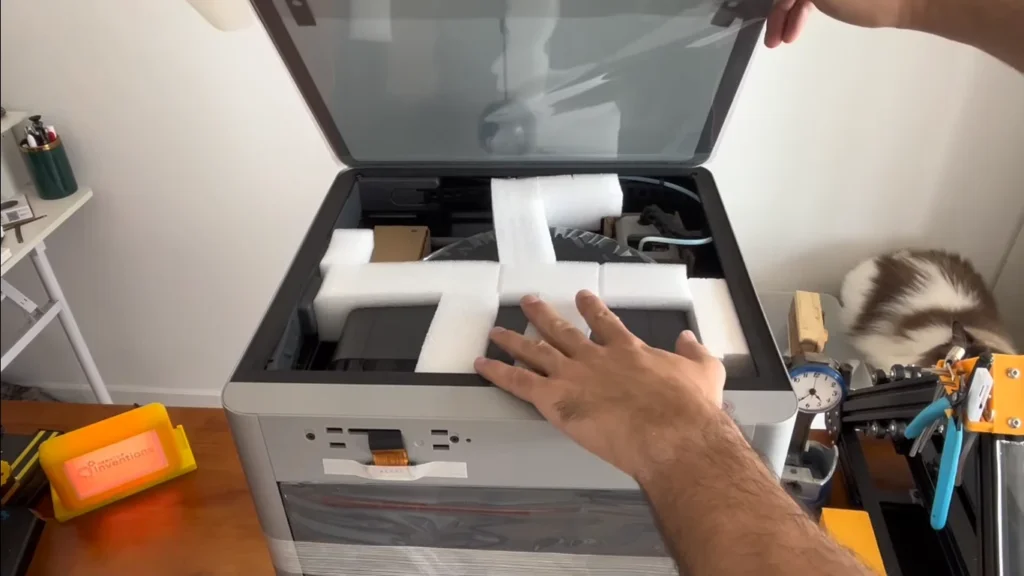

Setting up the X1 Carbon feels like unboxing a premium consumer electronics product. Everything is thoughtfully packaged, and the setup process is remarkably straightforward. Within about 15 minutes, I had the printer assembled and ready for its first print. The AMS (Automatic Material System) slots in easily, and the whole system just feels refined.

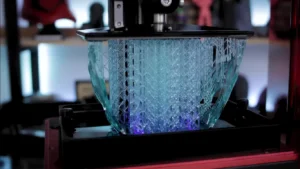

The K2 Plus setup takes a bit more effort, primarily due to its size and weight. The CFS (Color Filament System) comes pre-installed inside the machine, which is convenient for shipping but means you’ll need to do some rearranging to get everything in place. The process isn’t difficult, but it does require more time and attention than the X1 Carbon.

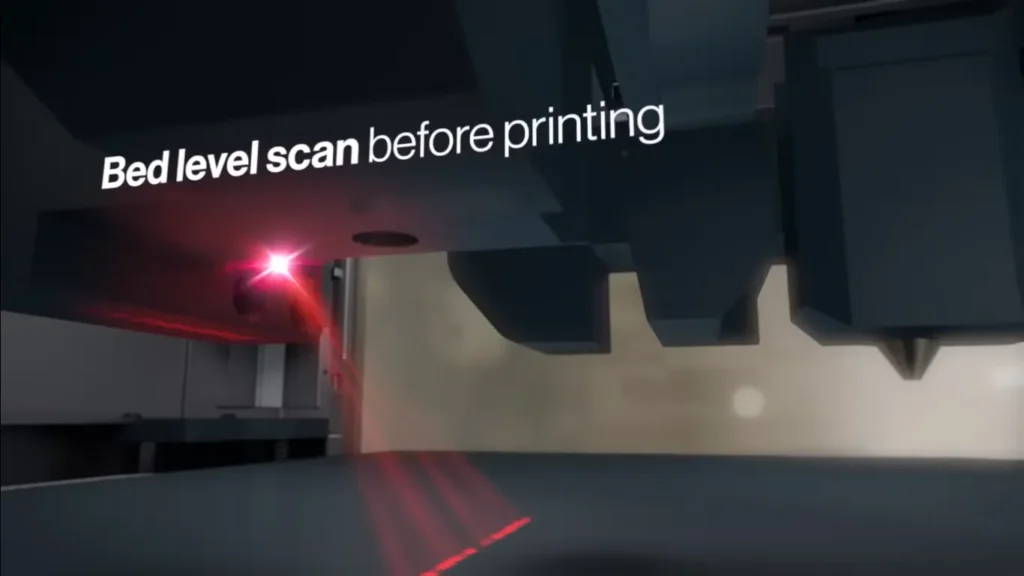

Both printers feature auto-bed leveling, but I found the X1 Carbon’s dual auto-bed leveling system, which uses both lidar and analog force sensors, to be more reliable out of the box. The K2 Plus’s system works well, but occasionally needed minor adjustments to get perfect first layers.

Winner: Bambu Lab X1 Carbon – Its refined setup process and superior auto-bed leveling give it the edge.

Print Quality and Speed

Here’s where things get really interesting. Both machines are marketed as high-speed printers, with the K2 Plus boasting speeds up to 600mm/s and the X1 Carbon claiming 500mm/s. In my testing, both printers lived up to their speed claims, but with some important caveats.

I printed multiple Benchys on both machines at various speeds. The X1 Carbon consistently produced cleaner results at high speeds, likely due to its lighter toolhead and more refined input shaping. A 15-minute Benchy on the X1 Carbon looked nearly as good as a standard-speed print, while the K2 Plus needed some tuning to achieve similar quality at its highest speeds.

However, the K2 Plus showed impressive strength in larger prints. Its rigid frame and beefier construction really shine when printing tall objects. I printed several helmet pieces on both machines, and the K2 Plus handled them with noticeably less vibration, especially in the upper layers.

Both printers use direct drive extruders, but the X1 Carbon’s toolhead feels more refined and precise. The K2 Plus’s “Apus” direct drive system is no slouch, but it occasionally struggled with rapid retractions in detailed areas.

Winner: Bambu Lab X1 Carbon – While both printers are incredibly capable, the X1 Carbon’s more refined motion system gives it a slight edge in print quality, especially at high speeds.

Multi-Color Printing

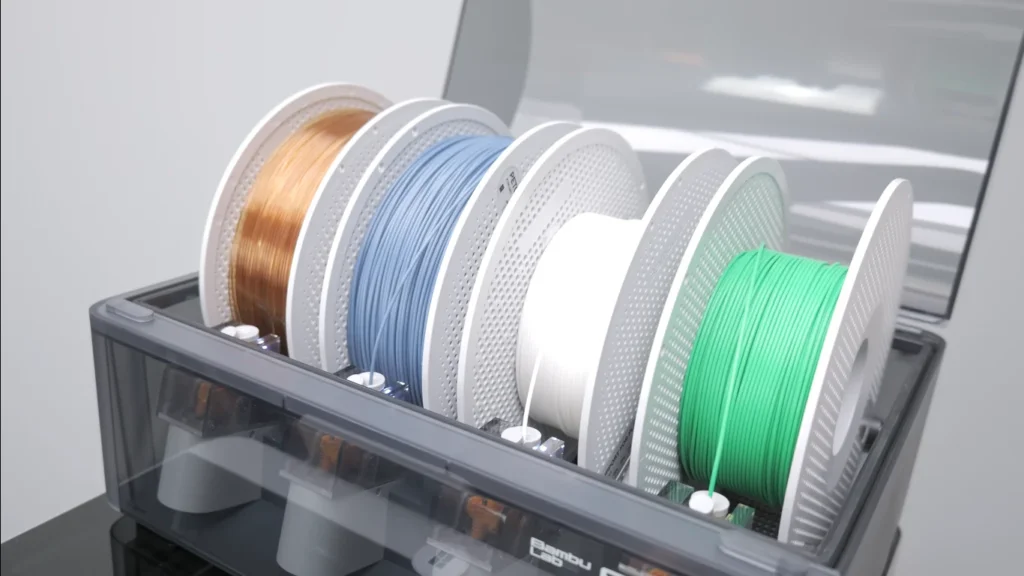

This is where both printers really show their innovation. The X1 Carbon’s AMS supports up to four colors, while the K2 Plus’s CFS can theoretically handle up to 16 colors when expanded with additional units. In practice, I spent most of my time testing with four colors on each machine.

The X1 Carbon’s color changes are more refined and waste less filament during transitions. The purge process is efficient, and the resulting multi-color prints are consistently clean. I printed several multi-color toys and decorative pieces, and the color transitions were nearly perfect every time.

The K2 Plus’s CFS system, while newer to the market, shows promise. It handles color transitions reliably, though it tends to use more filament in the purge process. One advantage of the K2 Plus is its filament management system, which includes humidity monitoring and better storage conditions for the loaded filaments.

What really impressed me was the K2 Plus’s ability to maintain consistent quality across long multi-color prints. I ran several 20+ hour prints with multiple color changes, and the results were remarkably consistent. The X1 Carbon performed admirably as well, but occasionally needed adjustment for longer prints.

Winner: Tie – The X1 Carbon offers more refined color transitions, while the K2 Plus provides better filament management and expandability.

Software and Connectivity

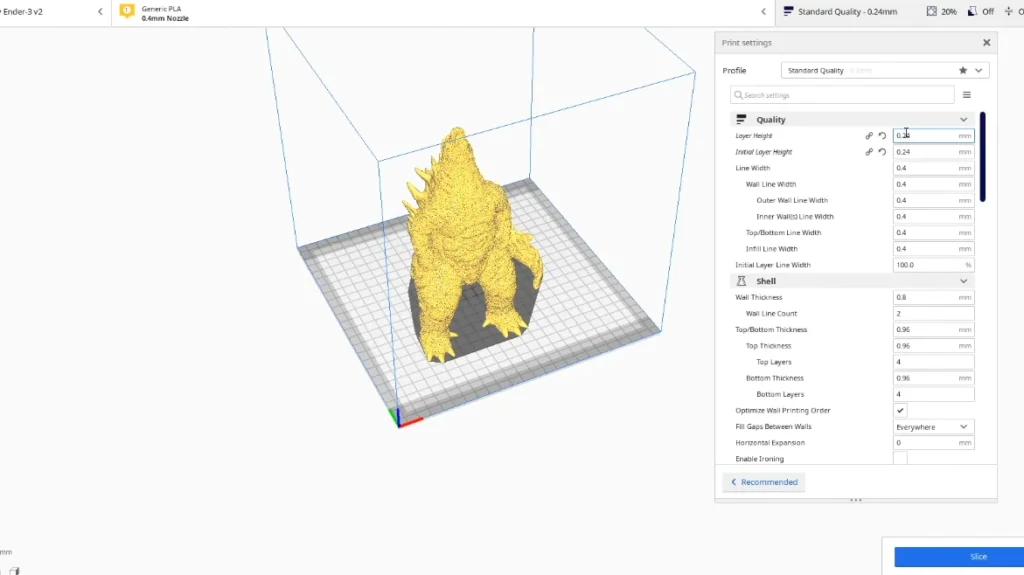

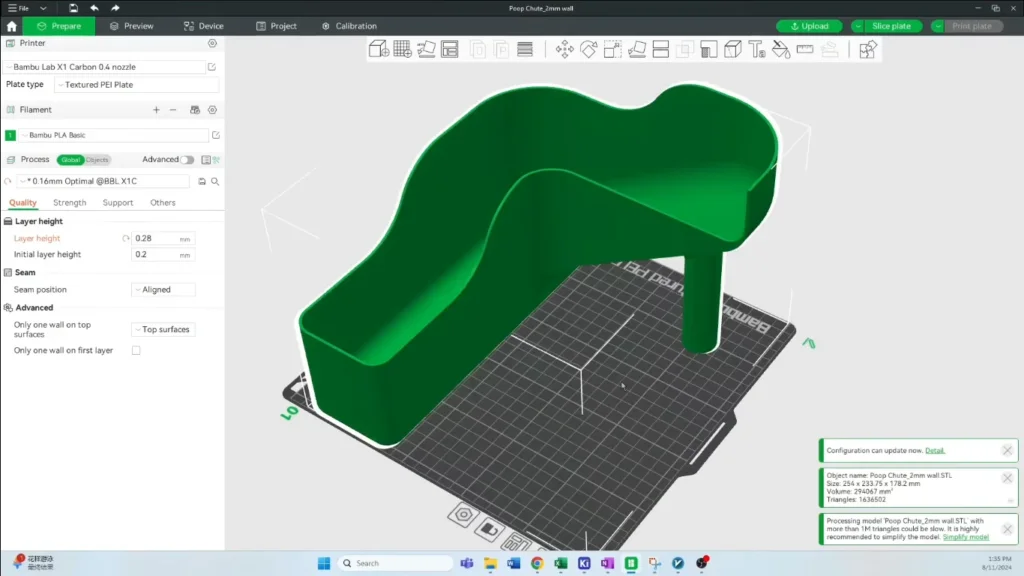

The software experience differs significantly between these machines. The X1 Carbon uses Bambu Studio, a modified version of PrusaSlicer that provides a polished, user-friendly experience. The software is intuitive, and the integration with the printer’s features is seamless. I particularly appreciated the mobile app integration, which made monitoring prints and receiving notifications a breeze.

The K2 Plus relies on Creality Print, which has come a long way but still feels less refined than Bambu Studio. However, it handles multi-color printing well and includes all the necessary features for getting the most out of the printer. The printer’s connectivity options are solid, including WiFi and USB support, though the USB port placement could be more convenient.

Both printers feature built-in cameras for monitoring prints, but the X1 Carbon’s AI-powered failure detection gives it an edge in reliability. I’ve had several prints saved by its ability to detect potential failures before they become disasters.

Winner: Bambu Lab X1 Carbon – Its more polished software experience and advanced monitoring features make it the clear winner in this category.

Material Compatibility and Environmental Control

Both printers feature heated chambers and can handle a wide range of materials, but they approach thermal management differently. The K2 Plus’s larger chamber can reach higher temperatures, making it more suitable for materials like ABS and ASA. Its bed can reach 180°C, compared to the X1 Carbon’s 110°C (at 220V).

I tested both machines with various materials, from basic PLA to more exotic filaments like carbon fiber-filled nylon. The X1 Carbon handled everything competently, but the K2 Plus’s higher temperature capabilities and more powerful heating system gave it an advantage with high-temperature materials.

The K2 Plus also features better active cooling, with fans on both sides of the build plate. This resulted in better bridging and overhang performance, especially on larger prints. The X1 Carbon’s cooling is adequate for most purposes, but it can struggle with particularly challenging geometries.

Winner: Creality K2 Plus – Its superior thermal management and higher temperature capabilities give it the edge for advanced materials.

Build Quality and Reliability

After several weeks of heavy use, both printers have shown their strengths and weaknesses in terms of reliability. The X1 Carbon feels more refined overall, with better quality control and more polished components. Its carbon fiber gantry and lightweight design contribute to consistent print quality.

The K2 Plus’s industrial-grade construction inspires confidence, particularly with its four Z rods and dual Z steppers. The enclosed chamber feels solid, and the anti-shatter glass door is a thoughtful safety feature. However, I experienced occasional minor issues with filament feeding that required adjustment.

Both printers use high-quality components where it matters most. The X1 Carbon’s all-metal hotend and the K2 Plus’s “Unicorn” nozzle both performed excellently throughout testing. The K2 Plus’s FOC closed-loop motors are notably quiet, while the X1 Carbon’s motion system is slightly more precise.

Winner: Bambu Lab X1 Carbon – While both are well-built, the X1 Carbon’s more refined engineering and better quality control give it a slight advantage.

Advanced Features and Innovation

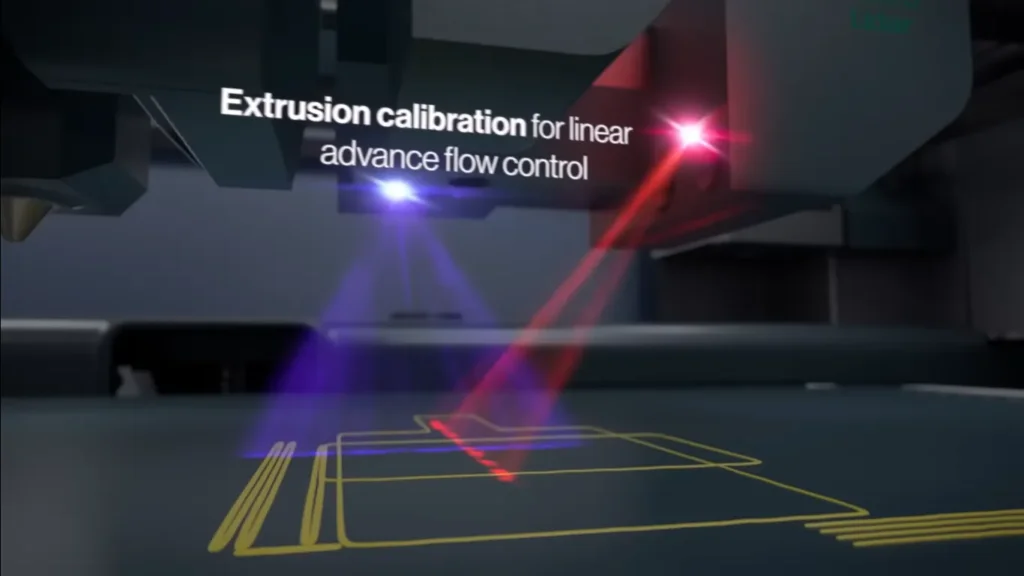

The X1 Carbon includes innovative features like automated calibration, flow rate adjustments, RFID filament recognition and defect detection through its lidar system. The printer automates many aspects of the printing process, making it accessible to users with minimal technical knowledge.

The K2 Plus introduces advanced features like carbon filtration for microplastic emissions, RFID filament recognition, and a unique front design with integrated filament cutting. Its high-temperature capabilities and extensive material compatibility showcase significant innovation in consumer 3D printing.

Winner: Bambu Lab X1 Carbon – While both printers are innovative, the X1 Carbon’s automation and calibration features represent a more significant advancement in user-friendly 3D printing technology.

Camera and Monitoring Systems

The Bambu Lab X1 Carbon features a sophisticated dual camera setup – a down-facing camera for build plate alignment and a chamber camera that enables remote monitoring and AI-based spaghetti failure detection. The mobile app integration allows users to monitor prints from anywhere and creates automatic time-lapse recordings without additional software.

The Creality K2 Plus includes basic camera monitoring capabilities that can be accessed through Creality Cloud for remote print management and monitoring. While functional, it doesn’t offer the advanced AI failure detection features of its competitor.

Winner: Bambu Lab X1 Carbon – Its dual camera system and AI-powered failure detection provide superior monitoring capabilities.

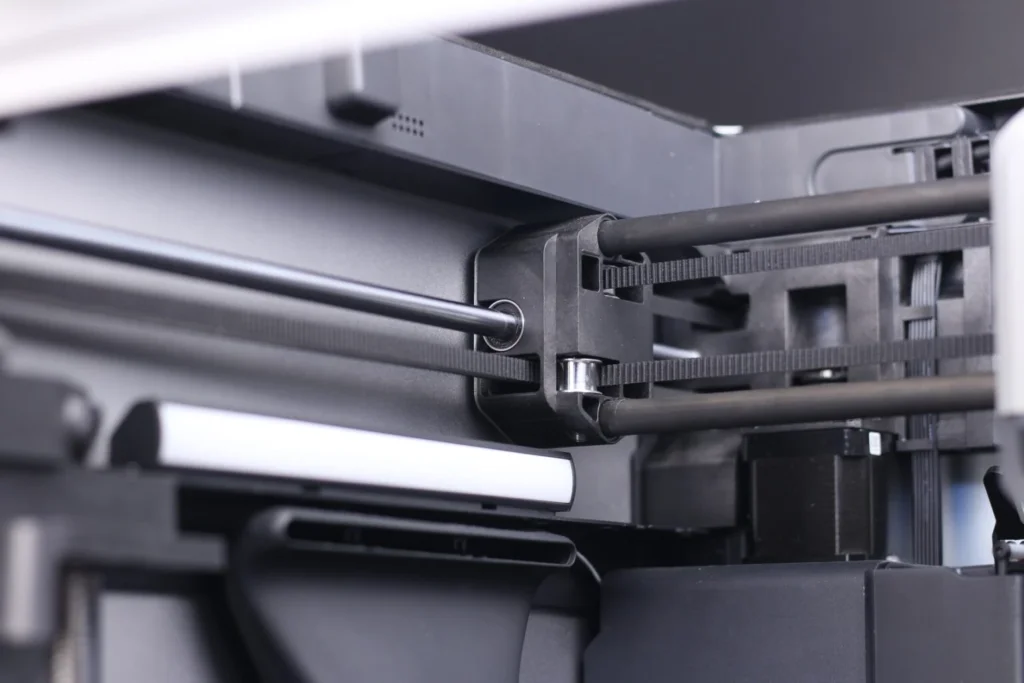

Motion System Technology

The X1 Carbon employs a lightweight carbon fiber gantry in its core XY design, enabling rapid movements with precise control. This design choice contributes to its ability to maintain quality at high speeds, with the carbon fiber components reducing overall moving mass.

The K2 Plus uses closed-loop FOC servo motors in its core XY system, which provides enhanced efficiency and significantly reduced noise compared to traditional stepper motors. The thicker belts and robust cable management system ensure stability even during high-speed operations with heavier builds.

Winner: Tie – Both implement different but equally effective approaches to motion control, with the X1 Carbon focusing on lightweight precision and the K2 Plus on powerful stability.

Bed Technology and Adhesion

The Bambu Lab X1 Carbon uses a dual auto-bed leveling system, combining lidar and analog force sensors to ensure precise and consistent bed leveling. However, it relies on a single Z motor, which can limit its ability to achieve true bed tramming, potentially requiring manual adjustments in some cases.

The Creality K2 Plus, in contrast, employs dual Z motors assisted by four linear rods, providing a more robust system for leveling and maintaining bed alignment over time. Its 5mm thick aluminum heatbed, paired with an active tilt calibration system, ensures excellent adhesion and stability for prints, particularly for larger and more complex builds.

Additionally, the K2 Plus’s 350mm bed size benefits from compatibility with a wide range of aftermarket build surfaces, allowing users to customize the bed material to suit their needs. This flexibility gives it an edge for users who frequently experiment with different materials or require specialized bed finishes.

Winner: Creality K2 Plus – Its dual Z motors, active tilt calibration, and compatibility with aftermarket build surfaces make it superior in bed stability and versatility.

Production Capabilities

The X1 Carbon has proven effective for small business use, with users successfully producing items for Etsy shops and other commercial applications. Its reliability and consistent output make it suitable for small-batch production, though its smaller build volume can be limiting.

The K2 Plus excels in batch production scenarios due to its large build volume, allowing multiple parts to be printed simultaneously. The heated chamber and robust construction make it particularly well-suited for industrial-grade materials and extended production runs.

Winner: Creality K2 Plus – Its larger build volume and industrial-grade features make it more suitable for serious production work.

Long-Term Reliability

The Bambu Lab X1 Carbon has proven its reliability through extensive testing periods. While early beta units showed some issues, production models demonstrate remarkable consistency. After logging over 300 hours of print time, users report that initial challenges like nozzle clogs and filament jams largely disappear once operators switch to Bambu Lab’s recommended filaments. The carbon fiber gantry maintains its rigidity impressively over time, while the build plates show minimal wear even after months of heavy use. The all-metal hot end continues to perform reliably with basic maintenance routines.

The Creality K2 Plus brings industrial-grade durability to the consumer market. Its die-cast aluminum frame shows exceptional resistance to wear and vibration, while the thick aluminum bed maintains perfect flatness through repeated heating cycles. The FOC closed-loop motors demonstrate unwavering precision even after extended use. However, the CFS system requires regular attention due to multi-color purging requirements. The larger build volume puts additional stress on components, making preventive maintenance particularly important. Early adopter feedback indicates that firmware updates have successfully addressed initial software quirks, while the carbon filtration system maintains its effectiveness through extended use. Regular calibration sessions keep print quality consistent.

Winner: Creality K2 Plus – Its industrial-grade construction and robust components edge out the competition for long-term durability, though both machines demonstrate impressive reliability.

Print Quality In-Depth

The Bambu Lab X1 Carbon excels in precision printing, consistently achieving 0.1mm layer heights even at high speeds. The dual auto-bed leveling system, enhanced by lidar assistance, delivers exceptional first layer adhesion. When printing complex geometries, the machine handles overhangs up to 60 degrees without support structures, while managing clean bridging spans up to 50mm. Its multi-material performance shines through clean color transitions and minimal waste. The printer handles PLA with outstanding surface finish, PETG with excellent layer adhesion, TPU with minimal stringing, and ABS with well-controlled warping thanks to the enclosed design. Surface quality remains impressive at standard speeds, though some artifacts may appear when pushing maximum speeds of 500mm/s. Flat surfaces showcase particularly clean top layers.

The Creality K2 Plus demonstrates remarkable versatility across different print scenarios. It maintains consistent 0.12mm layer heights, while excelling at thicker layers between 0.2-0.3mm with exceptional structural strength. The rigid frame particularly benefits tall prints, eliminating the wobble that often plagues larger printers. The dual-side cooling system enables impressive overhang performance, while support structures remove cleanly. Where this printer truly stands out is in handling advanced materials. The high-temperature capabilities up to 350°C open up possibilities with carbon fiber composites, polycarbonate, and engineering-grade nylons. The heated chamber proves essential for perfect ASA and ABS prints, eliminating warping even on large parts. Surface quality remains excellent at standard speeds, though pushing to maximum 600mm/s speeds can impact finish quality. The printer particularly excels at large, flat surfaces, making it ideal for industrial prototypes and functional parts.

Winner: Bambu Lab X1 Carbon – While both printers deliver excellent quality, the X1 Carbon’s superior precision at high speeds and more consistent performance across various print types gives it the edge in overall print quality. However, the K2 Plus takes the lead specifically for industrial materials and large-format printing.

Value Proposition

The price difference between these machines is significant. The X1 Carbon with AMS comes in at around $1,449, while the K2 Plus with CFS is priced at approximately $1,499. Given the K2 Plus’s larger build volume and expandable color system, it offers impressive value for those who need these features.

However, the X1 Carbon’s more refined user experience and superior out-of-the-box performance might make it a better value for users who prioritize reliability and ease of use over build volume. The quality of the included software and the maturity of the ecosystem are significant factors to consider.

Winner: Tie – Both printers offer good value for their target users, with the choice depending on individual needs.

Final Verdict

After extensive testing, both printers have proven themselves capable machines that push the boundaries of what’s possible in consumer 3D printing. The Bambu Lab X1 Carbon edges out as the overall winner, primarily due to its more refined user experience, superior print quality at high speeds, and more polished software ecosystem. It’s the better choice for most users, especially those new to 3D printing or those who prioritize reliability and ease of use.

However, the Creality K2 Plus, makes for a great second option, especially users who need to work with a larger build volume or plan to work with high-temp materials. Its expandable color system and robust construction make it an excellent choice for more specialized applications.

The competition between these two printers has pushed the entire industry forward, and users are the ultimate winners. Whether you choose the X1 Carbon’s refinement or the K2 Plus’s versatility, you’ll be getting a capable machine that represents the cutting edge of consumer 3D printing technology.

The Bambu Lab X1 Carbon features a 256mm cubic build volume and weighs around 31 pounds with the AMS installed, making it relatively manageable for home or office spaces. In contrast, the Creality K2 Plus is significantly larger with a 350mm cubic build volume and weighs about 99 pounds, requiring more substantial space planning and potentially reinforced surfaces for placement. This size difference impacts not just workspace requirements but also the types of projects each printer can handle.

The X1 Carbon employs an Automatic Material System (AMS) that handles up to four colors with notably efficient color transitions and minimal waste. Its color-switching performance works well right out of the box, requiring little tweaking. The K2 Plus takes a different approach with its Color Filament System (CFS), which can theoretically support up to 16 colors when fully expanded. It includes sophisticated features like RFID filament recognition and humidity monitoring, though it typically needs more fine-tuning to achieve optimal color transitions.

The Bambu Lab X1 Carbon achieves speeds up to 500mm/s and consistently delivers clean prints even at high speeds, thanks to its refined motion system and lightweight toolhead. It can produce a quality Benchy in about 15 minutes. The K2 Plus boasts slightly higher speeds up to 600mm/s and particularly excels with larger prints due to its rigid frame construction. While it can complete a Benchy in 14 minutes, it often requires more tuning to maintain quality at maximum speeds. The X1 Carbon generally offers better out-of-the-box performance, while the K2 Plus shines with larger, more substantial prints.

The X1 Carbon features a 300°C nozzle temperature capability and a heated bed reaching 110°C at 220V, making it suitable for materials like PLA, ASA, and carbon fiber-infused nylon. Its enclosed, though not actively heated, chamber provides adequate environmental control for most materials. The K2 Plus offers superior thermal capabilities with a heated bed reaching 180°C and an actively heated chamber, making it particularly well-suited for high-temperature materials like ABS and ASA. Its robust thermal management system gives it an edge for demanding industrial materials.

The X1 Carbon utilizes Bambu Studio, a modified version of PrusaSlicer, offering a refined, user-friendly interface with advanced features like AI-powered failure detection and sophisticated mobile app integration. Its time-lapse recording capabilities and comprehensive monitoring system make it particularly appealing for users who value automation and ease of use. The K2 Plus runs on Creality Print, which, while less polished, provides good functionality and maintains an open-source friendly approach. It offers basic camera monitoring through Creality Cloud and solid connectivity options, though its monitoring capabilities aren’t as sophisticated as the X1 Carbon’s.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.

The X1 can do 16 colors, and doesn’t have an active heater.

Stopped reading after that.

You’re right—the Bambu Lab X1C doesn’t come with an active heater by default. While it supports multi-color printing, the lack of a heater can affect print consistency with certain materials in cooler environments.

Great. I was looking for a good comparison and I find it. Congratulations. Your article is good and precise for my own needs. I’m was looking for printing large scale models and enough precision. 🙂

The Bambulab machine has a single z motor that cannot deliver true bed tramming whereas the K2 actually has dual Z motors and can automatically level out the bed to a degree.

There are also tones of aftermarket build surfaces at 350mm size that will work on it, I feel the bed section is not entirely correct.

Thank you for your feedback! You’re absolutely right—while the Bambu Lab X1 Carbon has advanced dual auto-bed leveling, its reliance on a single Z motor does limit true bed tramming capabilities. On the other hand, the Creality K2 Plus stands out with its dual Z motors and linear rods, providing more robust bed leveling. We’ve also updated the section to highlight the wide availability of aftermarket build surfaces for the K2 Plus’s 350mm bed size. Your input helps us improve the accuracy of our comparisons—much appreciated! 😊

Small mistake on your key features for the K2 “Key Features: 256 × 256 × 256 mm³”

Thank you for your comment! We have already corrected this small mistake. Your feedback helps us to improve our work. 😊

Big Thanks for this. But the comparaison should be between The Creality K2 plus VS Bambu Lab X1E lol

Thank you for your comment! 😊 A comparison between the Creality K2 Plus and the Bambu Lab X1E would definitely be interesting—stay tuned, as we’re working on it! 🚀