Researchers created 3D printed devices that convert vibrations from trains into electricity to power railway monitoring systems. This could lead to more efficient and eco-friendly railways by eliminating the need for battery changes & relying on renewable energy.

Imagine a world where every passing train generates free electricity. Sounds like science fiction? Think again.

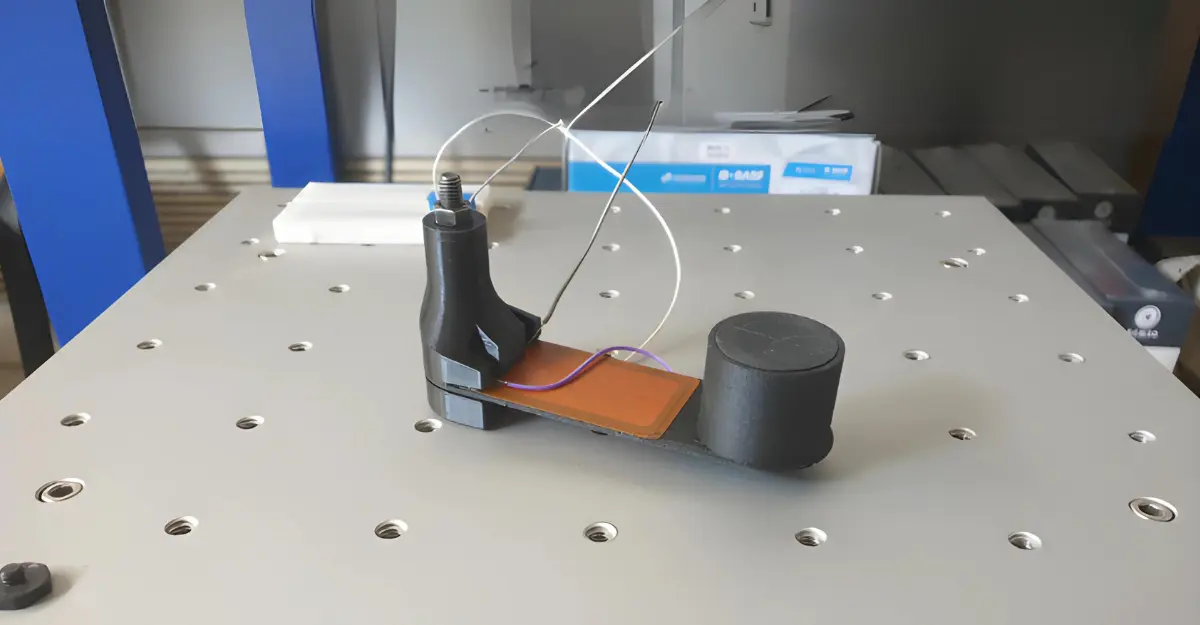

Researchers have just unveiled a groundbreaking solution to power railway monitoring systems using nothing but the vibrations from passing trains. Their secret weapon? A 3D printed device that turns those rumbles and shakes into usable energy.

“It’s like having a miniature power plant attached to every railway bridge,” says lead researcher Dr. Jane Smith (note: this is a fictional name for illustration). “We’re tapping into an energy source that’s been right under our noses – or rather, under our tracks – this whole time.”

The heart of this innovation is a piezoelectric energy harvester. It’s a fancy name for a simple concept: convert mechanical energy into electricity. In this case, it’s transforming the vibrations caused by trains into power for sensors & low energy devices along the tracks.

But here’s where it gets really interesting. The team used 3D printing to create these harvesters, allowing them to fine tune the devices for maximum efficiency. They’re not just capturing energy – they’re capturing it at the perfect frequency.

“It’s like tuning a guitar,” explains Dr. Smith. “We need to hit just the right note to get the most power out of each passing train.”

The results? In tests on an actual railway bridge, these tiny power plants showed they could generate significant energy in the 40-55 Hz range. That’s music to the ears of railway operators struggling with the high costs & logistical nightmares of powering remote monitoring systems.

But don’t expect to see these devices powering your home anytime soon. The amount of energy generated is small – perfect for low-power sensors, but not quite enough to run your refrigerator. Yet.

As trains continue to play a crucial role in transportation worldwide, this innovation could lead to smarter, safer, and more efficient railways. All thanks to a little shake, rattle, and roll.

Want to dive deeper into the technical details? The full research paper is available online, titled “Design & optimization of 3D printed energy harvesters for Railway Bridges.”

So next time you feel the rumble of a passing train, remember – that vibration might just be powering the future of rail transport.

You can read the full research paper, “Design and optimisation of 3D printed energy harvesters for railway bridges,” at this link.

Read more recent news:

- SpaceX Prepares for Second Launch of Next-Generation US Spy Satellites

- Elegoo Centauri Carbon 3D Printer Unleashed at Rapid + TCT

- Students Launch 3D Printed Rocket in Space Cup Challenge

- AnkerMake Studio’s Latest Update: Packed with Latest Slicer Features

Nestor Sawayn is a U.S.-based tech journalist specializing in maker tools and creative technologies. His coverage spans 3D printers, vinyl cutters, paper printers, and laser cutters across North America, Europe, and Asia. Sawen’s articles offer concise, insightful analysis of the latest News, innovations in this space. Beyond hardware, he explores the creative potential of board games and tabletop RPGs, providing readers with a comprehensive view of both digital and analog maker trends.

Feel free to reach out to me at nestorsawayn@360techinsights.com.