The Bambu P1S vs Prusa MK4 comparison presents two leading 3D printers with distinct strengths. The Bambu P1S offers faster printing speeds, reaching up to 20,000 mm/s² acceleration, and multi-color capabilities with its AMS system. It’s also more affordable at $599 for the base model. The Prusa MK4, priced at $1,099, excels in print quality and reliability, with a strong reputation for long-term support and an open-source design. Both printers feature easy setup and automatic calibration, making them suitable for beginners & experts alike. The choice between the Bambu P1S vs Prusa MK4 ultimately depends on individual priorities such as speed, multi-color printing, or customization options.

Bambu Lab P1s

Released: 2023 Aug

Build Volume: 256 × 256 × 256 mm³

Price Range: $599.00 to $849.00

The most notable differences between the two printers are in their build volumes, overall dimensions, and some key features. The Bambu P1S offers a slightly larger cubic build volume and comes with an integrated enclosure and camera. It also boasts higher maximum print speeds and acceleration rates.

The Prusa MK4, while having a slightly smaller build volume, offers a higher maximum bed temperature and a larger touchscreen display. It’s also significantly lighter than the P1S, which could be an advantage for users with space constraints.

Both printers support a wide range of materials and offer similar layer height capabilities, indicating that they can produce prints with comparable levels of detail. The choice between these two will likely come down to specific feature preferences and use cases, which we’ll explore in more depth throughout this article.

Bambu P1S vs Prusa MK4 Specifications Chart

| Feature | Bambu P1S | Prusa MK4 |

|---|---|---|

| Build Volume | 256 x 256 x 256 mm | 250 x 210 x 220 mm |

| Printer Dimensions | 389 x 389 x 457 mm | 500 x 550 x 400 mm |

| Weight | 12.95 kg | 7 kg |

| Max Nozzle Temperature | 300°C | 290°C |

| Max Bed Temperature | 100°C | 120°C |

| Layer Height | 0.05 – 0.30 mm | 0.05 – 0.30 mm |

| Max Print Speed | 500 mm/s | Not specified (2x MK3S+) |

| Max Acceleration | 20,000 mm/s² | Not specified |

| Filament Diameter | 1.75 mm | 1.75 mm |

| Enclosure | Yes | Optional |

| Connectivity | Wi-Fi, Bluetooth, SD Card | Wi-Fi, LAN, USB |

| Camera | Yes | No |

| Display | 2.7-inch color screen | 3.5-inch color touchscreen |

| Filament Sensor | Yes | Yes |

| Power Loss Recovery | Yes | Yes |

Setup and Assembly

One of the most significant differences between the Bambu P1S and the Prusa MK4 lies in their setup processes, which cater to different user preferences and skill levels.

Bambu P1S:

The Bambu P1S is designed with user convenience in mind, offering a truly plug-and-play experience. According to the product information, setup can be completed in as little as 15 minutes. This rapid setup process involves:

- Unboxing the printer

- Plugging it in

- Running a quick self-test

- Loading filament

The P1S comes pre-assembled and pre-calibrated, which means users can start their first print almost immediately after unboxing. This approach is particularly appealing to beginners or those who prioritize convenience over the learning experience of building a printer.

The enclosed design of the P1S also simplifies the setup process, as users don’t need to consider environmental factors like drafts that might affect open-frame printers. The integrated Wi-Fi connectivity further streamlines the setup, allowing users to quickly connect the printer to their network for remote control and monitoring.

Prusa MK4:

In contrast, the Prusa MK4 is available both as a pre-assembled unit and as a kit. The kit version, which is a hallmark of the Prusa experience, requires assembly by the user. This process typically takes around 8 hours for a first-time builder, though experienced makers might complete it more quickly.

The assembly process includes:

- Building the frame and axis systems

- Installing the electronics

- Mounting the extruder and hotend

- Setting up the bed and calibration system

While this might seem daunting to some, Prusa provides extremely detailed, step-by-step instructions in their assembly manual. Many users report that the assembly process is educational & enjoyable, providing a deep understanding of how the printer works.

The advantage of this strategy is that consumers learn detailed details about the parts and functionality of their printer, which may be very helpful for future maintenance and updates. It also allows for a degree of customization during the build process.

For those who prefer a ready-to-use solution, Prusa does offer a pre-assembled version of the MK4, though it comes at a higher price point.

Comparison and Considerations

The choice between these two setup approaches largely depends on the user’s goals and preferences:

- Time Investment: The P1S offers near-immediate gratification, while the MK4 kit requires a significant time investment upfront.

- Learning Curve: Building the MK4 provides a steeper initial learning curve but potentially easier long-term maintenance.

- Customization: The MK4’s kit form allows for some customization during assembly, while the P1S is more of a fixed configuration.

- User Experience: Some users find great satisfaction in building their own printer, while others prefer to focus solely on printing.

Ultimately, the Bambu P1S is likely to appeal more to those who want to start printing as quickly as possible or who are less interested in the technical aspects of 3D printer construction. The Prusa MK4, particularly in its kit form, is better suited to those who enjoy a hands-on approach and want to gain a deeper understanding of their machine.

Printing Features

When it comes to the core functionality of 3D printing, both the Bambu P1S and the Prusa MK4 offer impressive capabilities, each with its own strengths. Let’s break down their printing features in detail.

1. Build Volume and Aesthetics

Bambu P1S:

- Build Volume: 256 x 256 x 256 mm

- Enclosed design gives a sleek, professional appearance.

- Smaller overall footprint (389 x 389 x 457 mm) may be beneficial for users with limited space.

Prusa MK4:

- Build Volume: 250 x 210 x 220 mm

- Open frame design allows for easy observation of prints in progress.

- Larger overall footprint (500 x 550 x 400 mm) but lighter weight (7 kg vs 12.95 kg for the P1S).

The P1S offers a slightly larger build volume, especially in terms of height, which could be beneficial for users who frequently print tall objects. Its enclosed design also contributes to a more polished aesthetic, which might be preferred in office or living space environments.

The MK4’s open design, while less sleek, offers better visibility of the printing process, which can be educational and satisfying for many users. Its lighter weight also makes it easier to move or reposition if needed.

Practical Implications:

- P1S: Better suited for environments where appearance matters or where protection from drafts is important.

- MK4: More suitable for users who enjoy watching the printing process or need frequent access to the print bed.

2. Print Quality

Both printers are capable of producing high-quality prints, but they achieve this in slightly different ways.

Bambu P1S:

- Layer Height: 0.05 – 0.30 mm

- The P1S uses a direct-drive extruder system, which provides precise control over extrusion and retraction, particularly beneficial for flexible filaments.

- Its enclosed design helps maintain consistent temperature, potentially reducing warping and improving layer adhesion, especially for materials like ABS.

- Users report excellent surface finish and minimal stringing, even at high speeds.

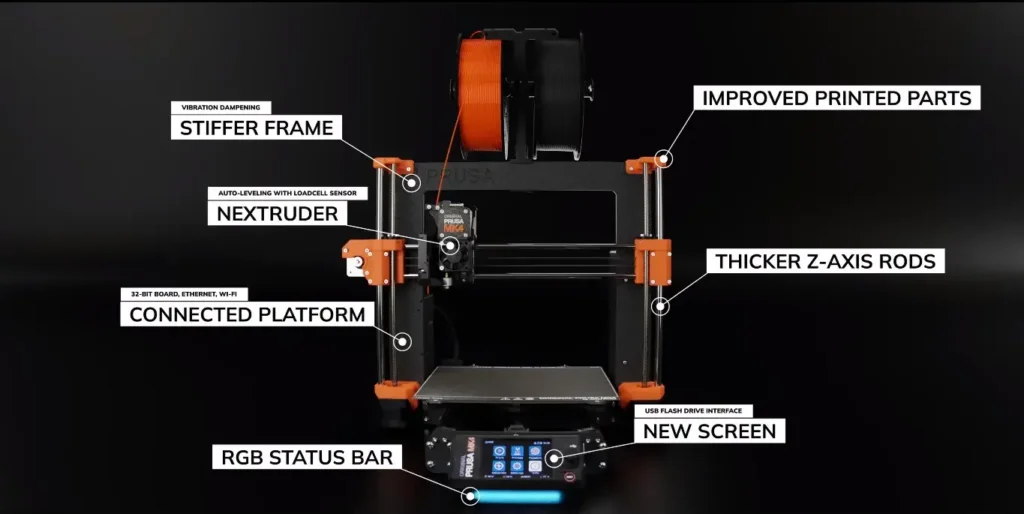

Prusa MK4:

- Layer Height: 0.05 – 0.30 mm

- The MK4 uses the new “Nextruder” extruder system, which is designed to handle a wide range of materials efficiently.

- It features improved 0.9° stepper motors, which Prusa claims help eliminate vertical fine artifacts on prints.

- The MK4 is known for its exceptional print quality, particularly in terms of dimensional accuracy & surface finish.

Both printers offer comparable layer height capabilities, indicating that they can produce similar levels of detail. However, the enclosed nature of the P1S might give it a slight edge when printing materials prone to warping or temperature sensitivity.

3. Speed and Performance

This is an area where the two printers show significant differences.

Bambu P1S:

- Max Print Speed: 500 mm/s

- Max Acceleration: 20,000 mm/s²

- The P1S is marketed as a high-speed printer, capable of printing a Benchy (a common 3D printing benchmark model) in just 18 minutes.

- It uses advanced control algorithms, vibration compensation, and pressure advance technologies to maintain quality at high speeds.

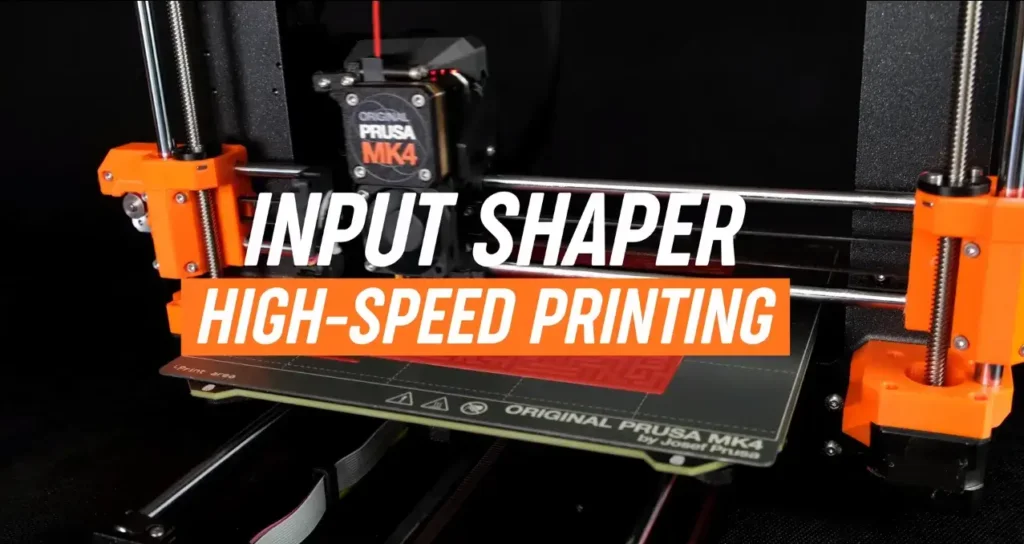

Prusa MK4:

- Max Print Speed: Not explicitly stated, but advertised as twice as fast as the MK3S+

- The MK4 uses Input Shaper and Pressure Advance technologies to increase print speed while maintaining quality.

- While not as fast as the P1S on paper, the MK4 is still capable of impressive speeds, especially compared to its predecessors.

The Bambu P1S clearly has the edge in terms of raw speed capabilities. However, it’s important to note that maximum speeds are often theoretical and may not be achievable for all print types while maintaining quality. Real-world performance may be closer between the two printers, depending on the specific model and settings used.

4. Filament Handling

Both printers are designed to work with a wide range of materials, but they approach filament handling differently.

Bambu P1S:

- Compatible with PLA, PETG, TPU, ABS, ASA, PA, PC, PVA, and more.

- Features an optional AMS (Automatic Material System) for multi-color printing with up to 4 filaments.

- The enclosed design is particularly beneficial for materials like ABS that are sensitive to temperature fluctuations.

Prusa MK4:

- Compatible with PLA, PETG, ABS, ASA, PA, PC, HIPS, PVA, and more.

- Can be upgraded with the MMU3 (Multi-Material Upgrade) for printing with up to 5 filaments.

- The open design may require an enclosure (sold separately) for optimal results with some materials.

Both printers offer excellent material compatibility. The P1S’s integrated enclosure gives it an advantage for temperature-sensitive materials out of the box, while the MK4’s MMU3 upgrade allows for slightly more complex multi-material prints.

5. Calibration and Software

The user experience of a 3D printer is greatly influenced by its calibration process and the software used to prepare prints.

Bambu P1S:

- Uses a “Loadcell” sensor for automatic bed leveling, which Bambu claims works on all types of print surfaces.

- Comes with Bambu Studio, a customized version of PrusaSlicer tailored for Bambu printers.

- Offers one-click printing and claims to handle all calibrations automatically.

Prusa MK4:

- Features automatic calibration and mesh bed leveling.

- Uses PrusaSlicer, a powerful and well-regarded open-source slicer software.

- Includes features like stuck filament detection and a “Cancel Object” function in the printer menu.

Both printers offer user-friendly calibration processes and capable slicing software. The P1S seems to emphasize simplicity and automation, while the MK4 provides a balance of automation and user control.

In summary, both the Bambu P1S and Prusa MK4 offer impressive printing features. The P1S stands out for its high-speed capabilities and integrated enclosure, while the MK4 impresses with its proven track record of print quality and open-source flexibility. The choice between them will depend on whether users prioritize raw speed and simplicity or fine control and customization in their printing process.

6. Noise Levels

Bambu P1S:

- Enclosed design naturally reduces operational noise.

- Uses closed-loop control for fans, potentially reducing noise further.

- Some users report that while quieter than open printers, it’s not silent, especially at high speeds.

Prusa MK4:

- Open design may result in more noticeable operational noise.

- Implements “Stealth Mode” for quieter operation, though this may reduce print speed.

- Users report significant noise reduction compared to previous Prusa models.

The enclosed design of the P1S gives it a natural advantage in terms of noise reduction. This could be a crucial factor for users who plan to operate their printer in living spaces or during night hours. However, it’s worth noting that at very high speeds, even the P1S can produce noticeable noise.

The MK4, while not as inherently quiet as the P1S, has made strides in noise reduction compared to its predecessors. The Stealth Mode option provides flexibility for users who prioritize quiet operation over maximum speed.

Considerations:

- P1S: Better suited for shared spaces or noise-sensitive environments.

- MK4: May require additional measures (like an aftermarket enclosure) to achieve similar noise levels to the P1S.

In summary, the Bambu P1S offers a more streamlined, beginner-friendly user experience with its enclosed design and emphasis on automation. It’s particularly well-suited for users who prioritize ease of use and minimal noise. The Prusa MK4, while requiring a bit more user engagement, offers a more hands-on experience that many enthusiasts prefer. Its open design and extensive community support make it an excellent choice for users who enjoy understanding & customizing their printer. The choice between the two will largely depend on the user’s preferences for automation versus hands-on control, and their specific needs in terms of build volume, noise levels, and aesthetics. Both printers offer compelling user experiences, catering to different segments of the 3D printing community.

User Experience

The overall user experience of a 3D printer encompasses many factors beyond just print quality. Let’s compare how the Bambu P1S and Prusa MK4 perform in terms of ease of use, build volume practicality, and noise levels.

Ease of Use

Bambu P1S:

- Designed for out-of-the-box functionality with minimal setup required.

- Automatic calibration and one-click printing simplify the process for beginners.

- The integrated enclosure reduces the need for environmental considerations.

- Wi-Fi connectivity allows for easy remote monitoring and control.

- The built-in camera enables users to check print progress remotely.

Prusa MK4:

- Available as a kit or pre-assembled, catering to different user preferences.

- Automatic calibration features, but may require more user intervention than the P1S.

- Open design allows for easy access to components for maintenance and upgrades.

- Wi-Fi and ethernet connectivity for remote printing and monitoring.

- Extensive documentation and a large community provide support for troubleshooting.

The P1S seems to have a slight edge in terms of initial ease of use, especially for beginners. Its enclosed design and emphasis on automation make it more of a “plug-and-play” solution. However, the MK4’s open design and extensive documentation make it more accessible for users who want to understand and tinker with their printer.

Learning Curve:

- P1S: Shorter initial learning curve, but may limit deeper understanding of 3D printing mechanics.

- MK4: Steeper initial curve (especially if assembled from a kit), but potentially easier long-term maintenance and troubleshooting due to familiarity with the printer’s components.

Maintenance:

- P1S: Enclosed design may make some maintenance tasks more challenging.

- MK4: Open design allows for easy access to all components for maintenance and upgrades.

Additional Features

Bambu P1S:

The P1S comes with several notable additional features that set it apart:

Built-in Enclosure:

As mentioned earlier, the enclosed design is a significant feature of the P1S. It provides several benefits:

- Maintains a stable printing environment, crucial for materials like ABS

- Reduces noise during operation

- Keeps potentially harmful fumes contained (in conjunction with the carbon filter)

- Protects the print from drafts and dust

Integrated Camera:

The built-in camera offers several advantages:

- Remote monitoring of print progress

- Creation of timelapse videos

- Potential for print error detection (with future software updates)

Automatic Material System (AMS):

While an optional add-on, the AMS is worth mentioning:

- Allows for multi-color printing with up to 4 filaments

- Automated filament switching

- Filament dry box functionality

Prusa MK4:

The MK4, true to Prusa’s philosophy, focuses on upgradability and customization:

Upgradability:

- Easy to upgrade from previous Prusa models

- Modular design allows for easy part replacement and upgrades

Customization Options:

- Open design facilitates modifications and additions

- Large ecosystem of community-designed upgrades and modifications

Multi-Material Upgrade (MMU3):

Like the P1S’s AMS, the MMU3 is an optional add-on:

- Allows printing with up to 5 materials

- Compatible with water-soluble support materials

SuperPINDA Sensor:

- Advanced bed leveling sensor

- Temperature-independent for consistent performance

Comparison:

The additional features of each printer reflect their overall design philosophies. The P1S focuses on providing a complete, self-contained printing solution with features like the built-in enclosure and camera. These additions make it particularly attractive for users who want a hassle-free, all-in-one printing experience.

The MK4, on the other hand, emphasizes upgradability and customization. Its open design and modular construction make it ideal for users who enjoy tinkering with their printer and adapting it to their specific needs over time.

Both printers offer multi-material printing options, which is a significant feature for users interested in creating complex, multi-color prints or using soluble support materials.

The choice between the two in terms of additional features may depend on whether you prefer a more integrated, out-of-the-box solution (P1S) or a more customizable, upgradable platform (MK4).

Community and Support

Bambu P1S:

Community:

- Rapidly growing user base

- Active Facebook groups and Discord channels

- Emerging presence on 3D printing forums

Official Support:

- Comprehensive user manual and setup guide

- Active customer support team

- Regular firmware and software updates

While Bambu Lab is a relatively new player in the 3D printing market, they’ve quickly built a dedicated following. The community around their printers is growing rapidly, with users sharing tips, troubleshooting advice, and custom print profiles.

Prusa MK4:

Community:

- Large, well-established user base

- Active presence on major 3D printing forums and social media

- Extensive library of user-created mods and upgrades

Official Support:

- 24/7 live chat support in multiple languages

- Comprehensive knowledge base and troubleshooting guides

- Regular firmware updates and feature additions

Prusa has been a major player in the 3D printing community for over a decade, and this is reflected in their robust community support. The wealth of user-generated content, from troubleshooting guides to custom mods, is a significant asset for MK4 owners.

Comparison:

In terms of community support, the Prusa MK4 has a clear advantage due to its longer presence in the market. The vast amount of user-generated content and the large, experienced user base can be invaluable resources, especially for newcomers to 3D printing.

However, the Bambu P1S community is growing rapidly and shows a high level of enthusiasm. Early adopters report that the official support from Bambu Lab is responsive and helpful.

Prusa’s 24/7 multilingual support is a standout feature, particularly for users who may need assistance outside of regular business hours. Their extensive knowledge base and troubleshooting guides are also valuable resources.

While Bambu Lab’s support may not be as extensive as Prusa’s yet, they’ve shown a commitment to regular updates and improvements, which bodes well for long-term support.

The choice between the two in this aspect may depend on how much you value a large, established community (MK4) versus being part of a newer, rapidly growing ecosystem (P1S).

Price and Value

Bambu P1S:

Base Price: $599 (as of Oct 2024)

Combo Price (with AMS): $849

Additional Considerations:

- Enclosed design included in base price

- Built-in camera and Wi-Fi

- Optional AMS for multi-color printing ($250)

The P1S offers a compelling value proposition, especially considering its enclosed design and high-speed capabilities. The all-in-one nature of the printer, with features like the built-in camera and Wi-Fi, adds to its value.

Prusa MK4:

Base Price: $1,099 (assembled version, as of July 2024)

Kit Version: $799

Additional Considerations:

- Optional MMU3 for multi-material printing (price varies)

- Enclosure available as separate purchase

- Optional Wi-Fi module

The MK4’s price reflects Prusa’s reputation for quality and reliability. The availability of a kit version provides a more budget-friendly option for those willing to assemble the printer themselves.

- Initial Cost: The P1S has a lower entry price, making it more accessible for beginners or those on a tighter budget.

- Long-term Value: The MK4’s open-source nature and robust upgrade path may offer better value over time for users who plan to modify or expand their printer’s capabilities.

- Included Features: The P1S offers an enclosed design and built-in camera as standard features, while these are optional extras for the MK4.

- Upgrades: The MK4’s MMU3 multi-material upgrade ($299) is comparable in price to Bambu’s AMS, but offers more flexibility in terms of filament choices.

- Ecosystem: Prusa’s in-house filament production (Prusament) and discount program for printer owners can contribute to long-term cost savings.

The P1S offers excellent value for users seeking a high-speed, enclosed printer with multi-color capabilities right out of the box. Its AMS system and integrated features add significant value to the package.

The MK4, while more expensive upfront, provides value through its reputation for reliability, extensive community support, and long-term upgradeability.

For beginners or those prioritizing ease of use, the P1S may offer better immediate value. However, for enthusiasts or professionals who value long-term flexibility and community-driven development, the MK4’s higher price may be justified by its potential for customization and upgrades.

| ALSO READ |

|---|

| Flashforge Adventurer 5M Pro 3D Printer Review |

| What can you make with a 3d Printer to Sell and what will be your strategy? |

Ultimately, the best value depends on individual needs, printing goals, and budget constraints. Both printers offer strong value propositions for their respective target audiences.

Conclusion

The Bambu P1S vs Prusa MK4 represents two different philosophies in the world of 3D printing, each excelling in its own way.

The Bambu P1S stands out with its user-friendly approach, offering a plug & play experience that’s hard to beat. Its enclosed design, high-speed printing capabilities & integrated features like the AMS and built-in camera make it an attractive option for those who prioritize convenience & quick setup. The P1S is particularly well-suited for users who want a hassle free printing experience & impressive out-of-the-box performance.

On the other hand, the Prusa MK4 embodies the spirit of open-source innovation & customization. Its modular design, extensive upgrade options & strong community support make it ideal for enthusiasts who enjoy tinkering and want the flexibility to modify their printer over time. The MK4’s reputation for reliability & print quality is well-deserved, making it a solid choice for both hobbyists & professionals.

For beginners or those seeking a streamlined experience, the Bambu P1S offers an impressive package that’s ready to go right out of the box. However, for users who value long-term flexibility, community-driven development, and the ability to deeply customize their machine, the Prusa MK4 remains a top contender.

Ultimately, the choice between these two excellent printers will depend on your specific needs, budget & approach to 3D printing. Both machines are capable of producing high-quality prints, but they cater to different user preferences & philosophies within the 3D printing community.

FAQs:

Which printer is faster, the Bambu P1S or Prusa MK4?

The Bambu P1S is generally faster, with acceleration up to 20,000 mm/s² and the ability to print a benchy in 18 minutes. The Prusa MK4, while improved over its predecessor, is not as fast as the P1S. However, the MK4 has received firmware updates to increase its speed and maintains high print quality at faster speeds.

How do the print qualities of the Bambu P1S vs Prusa MK4 compare?

Both printers offer excellent print quality, but they have different strengths. The Bambu P1S is known for its speed while maintaining good quality, especially with multi-color prints using the AMS system. The Prusa MK4 is renowned for its exceptional print quality and reliability, with particular attention to detail & precision, especially for functional parts.

Which printer is easier to set up and use, the Bambu P1S or Prusa MK4?

Both printers are designed for easy setup and use. The Bambu P1S boasts a 15-minute setup time and works “right out of the box” with automatic calibrations. The Prusa MK4 also features plug-and-play functionality with automatic calibration and a user-friendly interface. Both printers are suitable for beginners, but the P1S might have a slight edge in initial setup speed.

What materials can the Bambu P1S and Prusa MK4 handle?

Both printers support a wide range of materials. The Bambu P1S can print PLA, PETG, TPU, ABS, ASA, PA, PC, PVA, and PET. The Prusa MK4 supports PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN, and various composites. Both printers are versatile, but the MK4 might have a slight edge in supporting more specialized materials.

How do the prices of the Bambu P1S and Prusa MK4 compare?

The Bambu P1S is priced at $699 for the base model and $949 for the combo with AMS (multi-color printing). The Prusa MK4 is priced at $1,099 for the assembled version. While the P1S is less expensive, the Prusa MK4 justifies its higher price with its reputation for reliability, long-term support, and open-source design.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.