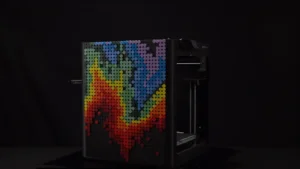

The Elegoo Mercury Plus V3 positions itself as a bridge between basic wash containers and industrial post-processing solutions for resin 3D printing. With its generous processing area and dual-function capabilities, it’s designed to handle everything from small figurines to large format prints from machines like the Saturn 4 Ultra. The enclosed design makes it perfect for home workshops or dedicated printing spaces, especially with its comprehensive UV protection system.

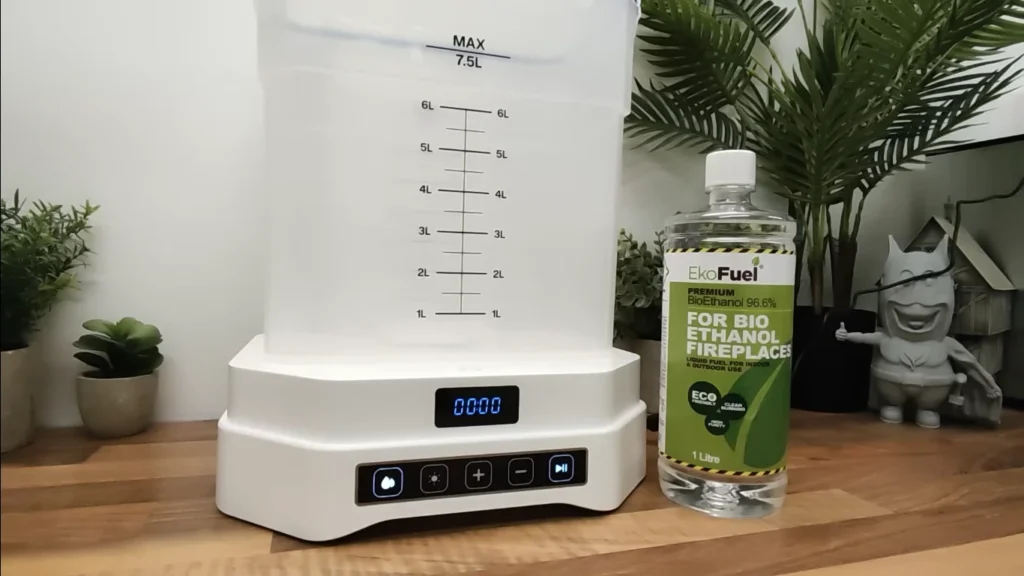

Out of the box, the Mercury Plus V3 comes ready to tackle both washing and curing tasks, though its true potential shines through when working with the complete system. The consolidation of these functions into a single unit, combined with the significantly larger 7.5L capacity (114% more than its predecessor) and expanded curing space (460% increase), makes this an intriguing option for both newcomers and experienced resin printing enthusiasts.

What sets the Mercury Plus V3 apart is its thoughtful design approach to common post-processing challenges. From the adjustable support brackets that accommodate various build plate sizes to the dual cleaning modes, Elegoo has clearly considered real-world usage scenarios. The simplified touch control interface and clear documentation make it accessible even for those new to resin printing, while the enhanced features provide the thoroughness that experienced users demand.

Elegoo Mercury Plus V3

Pros

Dual-function wash and cure

Compact and space-saving design

Enhanced UV light distribution

Large tank for bigger prints

Versatile printer compatibility

Cons

Louder than previous models

Limited to mid-sized prints

Single bucket may wear out

The Package and Setup

Unboxing reveals a nearly fully assembled unit, including the main station with UV curing lights, a washing bucket, curing turntable, cleaning basket, two adjustable brackets, and the necessary power adapter. Everything slots together intuitively, making setup straightforward even for newcomers to resin printing.

A Washing Revolution

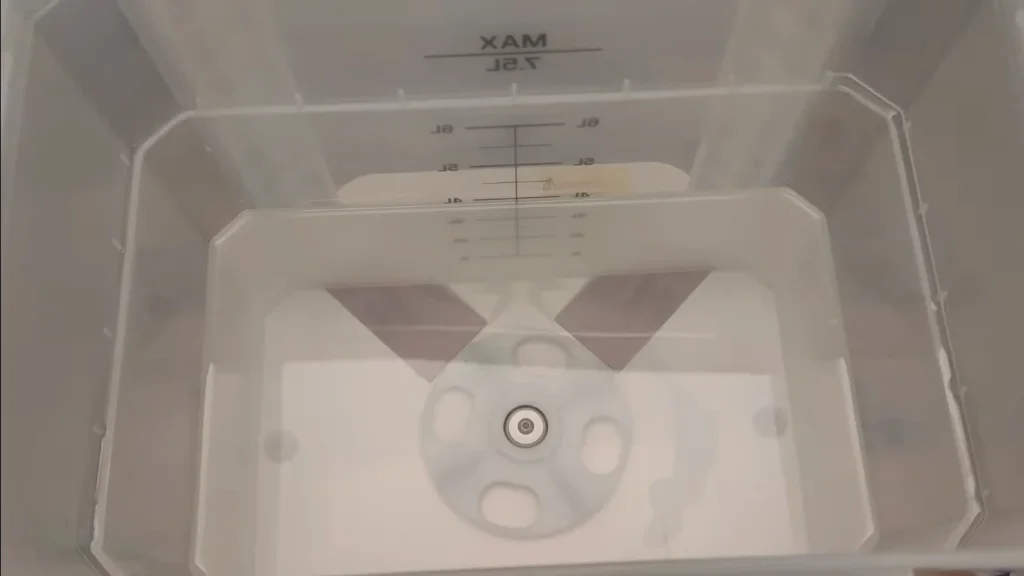

The washing capabilities of the Mercury Plus V3 represent a significant step forward. The new 7.5L cleaning capacity marks a 114% increase over the V2.0 model. This expanded size isn’t just about numbers – it’s about practical functionality. The station offers two distinct cleaning approaches to match your needs.

The basket cleaning mode accommodates prints up to 230mm x 135mm x 260mm once removed from the build plate. If you prefer to clean while your print is still attached to the build plate, the hanging cleaning mode supports dimensions of 214mm x 135mm x 180mm. This flexibility is enhanced by new adjustable support brackets that can handle build plates up to 10 inches – a crucial feature for users of larger format printers.

At the heart of the washing system sits an upgraded POM bearing, designed to create smoother rotation and enhanced water agitation. One particularly noteworthy improvement is the sealed base design of the tank, ensuring your cleaning solution stays where it belongs. However, it’s worth noting that unlike the previous version, V2 buckets aren’t compatible with this new model.

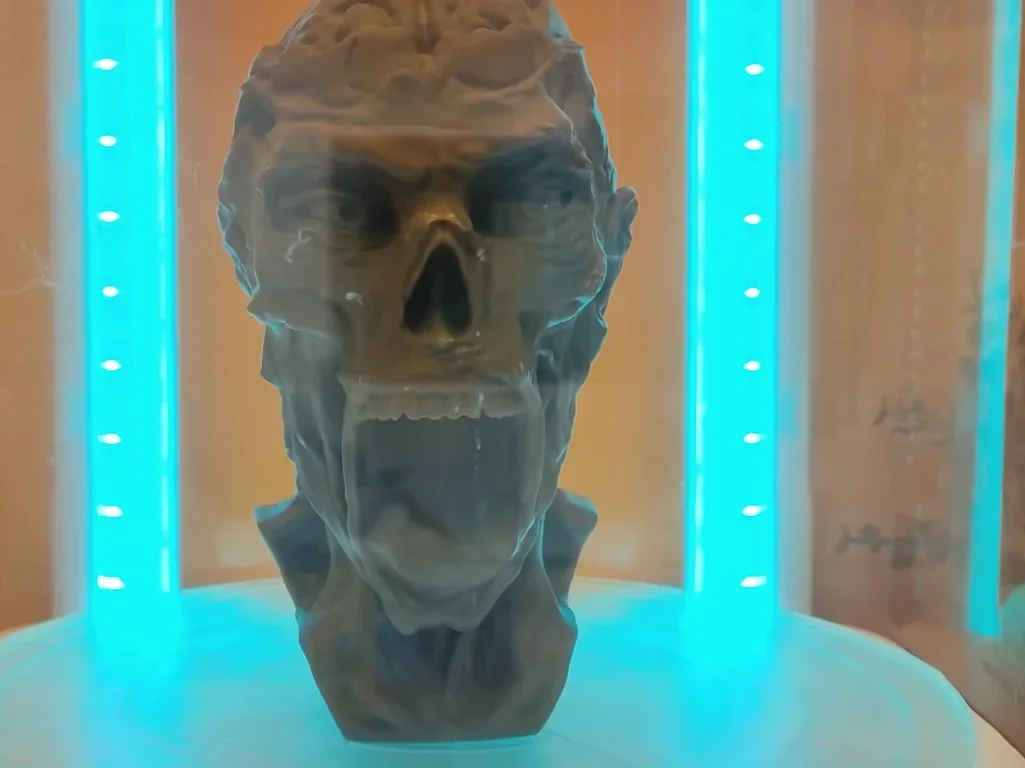

The Curing Evolution

The curing system represents perhaps the most sophisticated aspect of the Mercury Plus V3. It employs 24 powerful 405nm UV lights working in concert with reflective mirrors beneath a transparent turntable. This setup creates a 360-degree curing environment that can handle prints up to 250mm in diameter and 290mm in height – a 460% increase in curing capacity over its predecessor.

For those concerned about safety, the anti-UV cover blocks 99.9% of ultraviolet rays, and a micro switch automatically stops the curing process if the cover is removed. When it comes to curing times, smaller models (under 30mm) typically need about 2 minutes, though complex structures may require additional time.

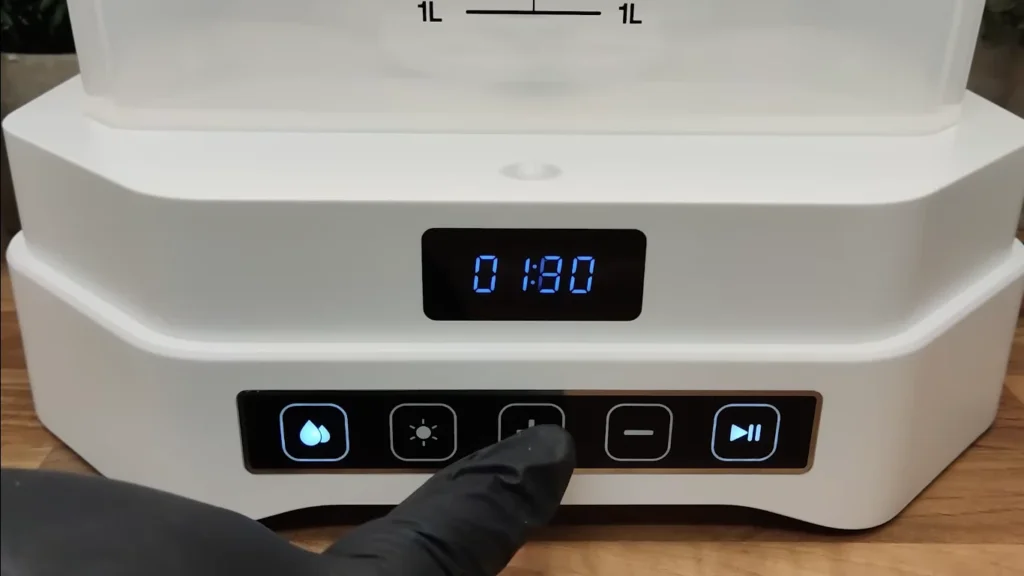

Control Interface and Usability

The touch panel interface is straightforward but effective. You can adjust both washing and curing times in 30-second increments up to 30 minutes. While I would have liked to see preset options for common print sizes, the simple interface means there’s less that can go wrong. The power switch and 24-volt outlet are conveniently located on the right side of the base unit, though the mysterious additional port (possibly for future accessories) remains unused for now.

During my testing period, I developed a workflow that seemed to maximize efficiency: pre-washing larger prints in a separate container of used IPA to remove the bulk of uncured resin, then using the Mercury Plus V3 for the final clean. This approach helps extend the life of your cleaning solution and improves overall results.

Compatibility and Practical Use

The Mercury Plus V3 is officially designed to work with all Elegoo resin printers, but I tested it with several other brands including Anycubic and Phrozen models. The results were consistently good across all tested printers, though owners of the Jupiter series should note that they’ll need to remove prints from the build plate due to size constraints.

The plastic basket design, replacing the metal ones found in earlier models, initially concerned me about longevity. However, after several weeks of regular use, it’s held up well, and the adjustable nature of the brackets actually makes it more versatile than its metal predecessors. The basket handles clear the raised lid even when fully extended, which makes handling wet, resin-covered prints much less messy than with previous models.

Power Consumption and Operation

The unit runs on standard 100-240V power with a 24V/2.5A power adapter, making it suitable for worldwide use. During testing, I monitored power consumption and found it to be reasonable – you’re not going to see a significant impact on your electricity bill from regular use. The machine weighs about 4.7kg (net), making it substantial enough to stay stable during operation but not so heavy that it’s difficult to move when needed.

Elegoo Mercury Plus V3 Specification Chart

| Category | Specification | Details |

|---|---|---|

| Base Unit Dimensions | Length | 302.5mm |

| Width | 302.5mm | |

| Height | 412.5mm | |

| Weight | Net | 4.7 KG |

| Gross (Packaged) | 6.3 KG | |

| Washing Capacity | With Build Plate | 214mm × 135mm × 180mm |

| Basket Mode | 230mm × 135mm × 260mm | |

| Tank Volume | 7.5L (114% larger than V2.0) | |

| Curing Space | Maximum Size | Ø250mm × 290mm |

| UV System | 24 405nm LED lights | |

| Turntable | 360° rotation | |

| UV Protection | 99.9% UV blocking coverage | |

| Power Requirements | Input Voltage | 100-240V 50/60Hz |

| Power Supply | 24V 2.5A | |

| Control System | Interface | Touch button panel |

| Timer Range | 0-30 minutes | |

| Increment | 30-second steps | |

| Cleaning Solution | Compatible Types | IPA, Ethanol, Specialized cleaners |

| Printer Compatibility | Elegoo Models | Saturn 4 Ultra, Mars 5 Series, Most Saturn models |

| Other Brands | Most LCD/DLP/SLA printers (≤10″ build plate) | |

| Package Size | Length | 379mm |

| Width | 379mm | |

| Height | 497mm | |

| Build Plate Support | Bracket System | Adjustable up to 10 inches |

| Mounting Options | Direct hang or basket cleaning | |

| Safety Features | UV Protection | Auto-shutoff when cover removed |

| Operation | Sealed wash tank with secure lid | |

| Warranty | Standard Coverage | 1 year |

| Return Period | 14 days | |

| Price | Regular | $162.00 USD |

| Pre-order | $129.99 USD |

The Cleaning Solution Question

For those working with water-washable resins, Elegoo recommends adding alcohol or IPA during the cleaning process for optimal results. While water-washable resins can technically be cleaned with water alone, the addition of alcohol-based solutions tends to yield better cleaning outcomes in this machine.

Value and Support

Beyond the hardware itself, Elegoo backs the Mercury Plus V3 with a one-year warranty and 14-day return policy. The company also advertises lifetime support, which adds value to the overall package. Free shipping sweetens the deal further at the current pre-order price point.

Real-world Performance

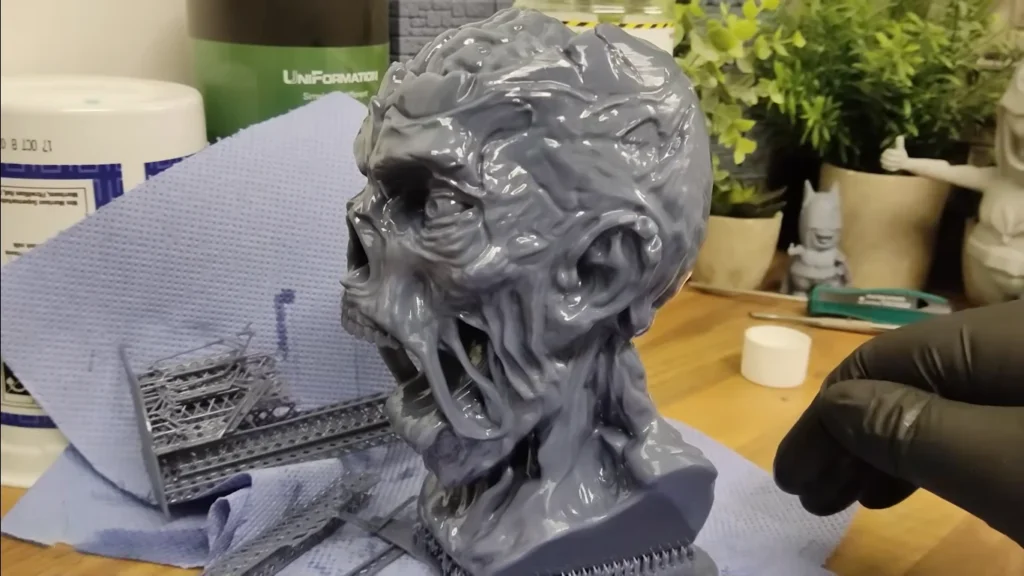

The Mercury Plus V3 has significantly streamlined my post-processing workflow. The ability to handle larger prints and the improved cleaning efficiency means less time spent on post-processing and more time actually printing. I’ve found that complex prints with internal structures clean more thoroughly than with manual methods, thanks to the enhanced agitation system.

I’ve run approximately 50 prints through the station during my testing period, ranging from small figurines to large architectural models. The consistency of results has been impressive, with even delicate supports cleaning properly without damage. The curing results have been equally consistent, with no noticeable yellowing or overcuring issues when following the recommended times.

Looking Ahead

While the Mercury Plus V3 represents a significant upgrade in many areas, some aspects warrant consideration. The proprietary nature of the new washing bucket means you’ll need to stick with Elegoo’s specific replacements. Additionally, while the plastic components help reduce costs and increase adjustability, their long-term durability remains to be seen.

Should You Buy the Elegoo Mercury Plus V3?

After extensively testing the Mercury Plus V3, I’ve found that while it’s an excellent wash and cure station, it’s not necessarily the right choice for everyone. Here’s my practical breakdown of who should and shouldn’t invest in this machine.

Buy the Mercury Plus V3 If:

- Ideal for Mid-Sized Printers: Works well with models like the Saturn 4 Ultra and Mars 5, with adjustable brackets and large wash capacity.

- Space-Saving Design: Combines wash and cure functions in one unit, freeing up workspace.

- User-Friendly and Safe: Touch controls, pre-set timers, UV protection, and sealed wash tank make it easy and safe to use.

Don’t buy the Mercury Plus V3 if:

- Not for Larger Printers: Not suitable for printers with larger build plates, like the Jupiter.

- Budget-Friendly Alternatives: Occasional users might save more with manual cleaning and sun curing.

- Noisy Operation: The improved impeller system is louder than previous models, which may not suit everyone.

Final Thoughts

The Elegoo Mercury Plus V3 is available at a pre-order price of $129.99, with a regular retail price of $162. This pricing places it in an interesting position in the market, especially considering its expanded capabilities and larger capacity compared to previous models.

As a standalone unit, the Mercury Plus V3 delivers an impressive post-processing experience, particularly with its enhanced washing system and comprehensive 360-degree curing setup. The increased capacity and dual cleaning modes make it an excellent choice for users of mid-sized printers like the Saturn 4 Ultra and Mars 5 Ultra. However, users of larger format printers like the Jupiter series should note that they’ll need to remove prints from the build plate for cleaning.

For those deciding between this and other post-processing solutions, the Mercury Plus V3 makes a compelling case for itself, especially at the pre-order price point. The combination of washing and curing functions in a single unit, enhanced by features like the 24 powerful 405nm UV lights and reflective mirror system, provides substantial value. That said, potential buyers should consider their specific needs – particularly regarding build plate compatibility and cleaning solution preferences – when making their decision.

It’s easy to recommend the Mercury Plus V3 for users seeking a comprehensive post-processing solution that balances convenience with capability. However, those with specific requirements, such as ultra-large format prints or specialized curing needs, might want to explore our broader recommendations for resin printing post-processing equipment. The Mercury Plus V3 excels as an all-in-one solution but, like any tool, works best when matched appropriately with your specific printing setup and requirements.

Yes, this is actually one of the biggest improvements in the Mercury Plus V3. I’ve tested it extensively with the Saturn 4 Ultra build plate, and it fits perfectly in the washing chamber using the new adjustable bracket system. The expanded 7.5L tank capacity easily accommodates the larger build plate, and the brackets keep it securely positioned during cleaning. It’s worth noting that the brackets can handle build plates up to 10 inches, so you’re future-proofed for most standard and mid-size resin printers.

Unfortunately, no – and this is something I learned the hard way when trying to swap buckets between units. The Mercury Plus V3 uses a completely redesigned wash bucket system that isn’t backward compatible with V2 buckets. While this might seem inconvenient if you’re upgrading, the new bucket design offers better sealing, improved agitation, and significantly larger capacity. If you need replacement buckets, you’ll need to get the V3-specific versions from Elegoo.

After using both regular resin and water-washable resin, I have a bit of info to share: you can effectively just use water to wash it off but in the cleaning station, using a fluid mix of half IPA and half water gets ultimately better results. Its mighty impeller system is optimized to work best with IPA or equivalent rinsing solutions. If you’re using water-washable resin to avoid IPA entirely, you might be better off hand-washing under running water. However, if you’re open to using a small amount of IPA mixed with water, the Mercury Plus V3 can still provide excellent cleaning results with water-washable resins.

Through extensive testing, I’ve found that curing times vary significantly based on your specific needs. While Elegoo’s recommendation of 2 minutes for models under 30mm is a good starting point, I’ve developed a more nuanced approach:

- Miniatures (20-30mm): 2-2.5 minutes works perfectly

- Medium prints (30-100mm): 3-4 minutes typically gives the best results

- Large or complex prints (>100mm): 5-8 minutes, depending on thickness and detail

- Clear or transparent resins: Add 1-2 minutes to these times

The new 360° UV system with reflective mirrors makes curing more efficient than previous models, but it’s still worth testing with your specific resin and model types to find the sweet spot.

This is one of the most common questions I get, and after weeks of testing, I’ve found that IPA longevity depends heavily on your usage patterns. However, I’ve developed a two-stage cleaning process that significantly extends IPA life:

- Pre-wash prints in a separate container with already-used IPA to remove the bulk of uncured resin

- Use the Mercury Plus V3 with fresh IPA for final cleaning

With this method, I’ve managed to extend my main tank’s IPA life to about 30-40 prints before needing replacement. Signs that it’s time to change include:

- Cloudy or overly dark solution

- Prints feeling tacky after washing

- Visible resin particles floating in the solution

The larger 7.5L capacity actually helps here – the increased volume means the solution gets saturated more slowly than in smaller wash stations.

Nikko Jenkins is a technology journalist based in the US, covering tool reviews and comparisons across North America, Europe and Asia, particularly 3D Printers. His concise, insightful articles on the latest innovations help readers worldwide make informed tech decisions. Jenkins’ expertise and engaging style have made him a respected voice in the global technology landscape.

Feel free to reach out to me at nikkojenkins@360techinsights.com.